LNS Research Names Innovapptive a Proven Provider in their Solution Selection Matrix™ for Connected Frontline Workforce Applications

Download Now

Download Now

Connected Worker Solutions for Maintenance, Operations and Warehousing

We Bring Your Frontline Workforce,

Back-Office and Assets Together

We've partnered with some of the world's leading brands like AkzoNobel, Marathon and Newmont over the last decade to digitalize asset management, MRO spare parts and operations processes. With our help, these organizations are connecting frontline workers to back-office systems like never before.

20%

Increased Work Capacity

30%

Reduced Downtime

60%

Reduced Maintenance Backlog

30%

Improvement in Warehouse Productivity

Trusted By

Trusted By

Our Solutions

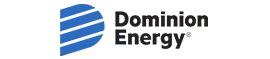

Maintenance

Increase wrench time and improve worker productivity

Mobile Capabilities

Work Order Management, Inspections and Checklists, MRO Spare Parts ManagementDesktop Capabilities

Planning and Scheduling, Spare Parts Control Center, Work Instructions Authoring

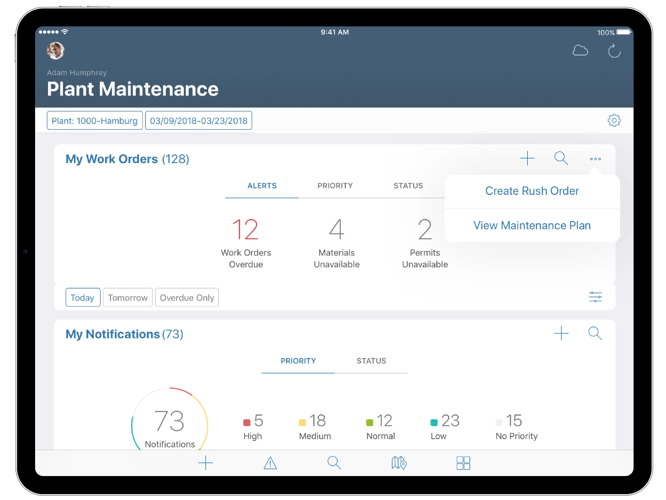

Operations

Eliminate paper and feed real-time data into your ERP

Mobile Capabilities

Operator Rounds, Inspections and Checklists, Fixed Asset Tracking, Materials Management

Desktop Capabilities

Planning and Scheduling, Operator Rounds Planning, Work Instructions Authoring

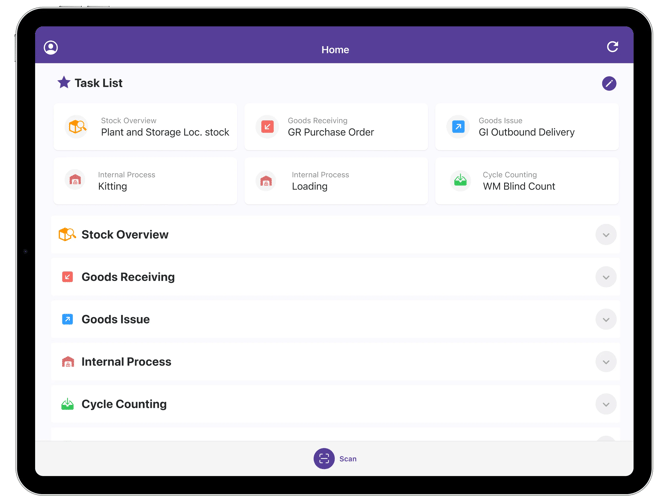

Warehousing

Improving inventory accuracy

Mobile Capabilities

Warehouse & inventory management, raw materials, finished goods, MRO parts

Desktop Capabilities

Warehouse Operational Dashboards, Spare Parts Control Center

Since the start of the project we have been nothing but pleased with the quality of the service we've received from Innovapptive. The whole team from the sales team to the project team have been nothing but supportive

I'd say Innovapptive for us has been a reliable product. It was easy to implement, the service has been good. So I would recommend checking them out if you're looking for some help with your workflow.

Innovapptive mobile solutions. It's Great. It's a one-stop shop for all the engineering activities and administrative duties basically. It allows us to keep everything current and up to date.