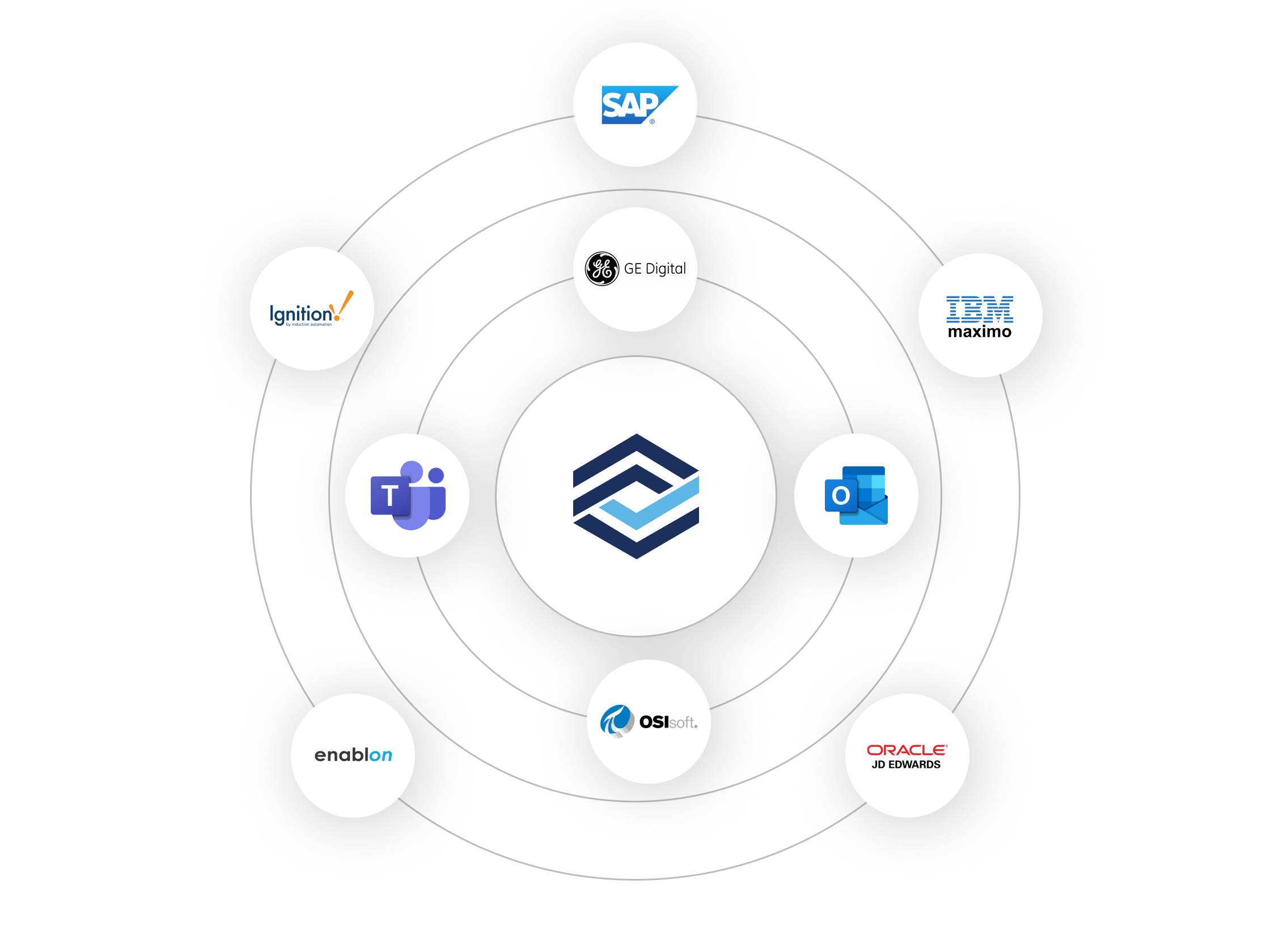

Proactively prevent compliance risks by setting up intelligent trigger rules based on sensor or historian data. Monitor temperature, pressure, or any critical parameter—and act before issues escalate.

Automate routine inspections by scheduling rounds the moment thresholds are breached. With direct integration to OT/IT systems, ensure instant response and continuous compliance.

.webp)

.webp)

.webp)

.webp)