Improve Safety, Reliability & Asset Life with Mobile Operator Rounds

In asset-intensive industries, optimizing production processes while ensuring compliance with strict safety and operational standards is crucial.

Introducing mRounds - a mobile operator rounds platform designed to empower production operators with real-time field data, enabling them to streamline operations, improve efficiency, and drive productivity to new heights.

Trusted by Operators and Frontline Workers Worldwide

Mobile Enabled Operator Rounds

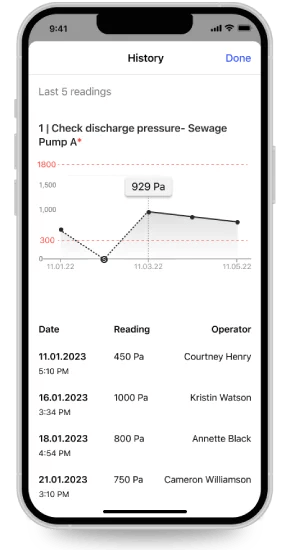

Gain Real-Time Visibility into Operating Conditions

- Eliminate outdated and inefficient paper-based data collection

- Conduct rounds using mobile devices or tablets

- Track progress in real time and make informed decisions based on plant data

- Improve asset reliability, data quality, safety, compliance, and productivity

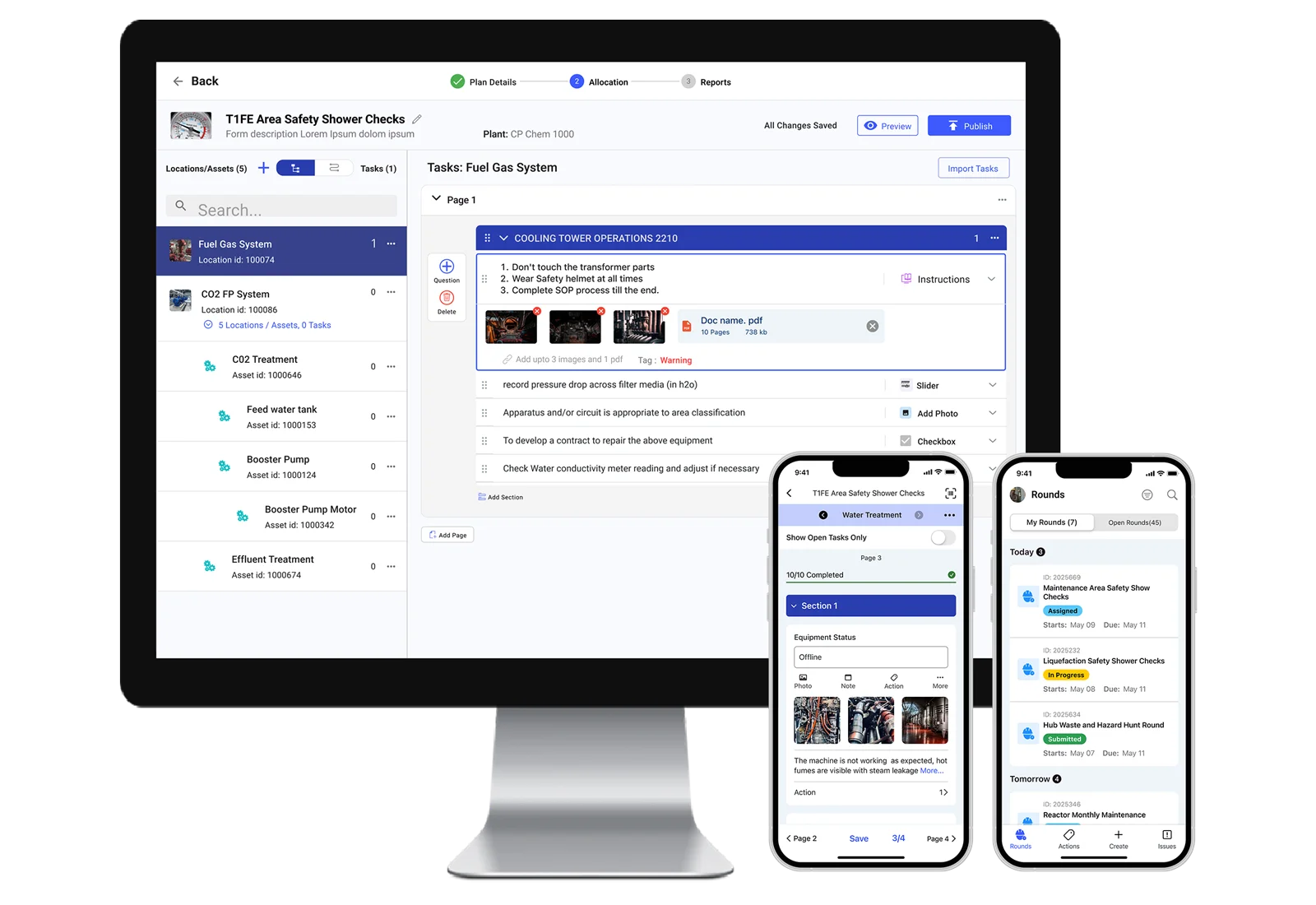

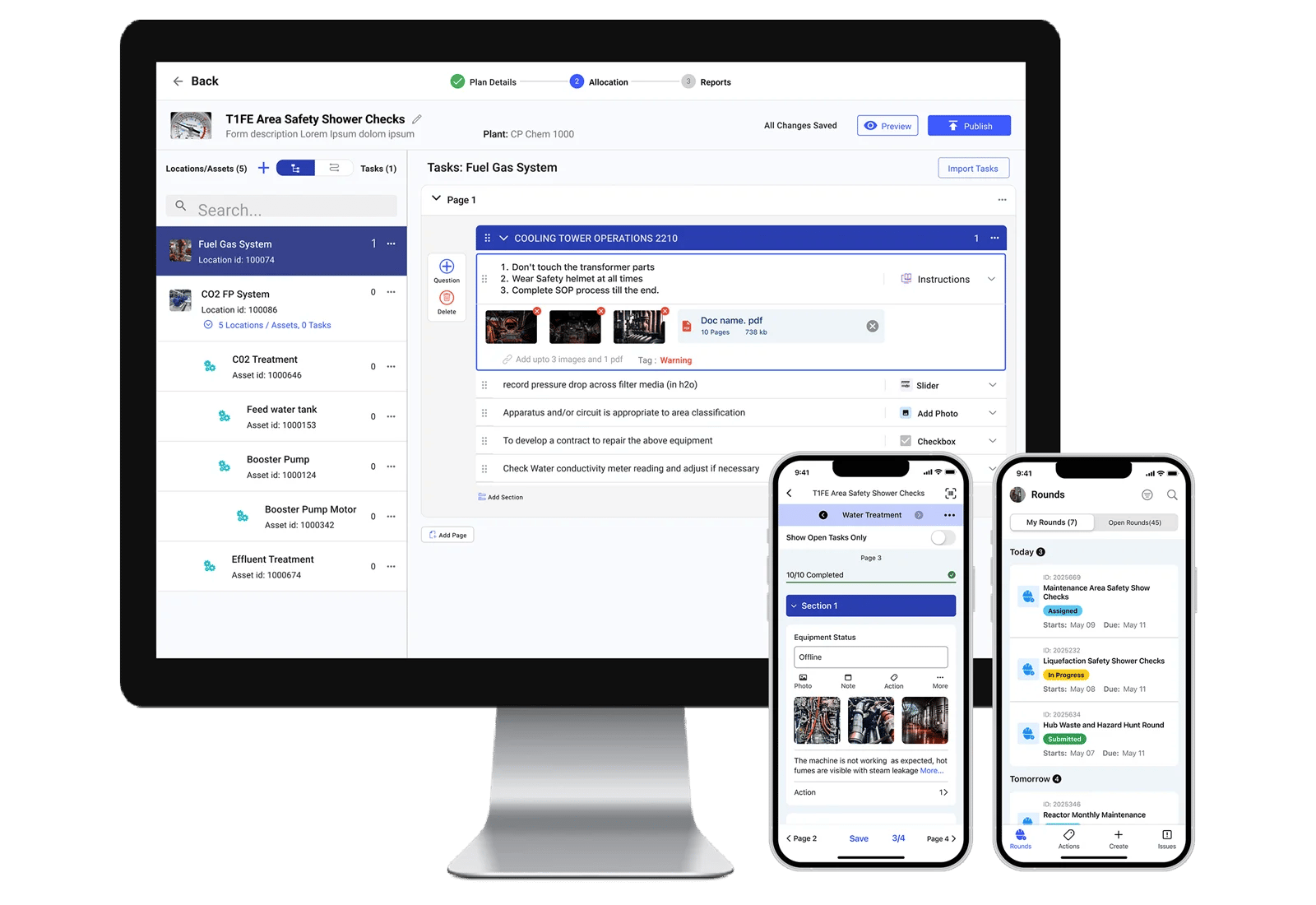

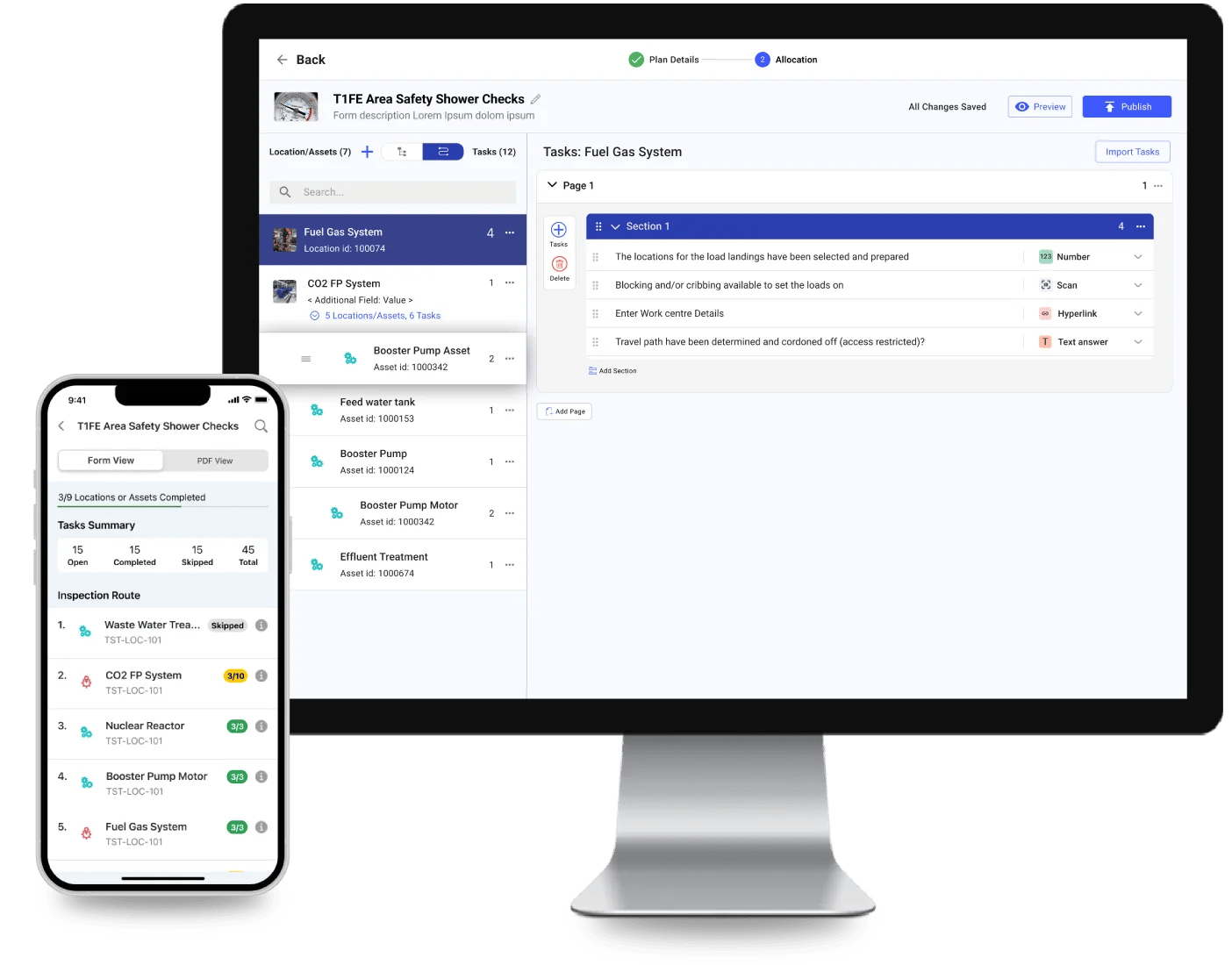

Drag and Drop Rounds Builder

Simplify Creating and Configuring Rounds with an Intuitive Drag and Drop Rounds Builder

- Empower administrators and supervisors to easily design and modify rounds templates using a user-friendly interface.

- Add, remove, or rearrange inspection points, checklists, and tasks to create comprehensive rounds that capture the critical data relevant to your operations.

- Save time and effort with a visual interface that allows you to intuitively design rounds workflows.

- Maintain consistency and standardization across operator rounds with predefined templates and standardized inspection points.

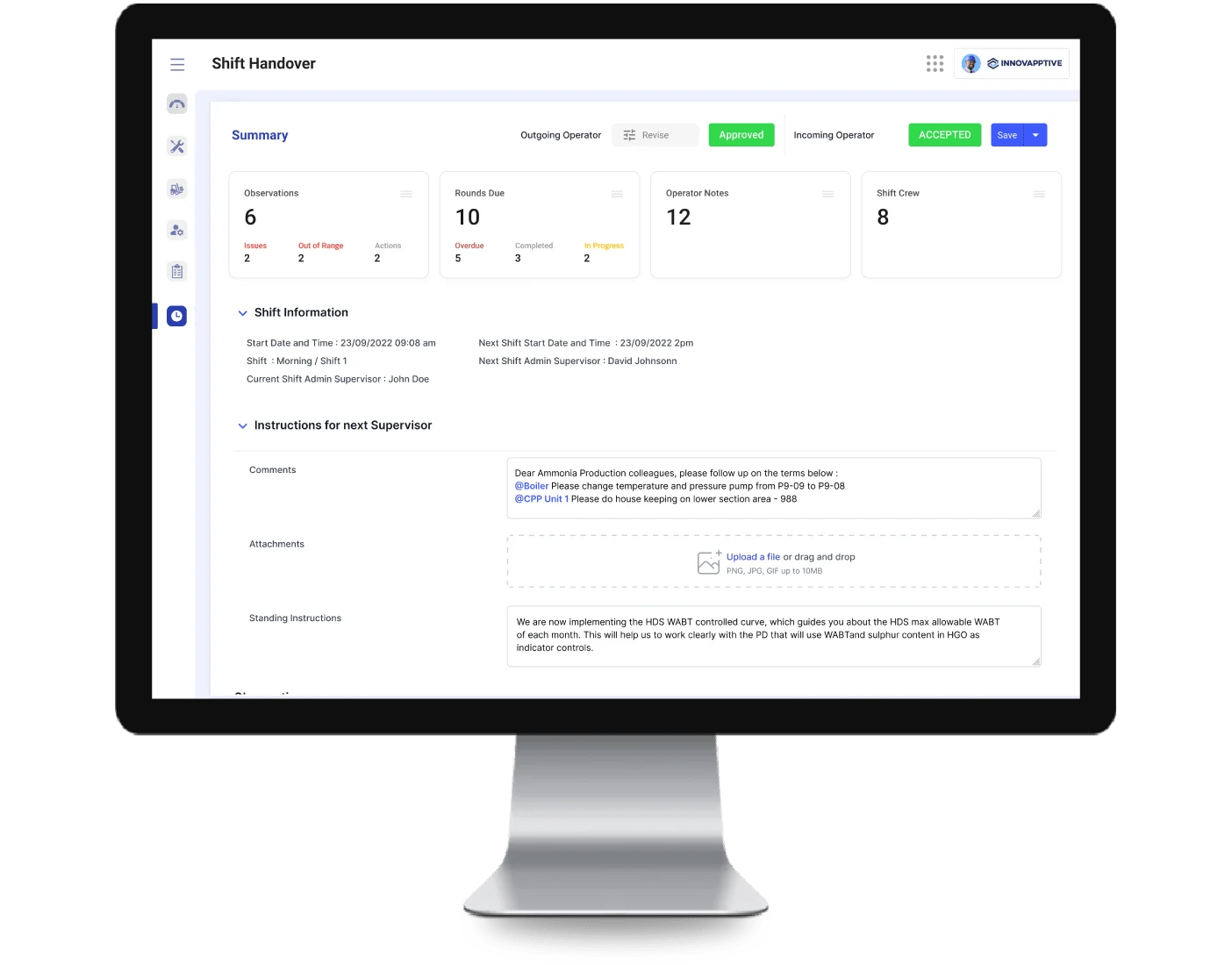

Integrated Shift Turnover

Seamlessly Transition Between Shifts with Integrated Shift Turnover Functionality

- Operators can easily hand over critical information, including ongoing tasks, completed rounds, observations, and outstanding issues to the incoming shift.

- Event based reporting of anomalies or out-of-spec conditions onto shift turnover reports automatically

- Ensures smooth collaboration, reduces communication gaps, and helps maintain continuity in operations, ultimately enhancing productivity and preventing errors.

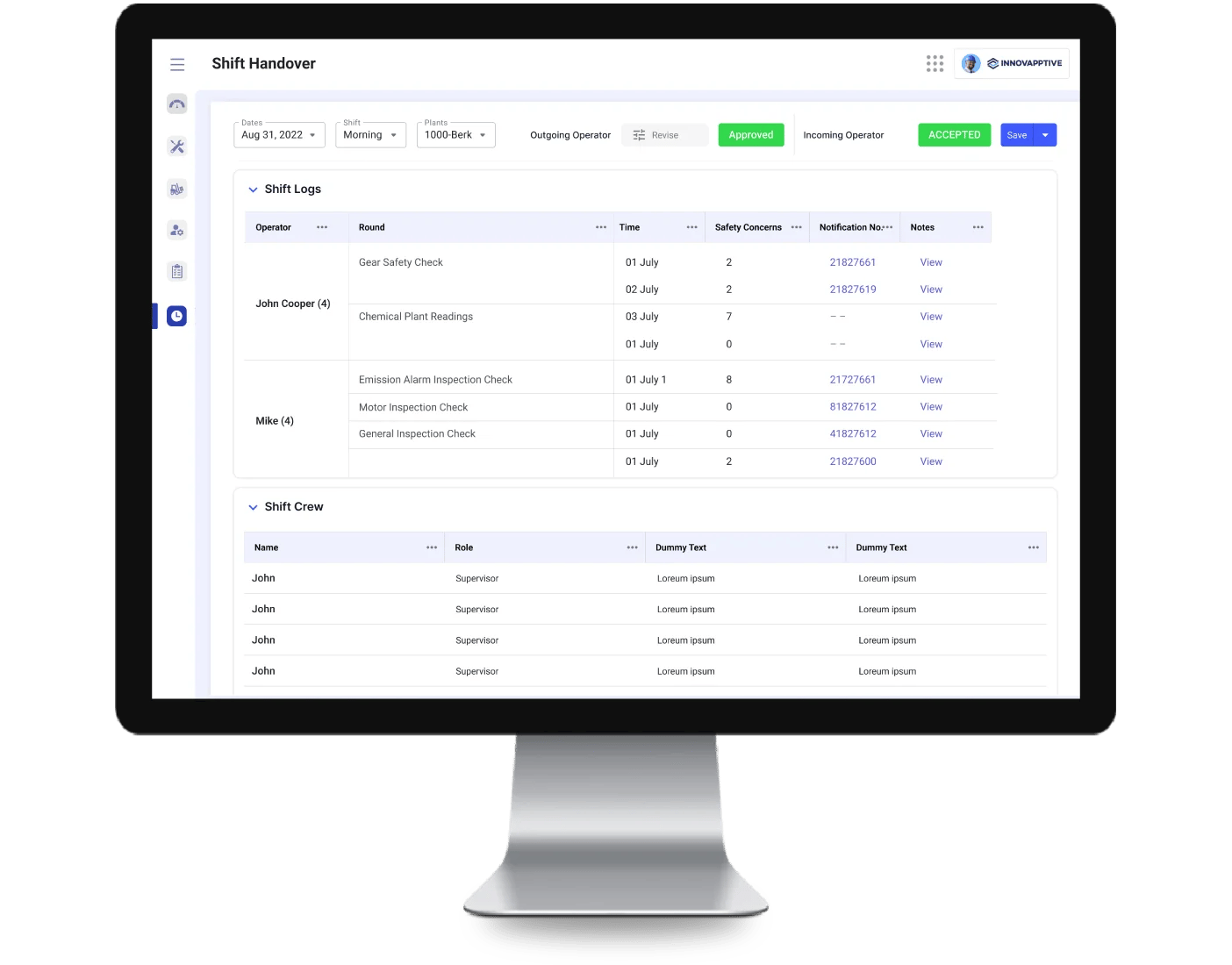

Operator Shift Logs

Shift into Seamless Collaboration and Precise Accountability

-

Keep a comprehensive record of operator activities and shift logs with our Operator Shift Logs.

-

This feature allows operators to document their actions, tasks performed, and observations throughout their shift.

-

Ensure compliance with regulatory requirements, track historical data, and facilitate effective analysis for continuous improvement.

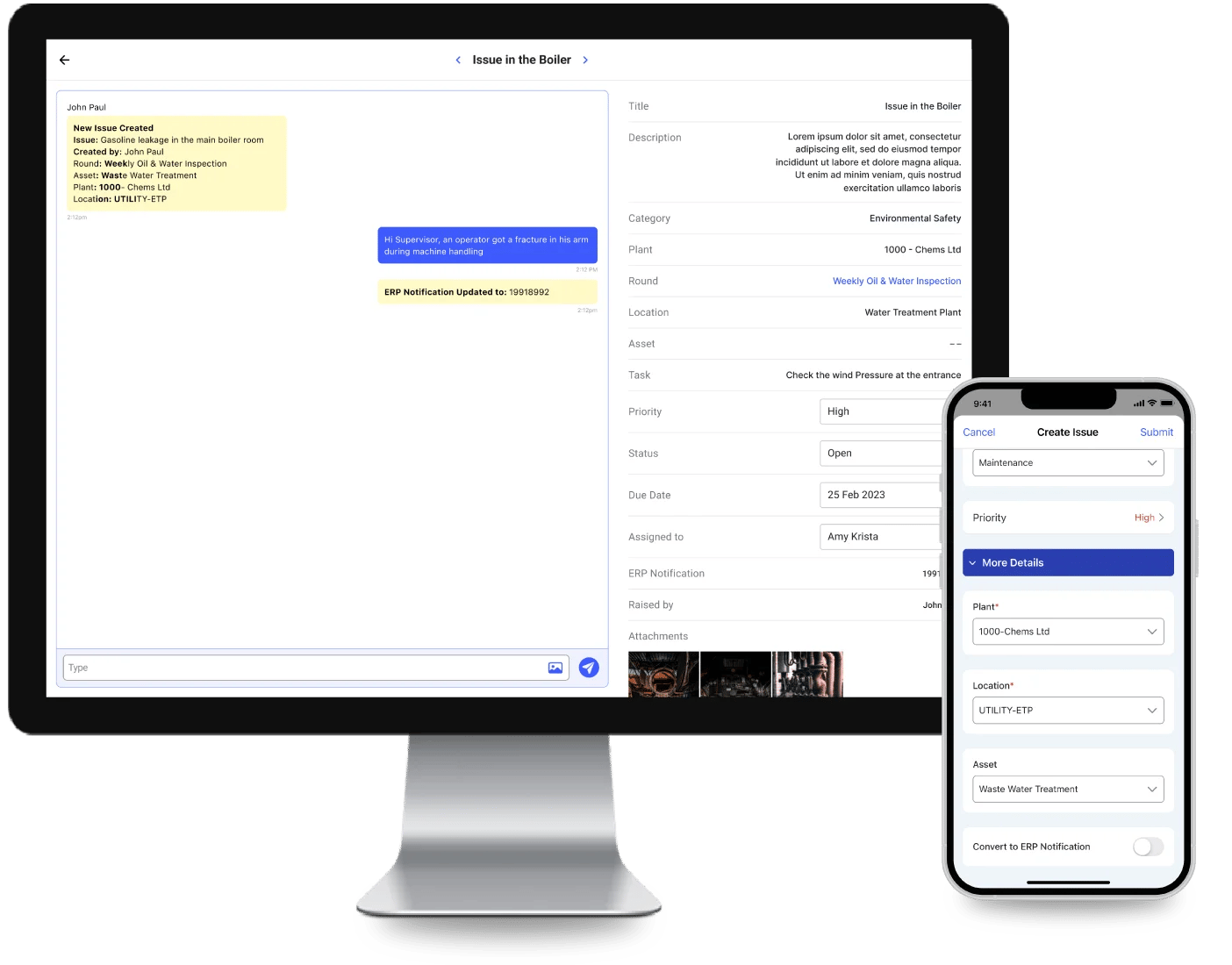

Work Notification Entry

Streamline the Process of Capturing and Managing Work Notifications with Ease

- The mobile operator rounds solution allows operators to enter work notifications directly from the field.

- Whether it's an SAP maintenance request, equipment malfunction, or safety hazard, operators can quickly report and document issues, triggering immediate action from the relevant teams.

- This streamlined workflow enables prompt issue resolution and helps prevent potential disruptions.

Predictive Rounds

Leverage the Power of Predictive Analytics to Optimize your Operator Rounds.

-

Seamless Integration with Asset Performance Management (APM) solutions outlining the condition state and

failure risks -

Leverage inputs from an APM or ACM (Asset Condition Monitoring) solutions to determine priorities, due dates, and required measurements to be taken

-

Maximize efficiency, prioritize operator activities, and proactively address potential issues, minimizing downtime and enhancing operational reliability.

Why Innovapptive For Your Mobile Rounds

Digitize Rounds Planning

Create detailed operator rounds plans, assignments, and routes – no paper involved.

View What the Round Looks Like Before Issuing

See round plans as they will look to the operator in the field.

Import Fields from

Previous Rounds

Save authoring time by reusing tasks and questions.

Customize Responses

Tailor questions and answers to ensure rounds are completed correctly and accurately.

Configure Units of Measure

Set measurements to conform to specific location requirements.

Establish Measurement

Limit Alerts

Sending an automatic notification when a measurement exceeds a pre-set limit.

Set Up Mandatory Fields

Ensure fields can’t be skipped and must be entered before a round can end.

Require Evidence and Justification

Add logics so that an operator must include attachments or photos.

Create a Digital System

of Records

Produce a customized, comprehensive report to share with stakeholders.

Gain Speed and

Agility in Responses

View pictures and notes; issue notifications, and make assignments in real time.

Follow-up

Roadmap Reduces Risks

Create notifications and reminders for any completed task.

No Internet Connection?

No Problem

Complete tasks offline, then rapidly sync the application when connectivity is re-established.

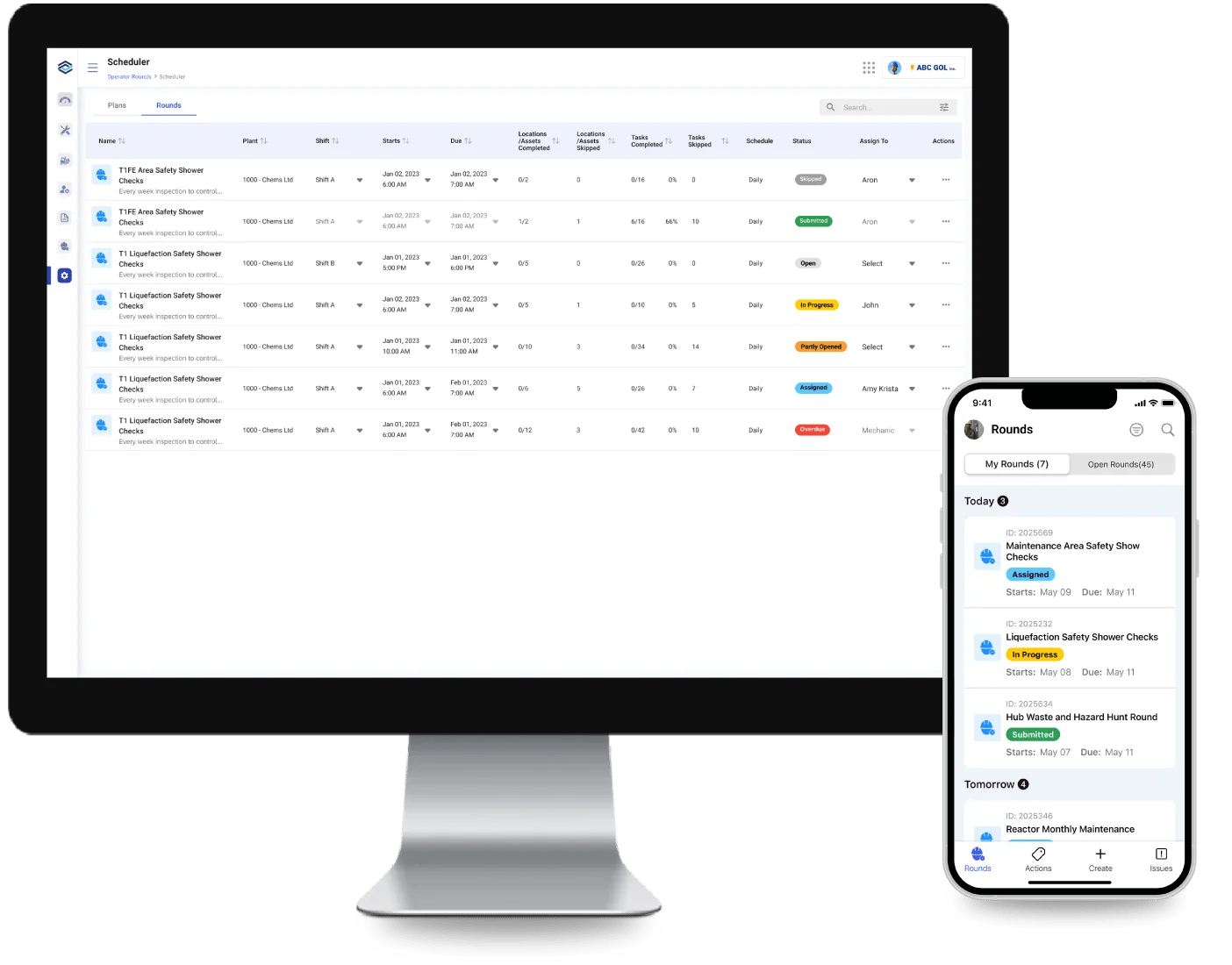

A Flexible, Agile, and Totally Digital Operator Rounds Process

- Plan, schedule, and issue a round from anywhere at any time

- Configure a digital form to meet the company’s business needs or new regulations in less than 30 minutes

- Avoid the need for coding or technical knowledge and get productive from the get-go

Is mRounds the Right Solution for You?

Innovapptive serves industries like oil and gas, chemicals, utilities, mining, and manufacturing. Here is how your organization can leverage mobile operator rounds.

Oil and Gas

- Use at any oil and gas facility, either onshore or offshore: an upstream drilling site, a midstream processing plant or pipeline, or a downstream refinery

- Identify potential equipment issues in the early stages

- Take proactive action before they contribute to costly incidents

- Ensure production assets remain up and running and workers remain safe

Chemicals

- Use at any chemical processing facility, including giant petrochemical plants, agricultural chemicals factories, or process chemical plants.

- Accurately monitor asset health in real time

- Gain valuable early warning to potential issues

- Ensure production assets remain up and running and workers remain safe

Mining

- Use in open-pit, surface, subsurface, or in-situ mines

- Spot areas of concern regarding equipment condition or safety

- Take prompt action to resolve the situation before an incident occurs

- Ensure production assets remain up and running and workers remain safe

Utilities

- For use in electric generation, power transmission, natural gas distribution, or water/wastewater facilities

- Gain greater operational visibility into current conditions

- Take fast remedial action when a potential issue is spotted

- Reduce equipment downtime incidents and promote a safer workplace

Manufacturing

- Use in any manufacturing plant: assembly, casting, forging, stamping – from automobiles and machinery to durable goods and consumer products

- Understand current operating and reliability conditions in real time

- Take appropriate actions an issue causes downtime or a safety problem

- Ensure production assets remain up and running and workers remain safe