High-Quality Data.

High-Velocity Reliability.

High-quality data accelerates reliability, strengthens planning, and improves every decision.

Booth 117, International Maintenance Conference 2025

Booth 117, International Maintenance Conference 2025

December 8th to 11th

December 8th to 11th

JW Marriott Marco Island Beach Resort

JW Marriott Marco Island Beach Resort

Proudly Exhibiting as Silver Sponsors

Proudly Exhibiting as Silver Sponsors

Book Your 1:1 Strategy Session

Our Clients Trust Innovapptive for Maintenance Excellence

-

38%

Reduction in Unplanned Downtime

-

~$12.5M

Savings in Annual Maintenance Costs

-

20K

Technicians Empowered for Peak Performance

The reliability gap: AI fails without high-quality maintenance data

This is what happens when data quality is sub-standard.

Supercharge Your Reliability Today

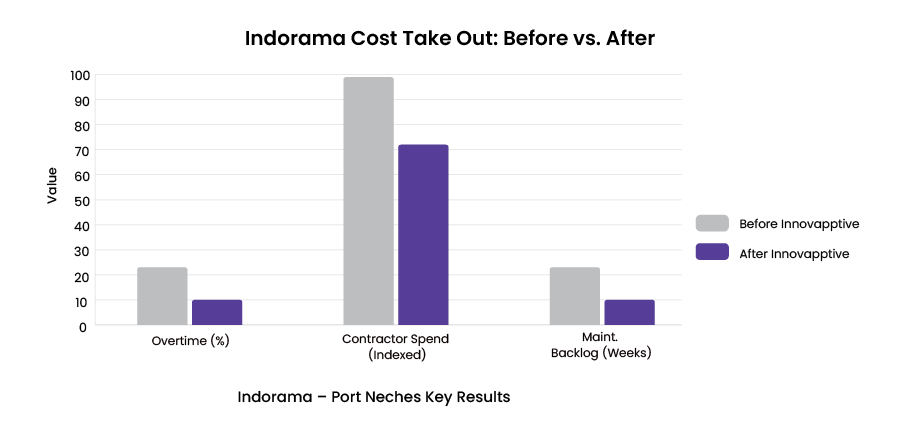

Indorama achieves $12 Million in cost take-out with Innovapptive

Real Stories. Real Impact. See How Industry Leaders Succeed with Innovapptive.

Micah Mosley

Operational Excellence Manager, Indorama Ventures

Emily Hebert

Director of Operational Excellence

Lee Whiteley

Regional Field Operations Manager, AkzoNobel - World’s Leading Provider of Advanced Petrochemical Solutions

Don’t let disconnected data cost your plant millions

Poor data quality drives unplanned downtime, repeat failures, and inflated contractor reliance. Planners overestimate job durations because they lack real-time condition data. Reliability engineers spend hours reconciling conflicting records instead of preventing the next failure. Clean data reverses these trends and gives executives a measurable financial justification for transformation.