Prevent Unplanned Downtime, Avoid Costly Disruptions

Frontline teams are your first line of defense against downtime—empowered with AI and a truly connected workforce, they can detect, act, and prevent faster.

Trusted by Industry Leaders to Drive Operational Efficiency

Downtime Isn’t Just Delay

It’s a Cost. We Prevent It.

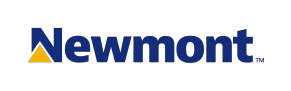

Detect Failures Before They Disrupt Production

- AI & Computer Vision Detection: Spot issues the human eye misses—before they cause downtime.

- Rule-Based Triggers: Auto-launch alerts when thresholds are crossed.

- Instant Quality Notifications: Flag defects in real time for faster fixes.

Repair Faster and Reclaim Wrench Time

- AI-Led Autonomous Maintenance: Technicians get guided SOPs and real-time AI help.

- Connected Department Workflows: Sync maintenance, stockroom, and supervisors—avoid delays and miscommunication.

- Integrated EHS & Approvals: Automate checks and permits—no more wait time.

-1-3.webp)

Avoid Downtime from Part Delays

- Mobile Inventory Access: View and manage live stock levels directly from the field.

- Kitting & Staging: Pre-bundle and stage parts for upcoming jobs—no last-minute scrambles.

- Faster Part Access: Get the right parts to the right place—at the right time, every time.

%20(1).webp)

Prevent Downtime from Skill Gaps

- Digital Work Instructions: Step-by-step guidance helps anyone perform like an expert.

- Tribal Knowledge Capture: Preserve and share experienced know-how across your frontline workforce.

- AI-Guided Support: Real-time help when workers are stuck—no more delays or dependencies.

-1%20(1).webp)

Stop Repeat Failures with Root Cause Fixes

- Digital RCA & 5 WHYs: Standardize investigations and eliminate guesswork in root cause analysis.

- Kaizen Action Tracking: Turn improvement ideas into action with clear ownership and follow-through.

- Cross-Shift Visibility: Keep teams aligned on fixes with shared learnings and digital handovers.

Turn Downtime into Uptime—Every Shift, Every Site

Unplanned downtime drains productivity and profits. Digitize inspections, shift handovers, and maintenance execution to catch issues early, resolve them faster, and recover hundreds of lost hours annually—no added risk, just higher uptime.

Real Stories. Real Impact. See How Industry Leaders Succeed with Innovapptive.

"The user experience has been fantastic. Our operators have adapted to using the device for operator rounds very easily. Even some of our folks who have been here 30-35 years experienced can pick up the device and use it."

Micah Mosley

Operational Excellence Manager, Indorama Ventures

"“I appreciated the sales, project, and executive teams' great efforts for the company win. It's the best solution and a very trusted and strong partnership for the company - a big win.”

Jinmoon Son

IT Manager, Lotte Chemical USA

"Innovapptive mobile solutions are great. They’re a one-stop shop for all the engineering activities and administrative duties. They allow us to keep everything current and up to date."

Lee Whiteley

Regional Field Operations Manager, AkzoNobel

"We hadn’t had much luck with mobile plant maintenance solutions in the past. Our frontline maintenance technicians didn’t want to use them because of poor UI/UX. They’d rather use paper, meaning we received a poor return on investment and achieved none of our operational objectives."

Cary Brunson

Principal Advisor, Asset Management at Newmont Mining

"We wanted to make our workers more autonomous, independent, and proactive. We wanted to give them data at their fingertips. With Innovapptive’s mobile maintenance solution, they’ll get that."

Emily Hebert

Director of Operational Excellence, Sabert Corp.

"One of the greatest benefits has been our ability to index over 1,200 photos and 420 videos in just 3 years, directly during work order execution. This has made information transfer smoother and has helped standardize work order templates across operations."

Thierry Copin

Director of Continuous Improvement, Tafisa Canada

"Since the start of the project we have been nothing but pleased with the quality of the service we've received from Innovapptive. The whole team from the sales team to the project team have been nothing but supportive"

Christopher Lathrop

Enterprise Solution Architect, Par Pacific

“I’d say hands down, that was the best technology implementation in project management. Everything was on time, on budget. Quite frankly, I hadn’t seen anything like it before in my 10+ year career. I loved it."

Alton Echols

Director of O&M Programs, Loudoun Waters