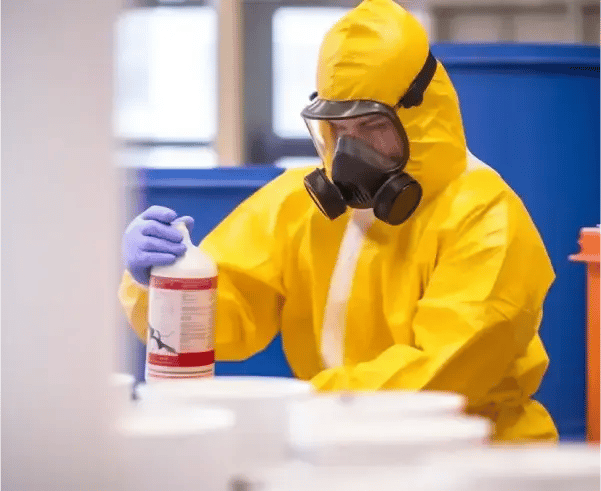

The #1 Connected Worker Platform for Chemical Operations—No Contest!

Stop Compliance Breaches, Prevent Safety Hazards & Achieve Peak Efficiency with AI-Driven Work Execution Meet Sustainability Targets & Reduce Emissions Faster!

Trusted by Industry Leaders to Drive Operational Efficiency

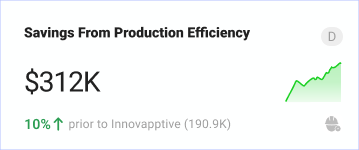

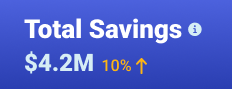

One Unified Platform. Real ROI—$12M+ EBITDA Gains per Site.

Indorama’s Results with a Connected Worker Platform:

- ✅ 130 → 93 contractors — cut execution waste

- ✅ 24% → 10% overtime — better preventive planning

- ✅ +10% inventory accuracy — on a $30M MRO budget

Chemical industry leaders trust Innovapptive’s Connected Worker Platform to boost safety, cut costs, and ensure compliance—sustainably

Request A Demo15K+

Frontline Workers Empowered

45+

Global Enterprises Trust Us

10M+

Work Orders Digitized

120+

Sites Transformed

Empowering Every Frontline Team in Your Plant

For Operations Teams

Stay 100% compliant with AI-driven operator rounds triggered by OT data. Avoid compliance breaches, prevent process deviations.

For Maintenance Teams

Digitize work orders, predictive maintenance, and scheduling with AI. Maximize wrench time, cut unplanned downtime.

For Reliability Teams

Boost asset uptime with AI-driven failure prediction, condition monitoring, and automated compliance tracking. Minimize risks in hazardous chemical processes.

For Warehouse Teams

Ensure 99% inventory accuracy with real-time material tracking, barcode scanning, and AI-driven demand planning. Reduce stockouts and material delays.

For EHS Teams

Ensure 100% safety compliance with AI-driven hazard detection, chemical exposure tracking, and digital permits-to-work. Cut incidents, eliminate regulatory fines.

Crack the Code: Turn O&M Costs into EBITDA Wins

Chemical plants spend billions on maintenance—yet up to 30% sees zero ROI. One site spends 10.7% of revenue, another just 4.5%, creating a $500M EBITDA gap.

Transforming Chemical Industry Operations with AI & Digital Innovation

Safety & Regulatory Compliance

Reduce Unplanned Downtime

Cost & Productivity Optimization

Address Workforce & Skill Gaps

Real-world results from leading industrial plants using Innovapptive to run smarter.

- 17-01-2025

Global Energy Firm Boosts Operational Efficiency with AWS and Innovapptive

- 18-10-2024

Indorama’s Connected Frontline Worker Digital Transformation

- 17-10-2024

Par Pacific Deploys Innovapptive Mobile Solutions to Boost Collaboration, Efficiency, and Productivity

- 16-10-2024

Shell Boosts Warehouse Efficiency and Accuracy with Innovapptive’s mInventory

- 18-06-2024

Cut Downtime and Achieve Record Production with Innovapptive’s Intelligent Connected Worker Platform

Read Our Latest Blogs Curated by Industry Experts

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal maintenance are more urgent than ever. Manufacturers, oil & gas, utilities, chemicals, and other process and discrete industries face growing complexity. To stay competitive, plants must reduce downtime, improve productivity, and ensure compliance. These are no longer optional. This is where a robust connected worker platform can be a game-changer for you.

Read More