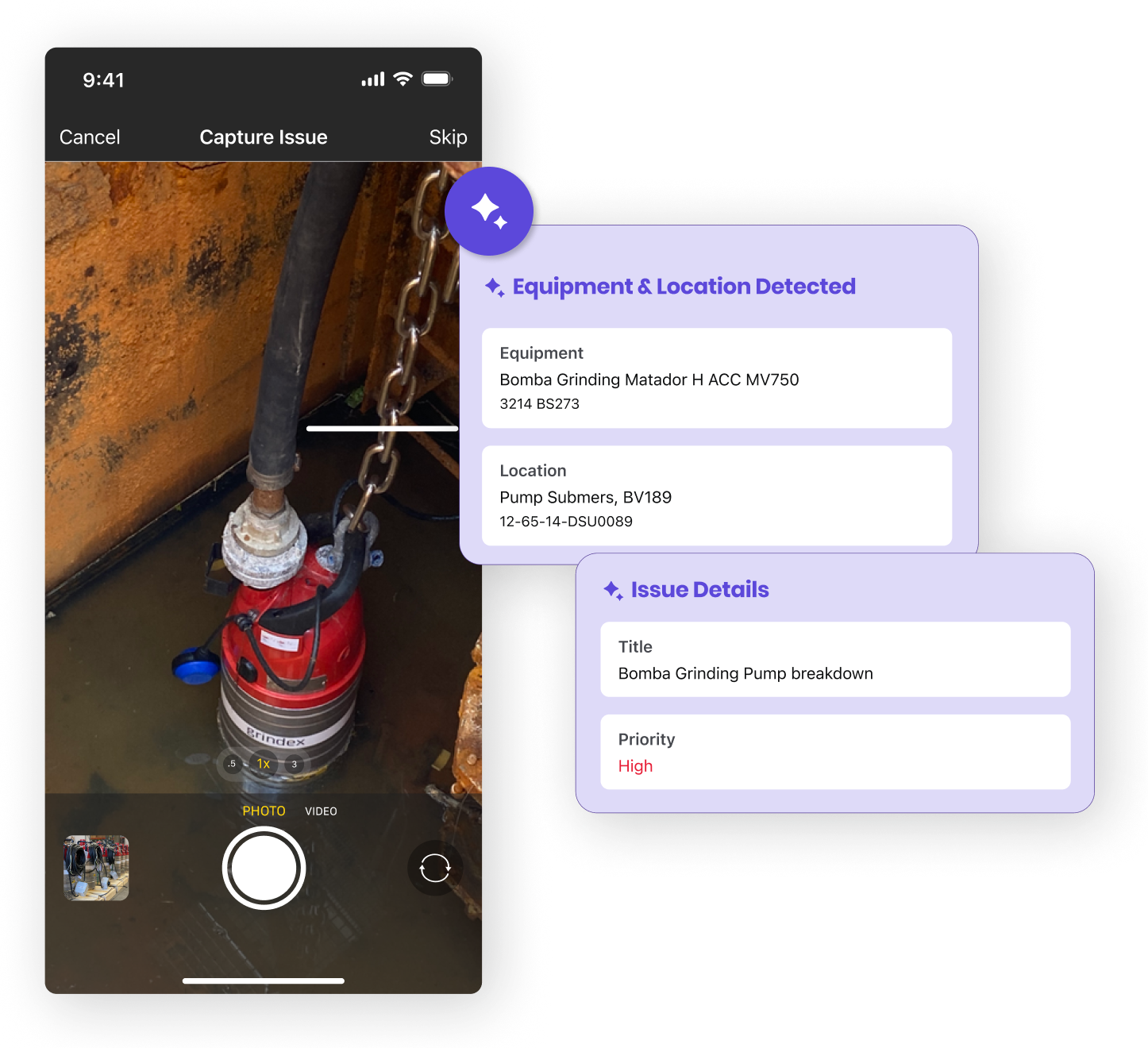

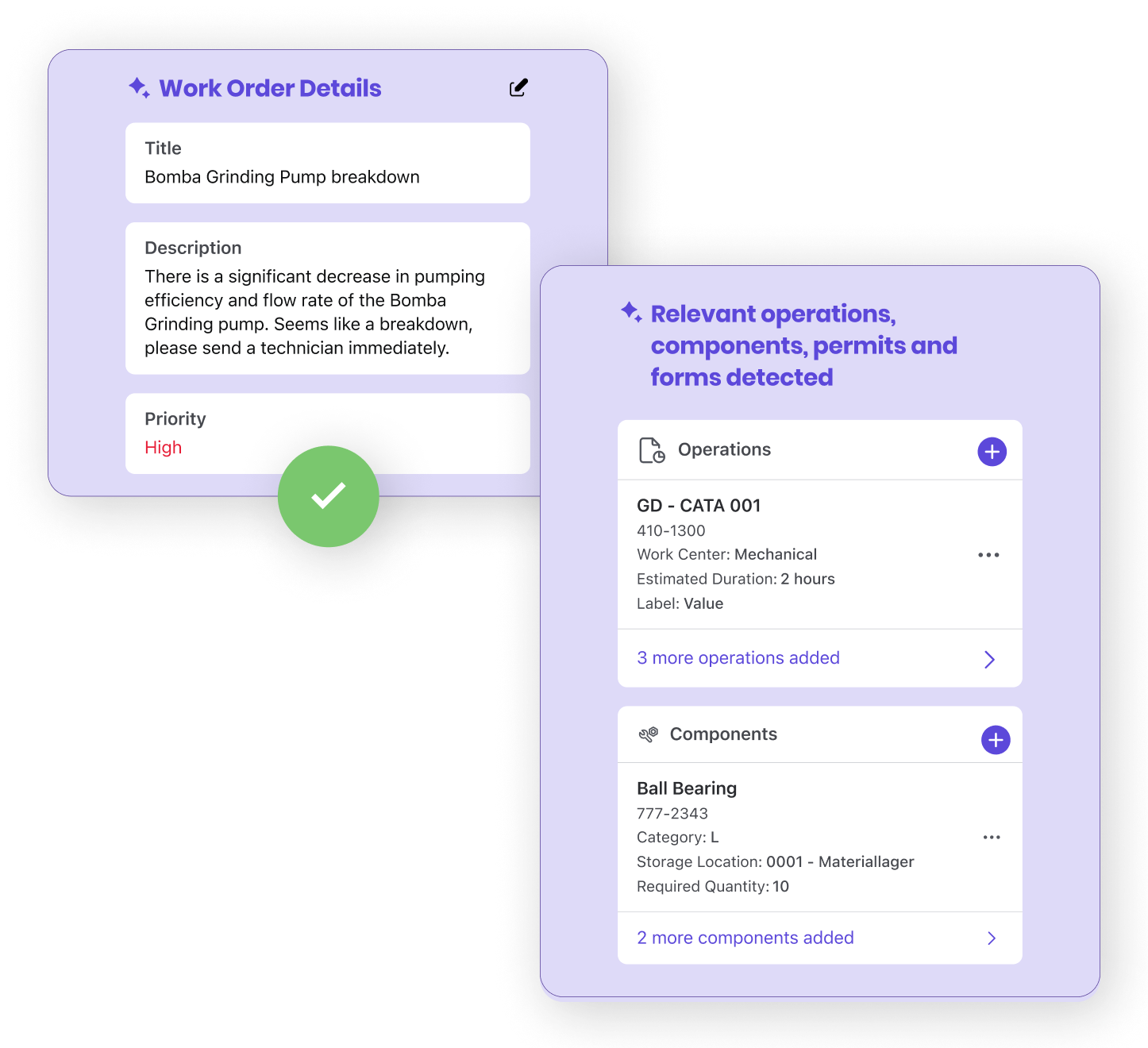

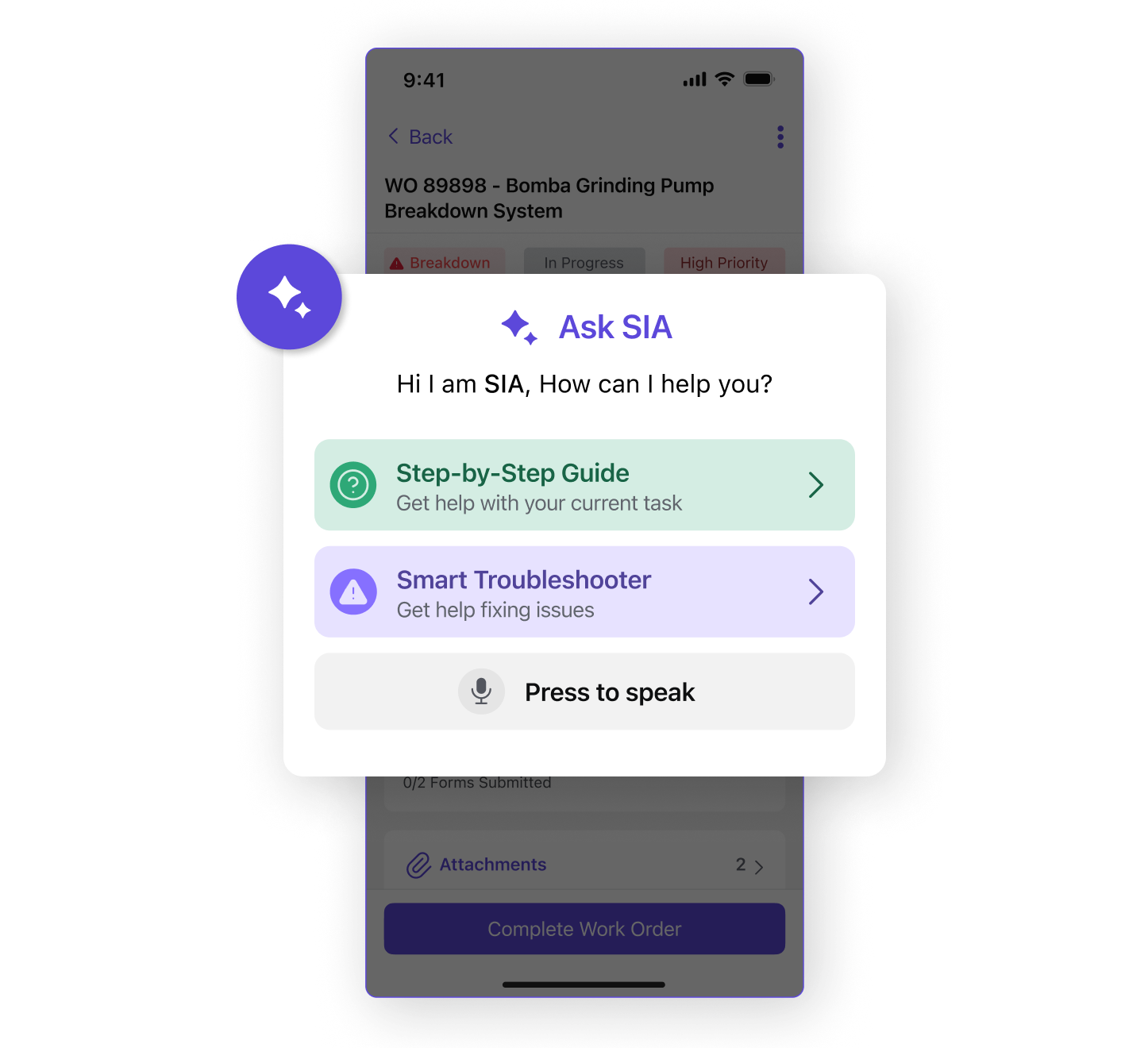

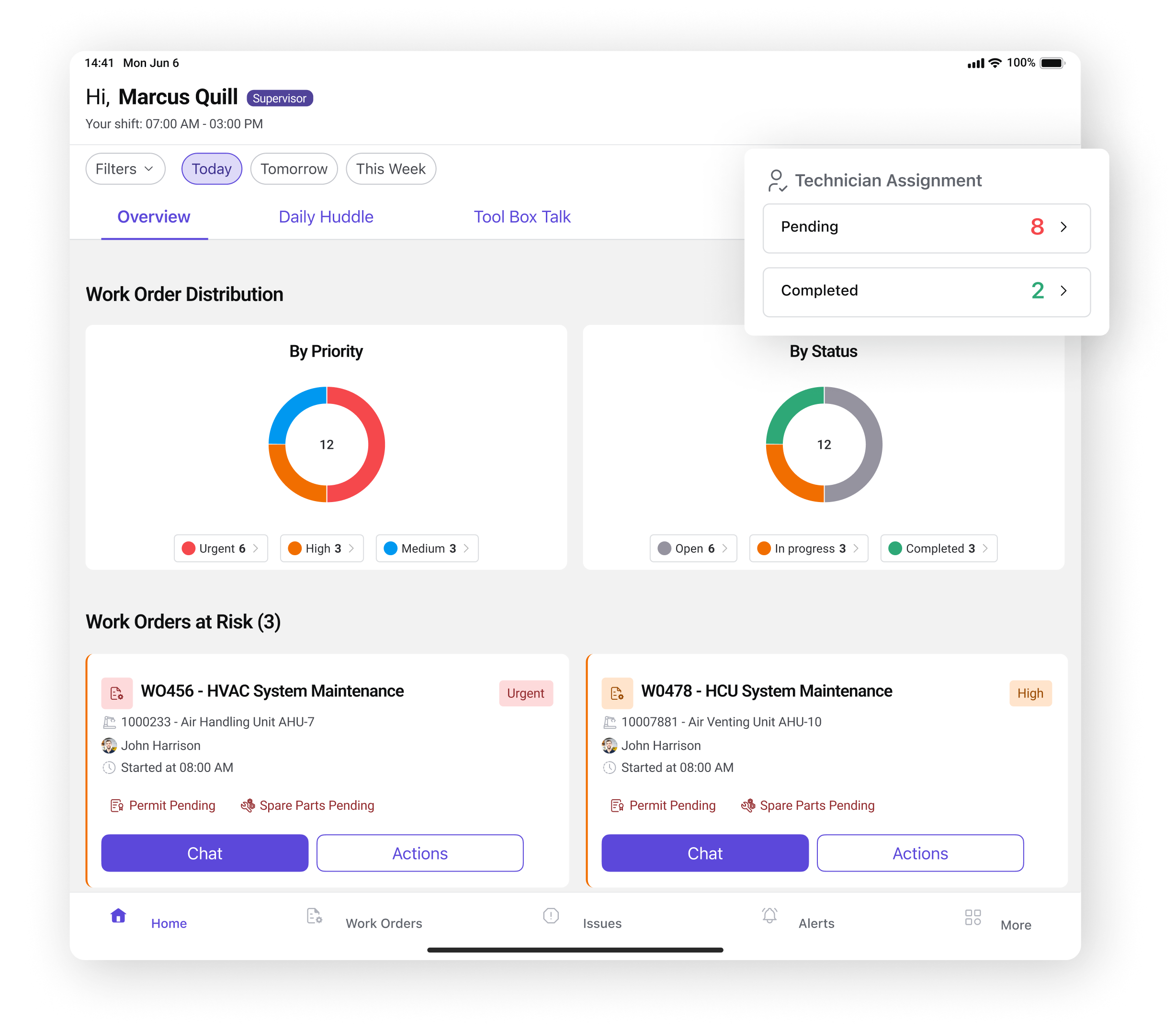

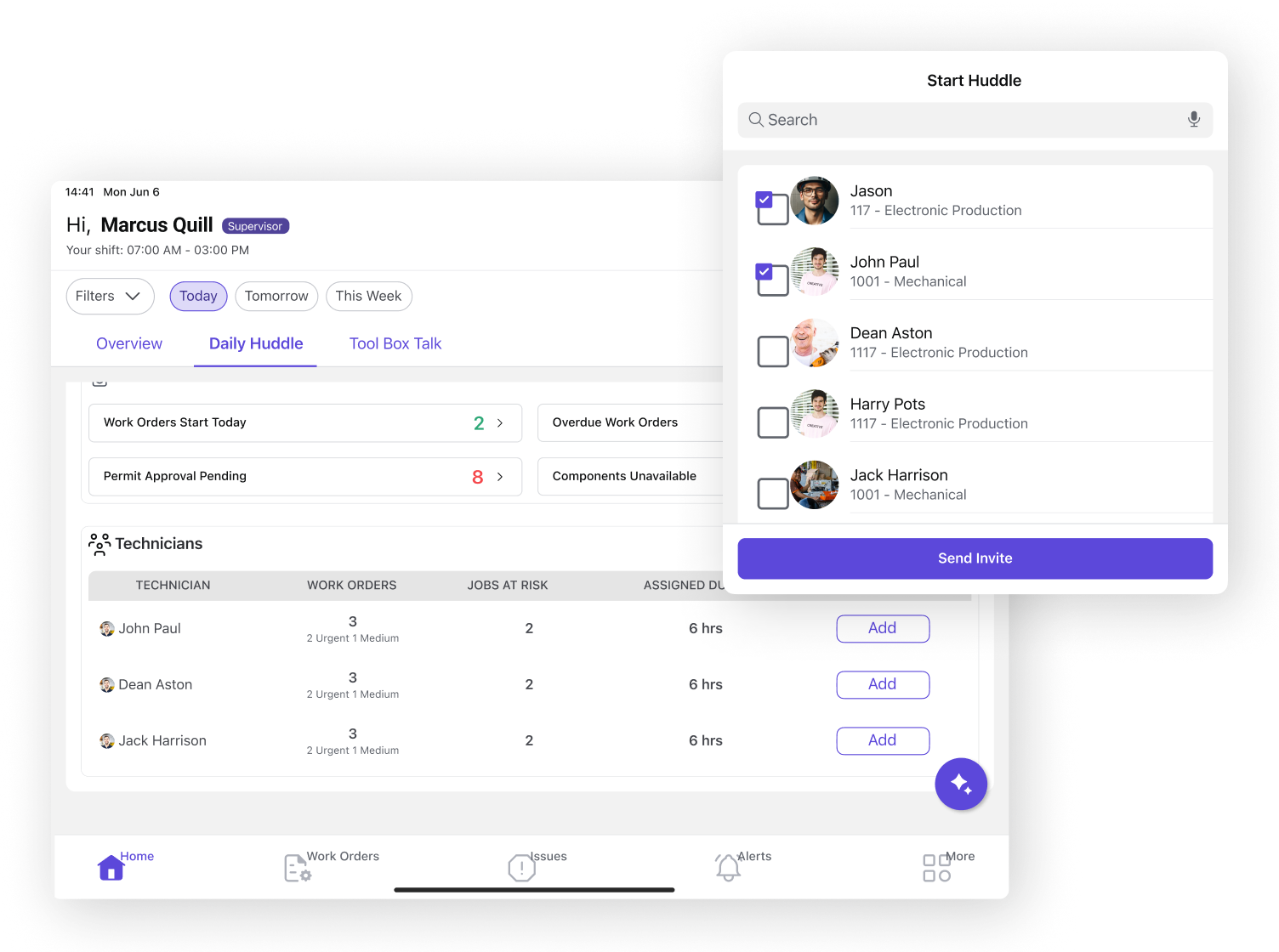

Equip your technicians with a Mobile Maintenance App to seamlessly access jobs, track work orders, and complete inspection checklists—all in one place. AI-driven recommendations boost efficiency and cut downtime, so every repair is faster and smarter.

Complete jobs with AI precision—maximize efficiency, minimize delays.

.webp?width=400)

.png)