Beyond the Warehouse Walls: Unlocking the Real Value of Mobility

Warehouse operators and companies involved in supply chain & logistics are struggling with competing pressures that may adversely affect their profitability such as…

● Customer demands for competitive pricing

● Shipping at lower costs

● Rapid response times

● Increasing supply chain complexity

Holding unnecessary inventory in warehouse ties up a lot of cash, however, optimizing inventory effectively can drive a tremendous business value. Companies need to make sure that they have a better visibility and management of inventory to workflows and space utilization. To do this, they must identify process gaps and inaccuracy in inventory transactions, otherwise, organizations end up overpaying to manage their inventory.

For organizations to ensure effective warehouse operations and meet today’s connected customers, who expect faster delivery, freeing up capital while maintaining optimal inventory levels is crucial. They need to find the perfect balance to prevent stock-outs, improve response time and asset utilization, reduce inventory and enable faster order cycle times. With advancing technology and changing customer expectation, warehousing is becoming complex day-by-day. To maintain efficiency in operations, warehouses need to ensure that there is no room for mistake.

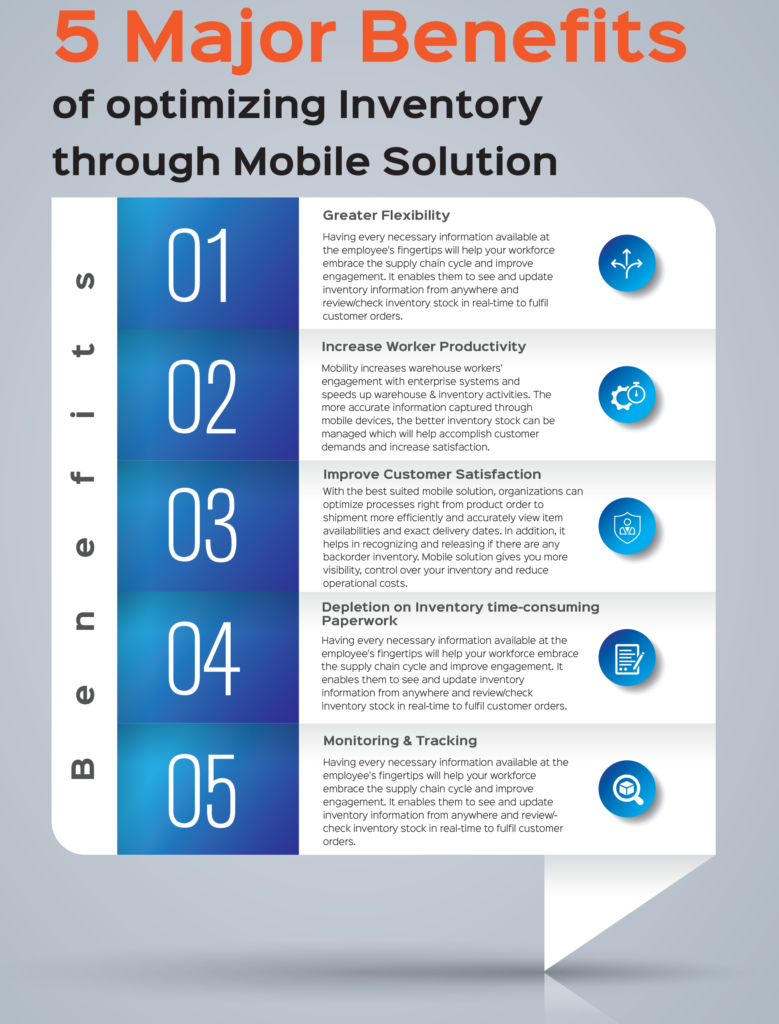

To be competitive, companies must meet their customers’ needs ahead of schedule and incorporate a cutting-edge technology that allows them to manage the supply chain operation more accurately and efficiently. Mobile technology is no longer a nice to have, it is a MUST have in modern business. It can cover the ambit of warehouse and inventory operations from managing an optimum level of inventory to finished goods to reaching out to customers. Mobile technology is a pivotal tool for managing warehouse and inventory operations more effectively. It helps companies drive efficiency, increase productivity, and reduce costs by eliminating unnecessary paperwork.

Here comes the real part.

You understand the importance of Mobility in warehouse & inventory operations and its major benefits. It is now time for choosing the right system for your warehouse functions.

Let’s make mobility work for you!

Innovapptive understands the pain of today’s organizations in managing their warehouse & inventory operations. Fortunately, we offer a mobile application for Mobile Inventory & Warehouse Management - mInventory, which helps increase stock accuracy, assist employees in managing and completing customers’ orders with real-time updates and avoid delinquencies and/or errors in the processes. mInventory joins seamlessly; effortlessly syncing with your SAP IM/WM or EWM to recover and process transactions as well as establish a unified communication setup. Warehouse transactions are completed on the devices, either through scanning barcodes or keying inputs, which updates the ERP in real time.

If you would like a demo of Innovapptive’s mInventory(Mobile Inventory and Warehouse Management) solution,![]() please click on the link. Alternatively, if you would like to discuss with an Innovapptive solution expert, you can reach out to us by emailing us at sales@innovapptive.com or you can reach a sales representative at (713) 275-1804.

please click on the link. Alternatively, if you would like to discuss with an Innovapptive solution expert, you can reach out to us by emailing us at sales@innovapptive.com or you can reach a sales representative at (713) 275-1804.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”