Boosting Field Workforce Utilization with a Connected Worker Solution

Industrial plants and manufacturing facilities are suffering from a lack of collaboration between the maintenance department and the spare parts warehouse. This deficiency can result from reliance on inefficient manual data-sharing processes or the use of incompatible mobile frontline worker applications. Can an integrated connected worker solution offer an answer while raising productivity and field workforce utilization?

What Is a Connected Worker Solution?

Frontline, connected workers utilize mobile technology to accomplish data gathering and sharing faster, better, cheaper, and safer than traditional manual processes. These can include:

- Smartphones

- Tablets

- Wearables

- Drones

A connected worker solution uses integrated mobile technology to increase cross-departmental cooperation, such as between the maintenance and spare parts warehouse. It can provide:

- Greater operational visibility throughout an enterprise

- Insight into the potential cause of a problem and its effects

- A way to assign maintenance resources and check spare part availability

- Improved collaboration to undertake recommended actions in a timely fashion

Introducing the Innovapptive Connected Worker Solution

Innovapptive is a digital transformation and connected worker platform leader. The company focuses on mobile-first solutions for asset-intensive industries, such as:

- Oil and gas

- Chemical processing

- Mining and minerals

- Utilities

Innovapptive offers the mWorkOrder and mInventory mobile frontline worker applications. mWorkOrder delivers end-to-end visibility into the maintenance work order process, while mInventory improves the warehouse management process.

The Innovapptive Connected Worker Platform (CWP) accelerates the adoption of digitalization by field workers and enhances real-time operational visibility across the organization. The solution supports on-field, data-driven decision-making by creating a single source of truth that seamlessly integrates master data from various back-end systems and real-time operational data from connected devices. It provides field workers with actionable and reliable contextual information to do their assigned work easily and safely. The platform also enables them to work efficiently as a team by sharing information in real-time.

The Innovapptive CWP offering delivers end-to-end connected worker solutions by leveraging the company’s cross-industry expertise across engineering services, mobile solutions, and digital practices coupled with an ecosystem of alliances and partners. Some of the key benefits of this solution include:

- Data-driven operations and better on-field actions

- Improved work quality and reduced downtime

- Real-time visibility to maintenance and the warehouse

- Reduced risks and errors

- Improved compliance and safety

- Greater economies of scale

What Separates Innovapptive from the Rest of the Field?

Innovapptive’s solution offers several advantages over the competition. These include:

- Easy configuration and customization

- Superior user interface/user experience

- Works in online and offline mode

- Integrates with SAP and IBM Maximo

The Innovapptive Connected Worker Platform also offers three control centers:

Maintenance Control Center (MCC) - Integrated with mWorkOrder. Supervisors and managers can assign work orders to maintenance workers, send notifications, see real-time spare parts availability and kit status, and monitor work order progress from a single interface. Field workers can execute work orders within a paperless process.

The Work Instructions Authoring Tool - Integrated with mWorkOrder. Maintenance planners and supervisors can create and attach digital work instructions to work orders to ensure work is completed right the first time with no reworks or backlogs.

Spare Parts Control Center (SPCC) - Integrated with mInventory. Digitizes warehouse processes to ensure maintenance teams receive the right parts at the right time to increase productivity. Supply chain managers can use the SPCC to assign and monitor warehouse tasks such as kitting parts for work orders.

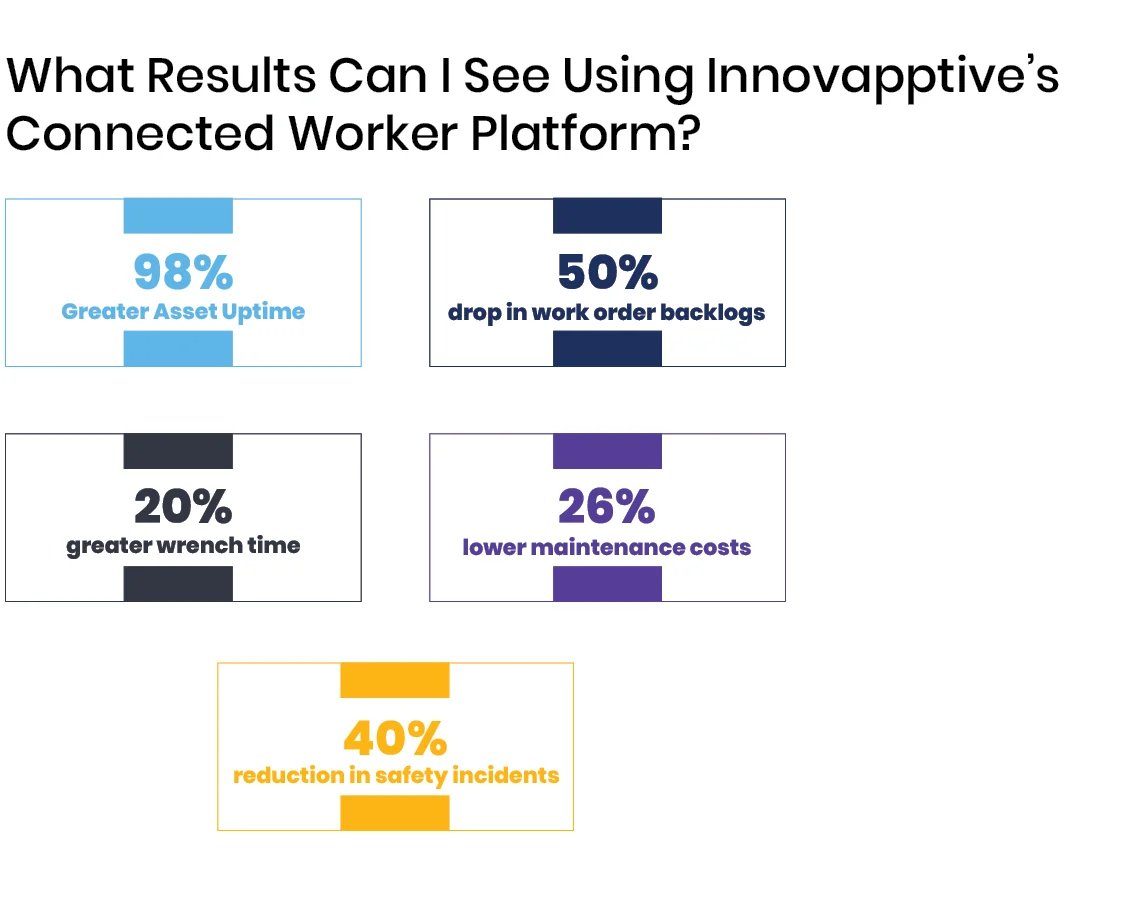

Take out the opening sentence in the graphic and title it as Benefits of a Connected Worker Solution Our ebook, The Innovapptive Connected Worker Platform: Complete End-to-End Visibility and Process Control, offers additional details on the solution’s features and benefits.

Discover the Power of the Innovapptive Connected Worker Platform

Connected workers aren’t just using technology to just do their jobs or stay in touch with co-workers or engage with colleagues online; they’re using it to be more efficient and productive at work and throughout the rest of their day. Schedule a free demo today or call us at 844-464-6668.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”