Industry 4.0 vs. Industry 5.0: What’s the Difference? And Why Should I Care?

One Industrial Revolution is coming to a close and another one looms on the horizon, ready to reshape our world in ways we've never seen before. Yes, the much vaunted and discussed Industry 4.0 is about to give way to something even more profound. It's called Industry 5.0 and it’s about more than just machines and tech buzzwords; it's about the future of how we make things and how we work. You might wonder, "What's all the fuss with these strategies; we haven’t even settled in from the last revolution and here’s another one?" Don’t fret. We're diving into the heart of this. We're breaking down the cool stuff and the big changes that could make or break businesses, and why it's important for you to stay informed. This is where the future starts, and trust me, you want to be in the know.

So, To Start, Just What Is Industry 5.0?

Before we jump into the nitty-gritty, let's lay down the basics. Industry 4.0, the Fourth Industrial Revolution, revolutionized manufacturing by introducing cyber-physical systems, leading to unprecedented levels of automation and connectivity. It was all about smart factories leveraging IoT, AI, and big data analytics to streamline operations and decision-making processes.

Enter Industry 5.0—where the plot thickens. Building on the technological advancements of its predecessor, Industry 5.0 marries these innovations with human ingenuity, bringing back the human touch to automation. It emphasizes the collaboration between humans and robots, steering towards personalized production, sustainability, and enhanced creativity.

What Does Industry 5.0 Bring to the Table?

Industry 4.0 stood firmly on four pillars:

- Interconnectivity: Through IoT and cyber-physical systems, creating a web of communication between devices and humans.

- Information Transparency: Leveraging digital twins for real-time insights and decision support.

- Technical Assistance: Automating tedious tasks and providing decision-making support.

- Decentralized Decisions: Enabling machines to make autonomous decisions based on real-time data.

Industry 5.0 introduces new focal points:

- Human-Centric Design: Prioritizing the enhancement of human skills and creativity.

- Sustainability: Emphasizing eco-friendly manufacturing processes.

- Resilience and Flexibility: Adapting quickly to market changes and disruptions.

- Personalization: Customizing products to meet individual customer needs.

Despite their distinctions, both revolutions share a common backbone—technological innovation. Automation, data analytics, and connectivity are the lifelines of both Industry 4.0 and 5.0. They champion efficiency, productivity, and the transformative power of emerging technologies like AI, IoT, and blockchain.

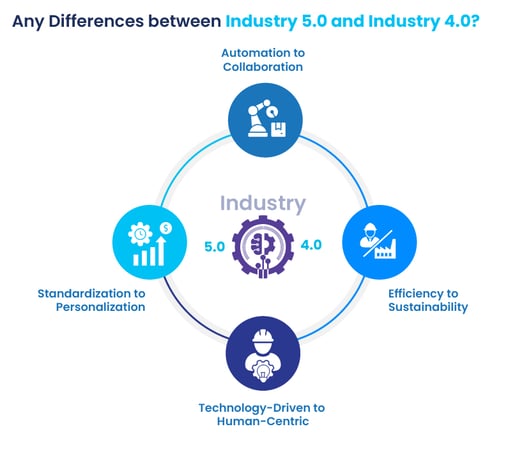

Any Differences between Industry 5.0 and Industry 4.0?

Diving deeper into the distinctions between Industry 4.0 and Industry 5.0, we unveil a transformative narrative that is set to redefine the industrial landscape. This shift is not just about adopting new technologies but reshaping the very essence of manufacturing, making it more inclusive, sustainable, and human-centric. Let's peel back the layers on how Industry 5.0 is poised to revolutionize the work environment for frontline workers and help companies achieve their objectives with unprecedented efficiency and innovation.

- Automation to Collaboration: Industry 4.0 heralded a new era of automation, where machines and algorithms took center stage, performing tasks with precision and speed unmatched by human hands. This focus on automation led to significant gains in productivity and efficiency but often at the expense of human involvement. Workers found themselves either displaced by machines or relegated to monotonous tasks that machines couldn't perform.

Industry 5.0 shifts the narrative from a machine-dominated workplace to a collaborative ecosystem. This collaboration allows workers to focus on complex problem-solving, creativity, and tasks that require a human touch—factors that machines are yet to replicate fully. The integration of human intuition and machine-like precision opens up new avenues for innovation, with workers able to leverage real-time data and machine assistance to improve processes, customize products, and solve problems more creatively.

- Standardization to Personalization: In the world of Industry 4.0, standardization ruled supreme, with mass production models dominating the manufacturing landscape. While this model offers efficiency and cost-effectiveness, it lacks the flexibility to cater to the growing demand for personalized products and experiences.

Enter Industry 5.0, where personalization is at the forefront of production strategies. This new paradigm leverages the collaborative power of humans and machines to create highly customized products without sacrificing efficiency or increasing costs significantly. For frontline workers, this means engaging in more varied and fulfilling tasks, moving away from the monotony of mass production to take part in creating unique products that meet specific customer needs. This shift not only enhances job satisfaction but also allows workers to develop a broader range of skills.

- Efficiency to Sustainability: While Industry 4.0 focused on optimizing productivity and operational efficiency, Industry 5.0 broadens the lens to include environmental and social sustainability. This approach recognizes that long-term industrial success is inseparable from the health of our planet and societies. Industry 5.0 initiatives strive to minimize waste, reduce carbon footprints, and implement renewable energy sources, all while maintaining productivity and profitability.

For frontline workers, this commitment to sustainability can transform the workplace into a more positive, healthy, and meaningful environment. Workers become active participants in eco-friendly practices, from energy conservation and recycling to optimizing production processes to reduce waste. This not only improves the quality of the work environment but also instills a sense of pride and purpose, knowing their daily efforts contribute to a more sustainable world.

- Technology-Driven to Human-Centric: Though technology is a driving force in both Industry 4.0 and Industry 5.0, the latter places a stronger emphasis on human capabilities and creativity. Industry 5.0 technologies are designed to augment human skills rather than replace them. This human-centric approach values the unique insights, decision-making abilities, and creative thinking that human workers bring to the table.

For frontline workers, this means a work life enriched by technology, not overshadowed by it. Workers are empowered with tools and information that enhance their decision-making and creative abilities, making their roles more integral to the innovation process. They're provided with opportunities for continuous learning and skill development, ensuring they remain at the forefront of their fields in an ever-evolving technological landscape.

Key Takeaways

As we pivot from Industry 4.0 to Industry 5.0, it's clear that the latter isn't just an upgrade—it's a reimagining of what manufacturing can be. Here's what to get excited about:

- Empowerment through Collaboration: Industry 5.0 is setting the stage for a world where machines don't replace humans but instead amplify our creativity and efficiency.

- Personalization is the New Black: Tailored products are not just a luxury; they're becoming the standard, and Industry 5.0 is making it possible at scale.

- Sustainability Takes Center Stage: With a focus on eco-friendly processes, Industry 5.0 aligns with the growing global emphasis on sustainability.

- A Secure Digital Ecosystem: Emphasizing cybersecurity, Industry 5.0 ensures a safe environment for this new era of collaboration.

- Job Creation and Skill Enhancement: Far from the job-stealing narrative, this new industrial revolution is poised to create opportunities in fields like RPA, AI, and IoT, emphasizing the need for continuous learning and skill development.

In the face of business disruptions like the COVID-19 pandemic earlier this decade and the shifting demand for personalized products and services, the transformation towards Industry 5.0 isn't just desirable—it's imperative. The organizations that adapt to embrace the principles of flexibility, human-machine collaboration, and sustainability are the ones that will not only survive but thrive in this new era.

OK, Why Haven’t You Started the Transition to Industry 5.0?

The leap into Industry 5.0 represents a pivotal opportunity for companies within the oil & gas, chemical, utility, mining, and manufacturing sectors to not only enhance operational efficiency and productivity but also to foster a more sustainable, innovative, and human-centric work environment. By embracing the collaborative synergy between humans and machines, these industries can unlock unparalleled levels of customization and personalization in their production processes, meeting the evolving demands of the market and consumers with agility and precision.

Furthermore, the shift towards a more sustainable and environmentally conscious manufacturing approach aligns with global efforts to combat climate change, offering companies a chance to lead by example in their respective fields. The transition to Industry 5.0 is not merely an upgrade in technological capabilities; it's a transformative step towards creating more resilient, adaptive, and forward-thinking industries that are prepared to meet the challenges of the future while enhancing the daily work lives of their frontline workers.

Now is the time for industrial companies to embark on this journey, harnessing the full potential of Industry 5.0 to secure a competitive edge in an increasingly dynamic and interconnected world.

Want to Get Ahead of the Industry 5.0 Curve? We Can Help

As you navigate the complexities and opportunities of Industry 5.0, Innovapptive stands at the forefront, ready to guide your company into this exciting future. As a global leader in mobile-first, connected worker technology, we specialize in equipping industrial companies and manufacturing plants with the tools needed to seamlessly transition to Industry 5.0.

Our cutting-edge solutionsoptimize human-to-human and human-to-machine collaboration in operations, maintenance, and warehouse management. This ensures your company can harness the full potential of these advancements to respond quicker to issues, improve decision making, boost productivity, and cut unplanned equipment downtime.

Join us for a free, no-obligation demonstration of our solutions in action and get all your questions answered. Discover how Innovapptive can unlock new levels of productivity and innovation for your organization today.

FAQs

Why is Industry 5.0 important?

Industry 5.0 is crucial because it emphasizes the collaboration between humans and machines, focusing on personalization, sustainability, and enhancing human creativity in manufacturing. This approach aims to balance technological advancement with social and environmental responsibilities, leading to more meaningful jobs and a sustainable industrial future.

What will Industry 5.0 look like?

Industry 5.0 will feature advanced collaboration between humans and robots, with technologies like AI, IoT, and robotics seamlessly integrated into everyday tasks. Workplaces will become more adaptable, focusing on custom solutions and sustainability. Workers will use technology to enhance creativity and innovation, leading to a more personalized and eco-friendly production.

Is Industry 5.0 and Society 5.0 the same?

No, Industry 5.0 and Society 5.0 are not the same. Industry 5.0 specifically refers to the next phase in manufacturing, emphasizing human-machine collaboration. Society 5.0, however, is a broader concept that encompasses the integration of digital technology into all aspects of life, aiming to solve societal challenges through innovation and enhance quality of life for all.

How does Industry 5.0 differ from Industry 4.0?

Industry 5.0 builds on the tech advances of Industry 4.0 but shifts the focus to human-machine collaboration, sustainability, and personalized production. It emphasizes enhancing human creativity and introducing eco-friendly processes in manufacturing.

What new elements does Industry 5.0 introduce?

Industry 5.0 brings a human-centric design, emphasizes sustainability, resilience, flexibility, and personalization in manufacturing, focusing on enhancing human skills alongside technology.

Can Industry 5.0 improve the work environment for frontline workers?

Yes, Industry 5.0 aims to make the workplace more collaborative, sustainable, and fulfilling. By integrating humans and machines closely, it opens up avenues for creative problem-solving and personal growth for frontline workers.

What opportunities does Industry 5.0 offer to businesses?

Industry 5.0 offers businesses the chance to innovate in personalized production, operate sustainably, and remain competitive in a rapidly changing market. It promises enhanced efficiency, creativity, and sustainability in industrial and process manufacturing.

Why is transitioning to Industry 5.0 imperative for companies now?

Adapting to Industry 5.0 is crucial for companies to stay ahead in terms of innovation, sustainability, and meeting the evolving needs of the market and consumers. It's not just an upgrade but a transformation towards a more adaptive, resilient, and forward-thinking industry.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”