How a Connected Worker Platform Can Revolutionize Manufacturing

The global connected worker platform market is expected to reach $12.9 billion by 2027, according to Adroit Market Research. Offering quality improvement, productivity increase, and enhanced safety, connected worker platforms are increasingly adopted by top industries including manufacturing. Given the benefits it brings along, a connected worker solution has the potential to revolutionize manufacturing and prepare organizations for future factories.

What is a Connected Worker?

Enterprise solutions have helped deskbound workers become more productive, data-driven, and efficient than ever over the last two decades. Frontline, deskless workers have been largely forgotten in this digital revolution, forced to perform tasks as they always have: with low-tech, paper-based workflows.

A connected worker solution bridges that gap, directly linking field technicians and warehouse workers to centralized data mechanisms like ERPs and EAM systems. This is about more than just issuing workers a smartphone. Connected worker solutions enable collaboration, information sharing, data capture, and digital work instruction training to empower the frontline worker to accomplish task faster and safer.

Connected worker solutions play a critical role in driving operational excellence for industrial organizations. They bridge the information gap, directly linking field technicians and warehouse workers to centralized data mechanisms like ERPs and EAM systems. This is about more than just issuing the workers a smartphone. Connected worker solutions enable collaboration, information sharing, data capture, and training to empower the frontline worker to accomplish better, faster, and safer. Making frontline workers the center of things—machines, methods, and workflows, a connected worker platform brings everything together to create an integrated ecosystem that improves productivity.

How Does a Connected Worker Platform Work?

Creating a connected workforce encompasses advanced technologies such as digital work instructions, barcode scanning, voice-to-text recognition, and software that is intuitive enough to ensure workers remain engaged and have a high level of adoption.

A connected worker platform integrates the mobile applications of two or more operational groups to provide a single, unified source of accurate, real-time data that delivers end-to-end visibility enterprise-wide, across departments and processes. With a connected worker platform, maintenance, and the warehouse can digitally communicate and collaborate to ensure spare parts are ready in time for an important project.

A connected worker can quickly onboard and receive in-context training information through mobile work instructions that walk them through the specific steps of a task. They have ready access to work orders, critical operational information, equipment location and status. They can quickly raise notifications when they see a safety hazard or identify equipment that needs additional maintenance, collaborating with distant colleagues to develop corrective actions.

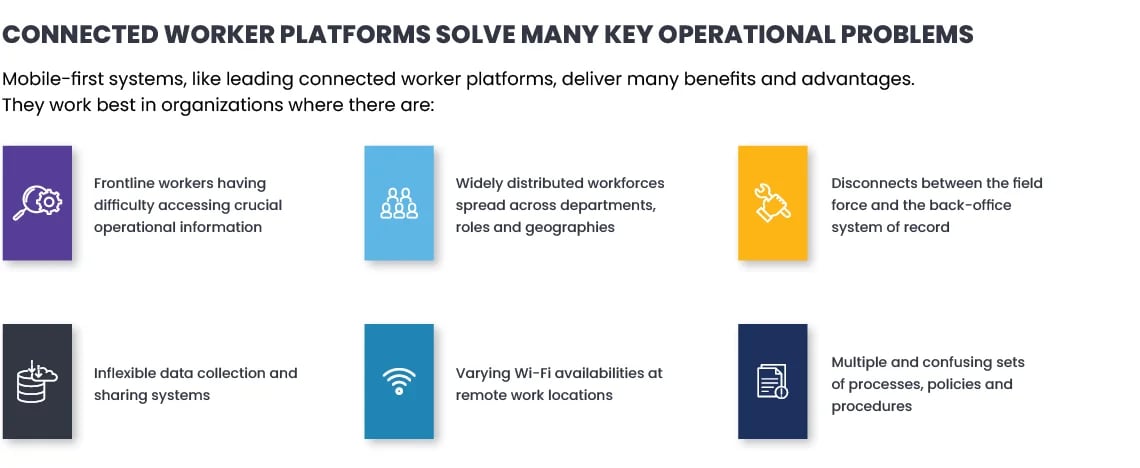

Productivity Problems Connected Worker Platforms Solve

Many manufacturing plants use inefficient and outdated processes to conduct operations. Primarily we’re talking about paper-based work order forms, inspections, checklists, inventory tally sheets, and supply requisitions.

Organizations using inefficient processes (like paper) have several bad attributes in common. For example, they:

- Lack of real-time visibility into daily operations

- Rely on manual data collection, entry, and sharing

- Have numerous information silos where data gets stranded

- Have difficulty making knowledge-based decisions

- Suffer low worker productivity and wrench time

- Pay more overtime than necessary to get work done

Manufacturers in this category frequently employ many repetitive and counterproductive tasks that require more work and effort rather than less. Many warehouse managers fret about how these four issues negatively impact worker productivity:

- Inventory control and tracking issues

- Low or no-value inventory data

- Transaction and processing errors

- Use of outdated technology

Adopting a digital solution, such as a connected worker platform, offers numerous benefits. Primarily, it reduces paper-based documentation, allowing frontline employees in the warehouse or the machinery plant to move freely with a mobile device in hand and remain productive. Managers and supervisors can follow the progress and receive updates in real-time from anywhere. Such capabilities empower proactive decision-making based on knowledge. It also enables companies to become nimbler in proactively addressing issues before they become production-stopping problems.

Connected Worker Platforms For Manufacturing

Connected worker platforms are solutions in manufacturing that connect human resources, machines, and data to increase productivity, optimize costs, and enhance safety. By offering real-time access to information and automating redundant tasks, cloud-powered platforms improve operational and overall manufacturing productivity.

The system also helps workers identify and correct any defects. Using online tools for detecting defects, manufacturers can significantly improve production quality and reduce wastage. Another advantage of connected worker platforms is that they help manufacturers improve safety within their facilities. Real-time alerts and notifications on any potential risk give ample time to take corrective action and avoid any incidents.

By automating work order and inspection processes, manufacturers can significantly reduce costs. Connected worker platforms offer several alternatives to manual processes to improve production quality and operations. By using modern technology and automation tools it provides ample opportunities to bring down production costs without compromising on quality.

Is a Connected Worker Platform Right For You? Find Out Today

Check out our recent ebook and case study about Innovapptive’s Connected Worker Platform to learn more about its capabilities. Then click here to arrange for a free no-obligation demonstration of our solution in action. Want to speak to one of our industry experts? They’re standing by to answer your questions now at 844-464-6668.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”