Industry 5.0: Ready For This Game-Changing Manufacturing Strategy?

The advent of Industry 5.0 is not just a milestone; it's a profound leap forward, heralding a new era in the manufacturing domain. With the fifth industrial revolution, we stand on the brink of a transformation that redefines how organizations operate across all sectors. The essence of Industry 5.0 is its focus on bringing humans to the forefront, bridging the gap between them and the interconnectivity of devices, platforms, and processes. This revolution is particularly pivotal for sectors like utilities, where the integration of advanced technologies offers unprecedented opportunities to enhance productivity, performance, and operational efficiency.

Understanding Industry 5.0 and Its Implications for Manufacturers

Industry 5.0 heralds a transformative era for the manufacturing industry, representing a significant shift towards a more collaborative and human-centric approach in industrial production. This evolution builds upon the technological foundations established by Industry 4.0, emphasizing the importance of synergy between humans and intelligent systems. Unlike its predecessor, which focused on automation and digitalization to improve efficiency, Industry 5.0 introduces a paradigm where technology serves to augment human capabilities, fostering an environment of co-creation and shared expertise between workers and machines.

The implications of this shift for the manufacturing sector are profound and multifaceted. Firstly, it paves the way for enhanced intuitive interactions between workers and interconnected devices, allowing for more nuanced control and optimization of production processes. This level of integration enables a seamless flow of information, making it possible to achieve unprecedented levels of operational efficiency and innovation.

Moreover, Industry 5.0 addresses the critical challenges facing the sector today, including the increasing pace of technological advancements, changing shareholder expectations, and the growing consumer demand for faster, more cost-effective, and personalized solutions. For utility companies and other industries, this transition offers a valuable opportunity to not only improve productivity and performance but also to meet these evolving market demands in a sustainable and socially responsible manner.

By prioritizing human creativity and problem-solving abilities alongside the use of advanced technologies such as AI, IoT, and robotics, Industry 5.0 encourages a culture of continuous improvement and innovation. This not only enhances the competitiveness of businesses but also contributes to creating more fulfilling and empowering work environments for employees. Ultimately, the integration of human intuition and machine intelligence under the umbrella of Industry 5.0 has the potential to redefine manufacturing processes, making them more adaptable, resilient, and aligned with the broader goals of environmental sustainability and social well-being.

Principles of Industrial Manufacturing Revolution 5.0

For Industry 5.0, a few core principles stand out, weaving a new narrative for manufacturing that's both futuristic and grounded in humanity. These aren't just buzzwords; they're the bedrock of a movement set to redefine what it means to produce, innovate, and sustain in the modern world.

Human-centricity: At the heart of Industry 5.0 lies human-centricity, a principle that aims to restore the human touch to our increasingly automated environments. This isn't about rolling back the clock on tech advancements. Far from it. It's about harmonizing these advancements with the unique insights, creativity, and adaptability that only humans can bring to the table. In practice, this means designing workflows and systems where machines handle the heavy lifting, leaving room for human workers to apply their skills in oversight, decision-making, and creative problem-solving. It's a collaborative dance between humans and machines, each playing to their strengths to achieve more together than they could apart.

Sustainability: Sustainability in Industry 5.0 is about more than just recycling or reducing waste—it's about embedding environmental consciousness into every aspect of the manufacturing process. From utilizing renewable energy sources to adopting materials and methods that minimize ecological impact, this principle is about ensuring that our drive for production doesn't come at the cost of the planet. By leveraging technologies like AI and IoT, manufacturers can predict and optimize their use of resources, drastically reducing their environmental footprint. It's a vision of manufacturing that not only meets today's needs but preserves the possibility of a healthy, thriving world for generations to come.

Customization: The move towards customization in Industry 5.0 reflects a growing demand for products that meet specific customer needs and preferences. Gone are the days of one-size-fits-all manufacturing. In its place, we're seeing the rise of systems capable of producing highly personalized items without sacrificing efficiency or scalability. This principle leverages the power of digital fabrication technologies, such as 3D printing and CNC machining, allowing for on-the-fly adjustments to product design to suit individual specifications. It's a game-changer for both producers and consumers, offering a level of personalization and flexibility that was previously unthinkable.

Resilience: Lastly, resilience in Industry 5.0 is about creating systems that are not just efficient and productive but also robust and adaptable. In an era marked by rapid change and unforeseen challenges—from global pandemics to supply chain disruptions—manufacturing systems need to be designed with flexibility and recovery in mind. This means implementing smart networks that can respond dynamically to changes, whether they're adjusting to fluctuations in demand or pivoting in the face of raw material shortages. It's about ensuring that the manufacturing sector isn't just surviving but thriving, regardless of what the world throws its way.

Together, these principles paint a picture of Industry 5.0 as a revolution that's not just technological but profoundly human and ecological. It's a vision of manufacturing that's innovative, sustainable, personalized, and resilient—a stark contrast to the one-size-fits-all, efficiency-at-all-costs mentality that has dominated the industry in the past.

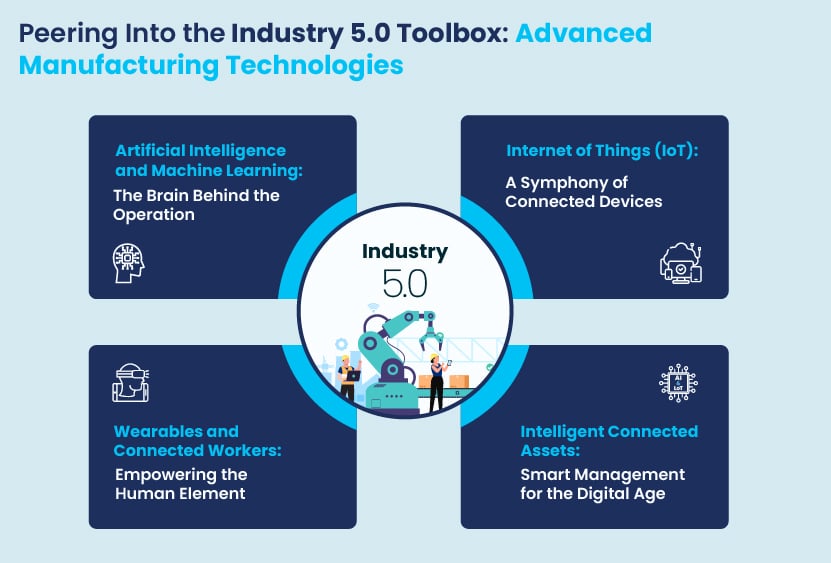

Peering Into the Industry 5.0 Toolbox: Advanced Manufacturing Technologies

In the unfolding narrative of Industry 5.0, the spotlight often falls on the dazzling array of technologies that make this new era possible. These aren't just incremental upgrades to our industrial toolkit; they're transformative forces that redefine the boundaries of what's possible in manufacturing. Let's delve deeper into these technological marvels, painting a picture of a future where efficiency meets innovation in unprecedented ways.

Artificial Intelligence and Machine Learning: The Brain Behind the Operation: At the forefront of Industry 5.0's technological vanguard are Artificial Intelligence (AI) and Machine Learning (ML). Think of these not just as tools but as the central nervous system of the modern manufacturing floor, driving smarter, more predictive analytics and decision-making processes. AI and ML sift through mountains of data in real-time, spotting trends, predicting maintenance needs before they become issues, and optimizing production lines for efficiency without human intervention. This capability transforms manufacturing from a reactive to a proactive endeavor, where decisions are informed by foresight rather than hindsight.

Internet of Things (IoT): A Symphony of Connected Devices: The Internet of Things (IoT) brings a level of interconnectivity to manufacturing that was once the stuff of science fiction. Imagine every device, machine, and sensor on the factory floor connected in a harmonious digital ecosystem, exchanging data in real-time. This networked dialogue allows for an unprecedented level of coordination and optimization, enabling manufacturers to adjust operations on the fly based on immediate data insights. The result? A manufacturing process that's not just faster and more efficient but also more adaptable to the ever-changing demands of the market.

Wearables and Connected Workers: Empowering the Human Element: In an Industry 5.0 world, wearables and connected worker technologies are about enhancing the human factor, not replacing it. These digital tools—ranging from smart glasses to wearable sensors—transform field workers into cyborg-like entities, endowed with instant access to information, guidance, and support. This not only boosts productivity but also significantly enhances safety, allowing workers to receive real-time alerts about potential hazards or inefficiencies. It's a fusion of human intuition and digital intelligence, empowering workers in ways that elevate the entire manufacturing process.

Intelligent Connected Assets: Smart Management for the Digital Age: Finally, the concept of intelligent connected assets marries the prowess of AI and IoT to revolutionize asset management and maintenance. Imagine machines that can predict their own maintenance needs, schedule their own downtime, and even order parts for repairs without human intervention. This self-regulating approach to asset management not only reduces downtime but also extends the lifespan of machinery, ensuring that every piece of equipment operates at peak efficiency throughout its lifecycle.

Together, these technologies form the backbone of Industry 5.0, ushering in a new era of manufacturing that's smarter, more connected, and more human-centric than ever before. It's a world where technology amplifies human potential, machines communicate to optimize their operation, and the entire manufacturing process becomes a seamless blend of digital and physical realities.

The Far-reaching Benefits of Industry 5.0 for Manufacturing

As we venture deeper into the realms of Industry 5.0, it's clear this isn't just an evolution in technology—it's a revolution in how manufacturing can and will operate. This transformative wave brings with it a plethora of benefits that extend far beyond the factory floor, heralding a new age of efficiency, safety, and customization that was once deemed unattainable. Let's unpack these advantages, each a testament to the pioneering spirit of Industry 5.0.

Supercharging Productivity: One of the most immediate benefits of embracing Industry 5.0 is the significant uptick in productivity. This isn't productivity for its own sake but a smarter, more humane approach to getting things done. Through the advent of connected workers, equipped with wearables and IoT devices, every movement and action becomes more efficient. These technologies provide workers with real-time data and insights, allowing them to make informed decisions swiftly, reduce downtime, and streamline processes like never before. It's akin to orchestrating a symphony, where every instrument and note is in perfect harmony, achieving a level of operational rhythm and productivity that sets new benchmarks.

Elevating Safety and Compliance: Industry 5.0 also marks a significant leap forward in workplace safety and regulatory compliance. With the integration of real-time monitoring systems and predictive analytics, potential hazards can be identified and mitigated before they pose a risk to workers. This proactive approach to safety, underpinned by AI and machine learning, doesn't just protect the workforce—it fosters a culture of vigilance and care that permeates every aspect of manufacturing. Compliance with regulatory standards becomes a byproduct of this heightened safety ecosystem, ensuring manufacturers not only meet but exceed the necessary guidelines and practices.

Refining Operational Efficiency: The synergy between front-line workers and back-office systems in Industry 5.0 is nothing short of revolutionary. By harnessing the power of intelligent connected assets and sophisticated data analytics, manufacturers can achieve a level of operational efficiency that seamlessly bridges the gap between the tangible and digital realms. This integration ensures that decision-makers have access to actionable insights in real time, enabling a swift response to production challenges, supply chain hiccups, or customer demands. It's a dance of efficiency, where each step is measured, coordinated, and executed with precision, ensuring the machinery of production moves as one cohesive unit.

Unleashing Customization and Flexibility: Perhaps one of the most consumer-facing benefits of Industry 5.0 is its ability to unlock unparalleled levels of customization and flexibility in manufacturing. This principle empowers manufacturers to cater to specific customer demands with agility and precision, offering personalized products without the traditional costs or delays associated with bespoke manufacturing. Digital fabrication technologies, such as 3D printing, alongside AI-driven design tools, allow for rapid prototyping and customization at scale. This capability not only enhances customer satisfaction but also opens new markets and opportunities for manufacturers willing to embrace the unique demands of the modern consumer.

Achieving Higher Productivity, Safety, and Performance with Connected Workers

The concept of the Connected Worker epitomizes the spirit of Industry 5.0. By digitally connecting front-line workers, organizations can simplify complex tasks, enhancing efficiency and productivity. Platforms like Innovapptive's Connected Workforce Platform exemplify this approach, seamlessly integrating field workforce with back-office operations to optimize workflows and maximize operational excellence. Such platforms not only facilitate better decision-making through real-time data access but also ensure that workers have what they need, when and where they need it, thereby driving higher customer satisfaction and revenue.

Time to Change Your Game – Learn How Innovapptive Can Help

Innovapptive stands tall in the Connected Worker marketplace. We’re one of the pioneers in using mobile-first, connected worker technology to digitally transform manufacturing operations, maintenance, and warehouse. Discover how our solutions can empower your company and its workforce to take full advantage of the benefits described in this blog. The first step? Schedule your free, no-obligation demo of our solution in action. Our experts will show you how our applications can be tailored your unique situation and answer any questions you may have. Don’t wait. Your future starts today!

FAQs

Why is Industry 5.0 so significant?

Industry 5.0 represents a crucial step forward in aligning business operations with societal needs and environmental goals. It enables industries to actively contribute solutions for resource preservation, social stability, and climate challenges. By focusing on the broader implications of business operations, including employee well-being and ecological sustainability, Industry 5.0 positions connected businesses as key players in solving global challenges, moving beyond mere productivity and profit.

What does Industry 5.0 bring to the manufacturing table?

Industry 5.0 is set to revolutionize manufacturing by enhancing automation processes with real-time data analytics, while also emphasizing the synergy between human workers and machinery. This combination aims to not only streamline operations but also inject a level of personalization in production that meets the unique needs of customers.

How does Industry 5.0 address the issue of customization in manufacturing?

Industry 5.0 leverages AI, IoT, and connected worker technologies to offer more flexible and adaptable manufacturing processes. This enables manufacturers to easily tailor their products and services to meet specific customer requirements, thus enhancing satisfaction and loyalty.

What are the challenges associated with implementing Industry 5.0 in manufacturing?

Challenges include the need for substantial investment in new technologies, the requirement for workforce re-skilling, and overcoming resistance to change. Additionally, achieving a seamless integration between various digital tools and platforms presents a significant hurdle.

How does Industry 5.0 differentiate from its predecessors?

Industry 5.0 marks a distinct shift toward leveraging modern technology to foster a collaborative work environment between humans and machines. Unlike previous revolutions, which were primarily technology-driven, the fifth revolution emphasizes a human-centric approach, aiming for a resilient, sustainable future that's aware of environmental concerns.

What distinguishes Industry 5.0 from Industry 4.0?

While Industry 4.0 focused on automation and technology to enhance productivity, Industry 5.0 is value-driven, seeking to reintegrate humanity into the manufacturing process. It champions systems and processes designed to benefit not only the business but also the employees, society, and the environment.

How does the future of Industry 5.0 look?

Industry 5.0's future is bright, marked by the advent of robots equipped with enhanced AI and cognitive computing capabilities. These advancements are expected to boost efficiencies and speed up delivery times, all while allowing human workers to dedicate their focus to more nuanced tasks and creative pursuits.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”