Leveraging Electronic Proof of Delivery (ePod) in the Supply Chain to reduce Working Capital and to deliver the Perfect Order

Your Supply Chain is humming……. the customer order has been captured correctly, all required stock is available, the right quantity/product is picked, the vehicle is loaded and left spot on time. Your well on the way to deliver your customer the Perfect Order. What could possibly go wrong? At this point savvy transport managers may well be grimacing, as they know that you’re still a long way from the goal of the Perfect Order. Traffic congestion, the driver picking the wrong products from the vehicle or losing the Proof of Delivery can all frustrate achieving the Perfect Order. Its critical to get this last link in the Supply Chain, the “final mile” right if you’re going to delight your customers.

One of the challenges of the “final mile” is that the business processes are often paper based. After the vehicle is loaded at the warehouse the driver receives a heap of paper Delivery Notes and a Summary Manifest. The Delivery Note contains the delivery address and details of products/quantities ordered by the customer. If its multi-drop distribution with 30 deliveries, that’s quite a wad of paper! When the driver arrives at the customer’s premises and off-loads the product then he needs a customer signature on the Delivery Note to confirm what was delivered. Once the customer has signed the Delivery Note it becomes a Proof of Delivery (POD) and shows that legal ownership has changed from the supplier to the customer. In many organisations the POD also becomes the basis for invoicing the customer, ensuring the customer gets invoiced for the right products/quantities. However, before the invoice can be generated the POD needs to get back to the office for products/quantities to be confirmed in the ERP system. As transport managers know, it can take several days for the POD to get back to the office, PODs can get lost and finally office staff need to interpret what has been written on the POD. Drivers like doctors are not known for their handwriting skills!

You can start to see that the humble POD can have a big impact on your business. If the POD takes 3 days to get back to the office that’s a hit to your working capital because payment terms usually start on the date the invoice is created. If the driver made an adjustment to the Delivery Note, for example, 8 cases were returned damaged, but the office staff thought the 8 was a 3, then you end up sending an incorrect invoice, you have over-charged the customer and they are not happy. If the POD got lost, then there is danger you don’t invoice the customer at all. Another important function of the POD is to capture the correct date and time of delivery. On-time delivery is an important component of the Perfect Order and customers often track this as part of their own regular supplier appraisals. But if your loosing PODs or drivers are not completing them properly your visibility into On-Time delivery performance is lost.

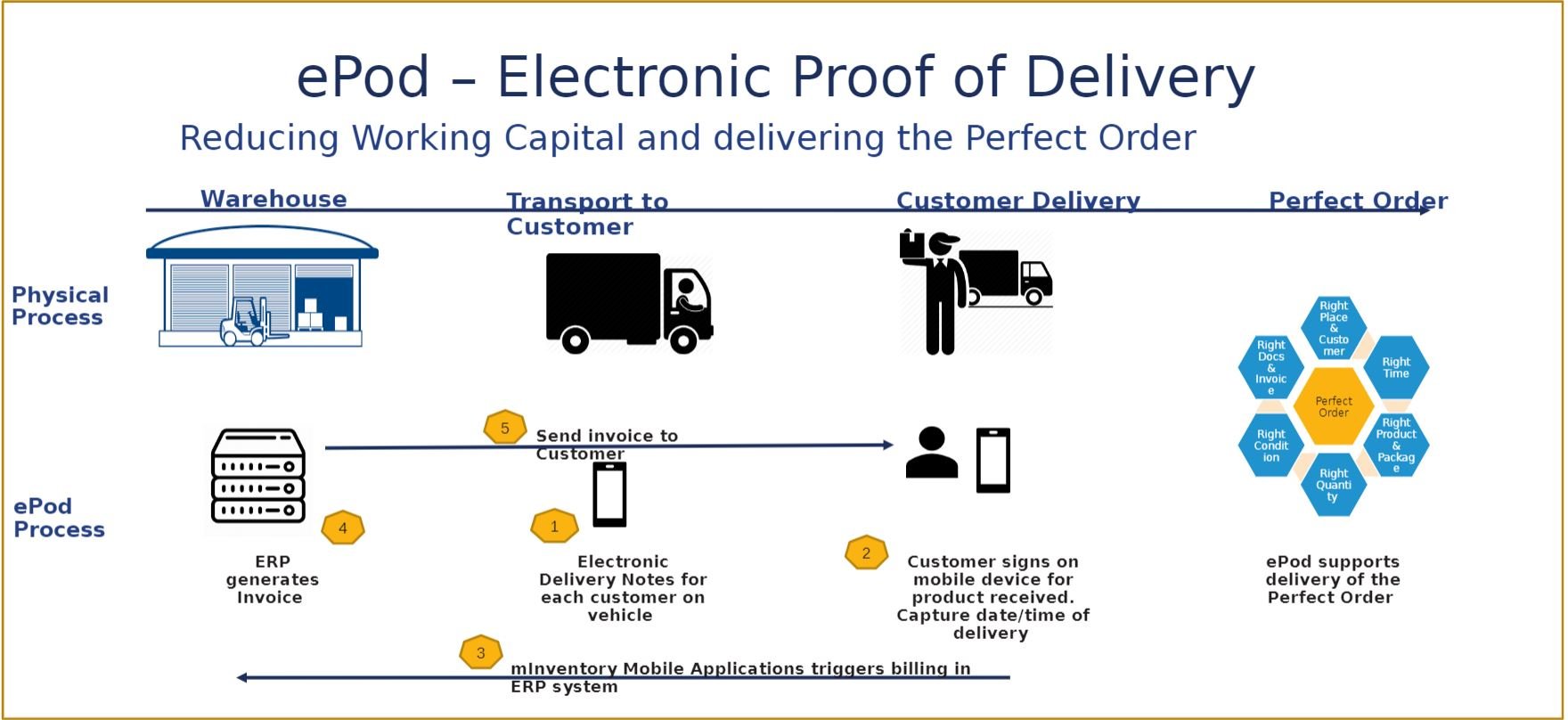

However, we have some good news for our transport managers, there is a simple solution available to the POD problem. The whole delivery and POD process can be operated on a mobile application on a smart phone, such as, Innovapptive’s mInventory, the diagram below shows how an electronic Proof of Delivery (ePod) process works.

When the driver arrives at the customer premises, he checks off products against the electronic Delivery Note on mInventory and confirms the date/time of delivery. The customer then signs on the smart phone to confirm receipt of the delivery. At this point the back-end ERP system is immediately updated and the billing process is triggered. The Customer can be emailed the POD or if they really need a paper copy, it can be printed on the driver’s mobile printer. This ePod process makes sure your customer gets invoiced more quickly and accurately. A 3-day reduction in time to invoice customers can translate to a multi-million improvement in working capital for a high-volume manufacturer. Additionally, On-Time performance is captured electronically ensuring this important measure of Supply Chain performance is accurate.

Having ePOD available on all mobile devices is a simple solution to your “final mile” challenges and can help ensure you deliver the Perfect Order every time.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”