Managing the Complexities of Decentralized Inventory With Mobile Inventory Management

Should you operate a single centralized warehouse or smaller satellite facilities? Centralized inventory management is cost efficient. Decentralized inventory management places items closer to demand. This blog shows how a mobile inventory management solution maximizes the benefits of each.

Conventionally, the “right” number of warehouses to serve the market becomes a trade-off between warehouse costs and transport costs, but critically customer service needs to be considered. If it takes three days to process and deliver an order from the central warehouse to the customer but the customer needs delivery in two days then a single central warehouse will be insufficient. Decentralized inventory in such cases proves to be more cost-effective in the long run.

Centralized vs. Decentralized Inventory Debate

The debate between centralized and decentralized inventory is as old as Supply Chain Management. It focuses on the pros/cons of holding inventory in one large, central warehouse (centralized inventory) versus multiple smaller warehouses (decentralized inventory). Typically, cost modeling will show a central warehouse reduces overall inventory levels, working capital costs, and warehouse costs versus decentralized warehouses. However, a centralized model leads to higher transport costs because of the greater distance to the customer base.

A shift to a decentralized warehouse takes the items closer to the location of actual demand bringing agility to the supply chain system. Each of the warehouses in the decentralized inventory network caters to location-specific demands. This reduces the burden of overstocking every item. The inventory is demand-based, and stocks are maintained at optimum levels accordingly. For any critical MRO requirement, the time for spare parts to reach the location is drastically reduced. The company even saves on the cost of transportation since the item is to be delivered nearby.

Decentralized inventory helps in managing last-mile demand and just-in-time inventory management. It eliminates the need for overstock inventory to cater to sudden demand spikes and saves money from being stuck in dead inventory.

Managing the Complexities of Decentralized Inventory

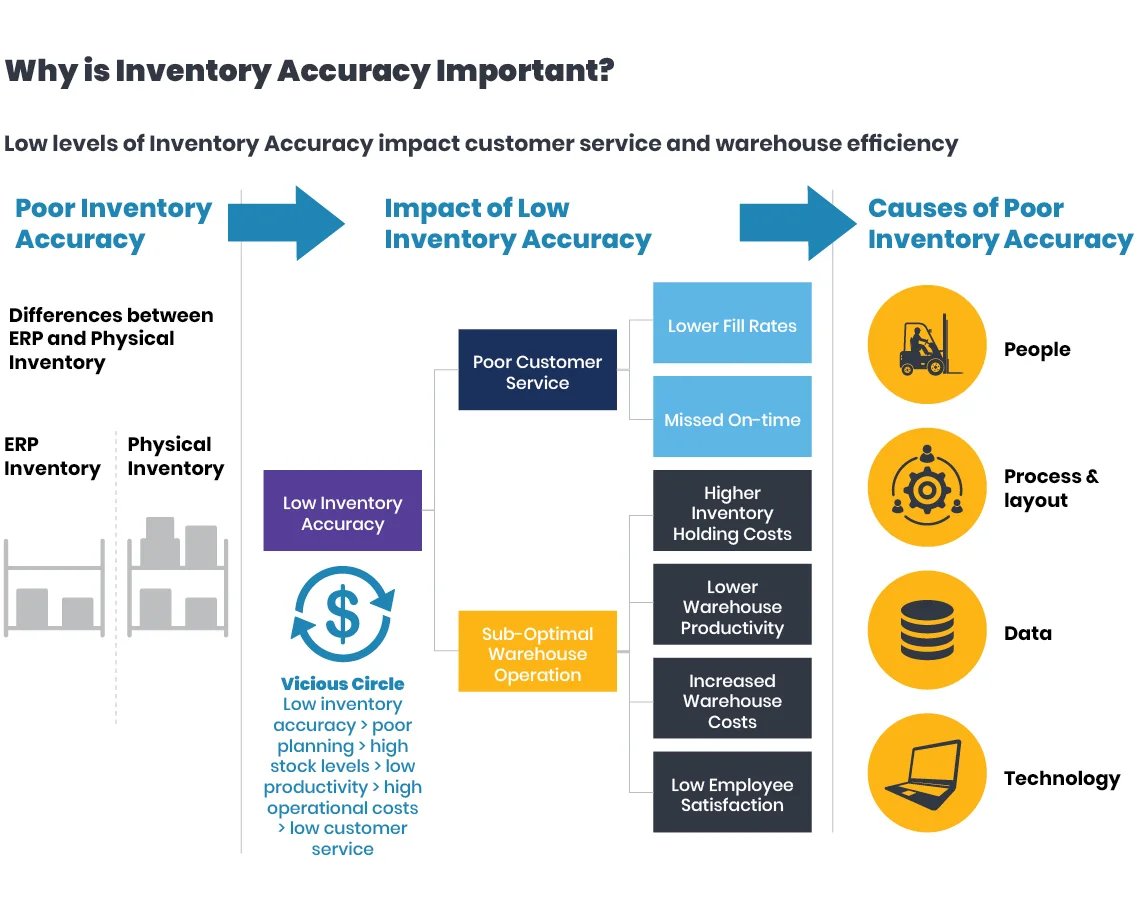

A critical consequence of decentralized inventory is increased supply chain complexity. New inventory holding locations, from vans to lockers, need to be managed to ensure customer service requirements are achieved. Using the Enterprise Resource Planning (ERP) system, inventory replenishment, and inventory accuracy are a few important factors for consideration while managing these complexities.

Companies have sometimes taken a short-term view of these smaller inventory locations and attempted to manage them outside the system. This can lead to poor inventory controls and a negative impact on customer service. Investment in an ERP system to automate the key business processes is worthwhile in such cases.

The ERP system can then be used to manage inventory replenishment to these new stock holding locations. They are physically smaller than traditional warehouses and hold less inventory buffer, which puts the onus on a robust replenishment process based on high inventory accuracy.

A third area that needs focus is the complete inventory control process at each location. It’s crucial to capture accurate receipts of products and issues to maintain inventory accuracy and high levels of customer service.

Connected Inventory Management System as a Solution

Companies need a tightly knit supply chain ecosystem to gain maximum return on investment from a decentralized warehouse strategy. A connected inventory management system can solve the challenges of managing a dispersed network to keep communication and collaboration on par with dynamic demands. The solution must focus on enhancing warehousing processes through automated workflows and provide a digital infrastructure to offer access to required real-time information/data to all the stakeholders.

Innovapptive’s connected mobile inventory management solution – mInventory – offers the right choice for optimizing and managing your decentralized inventory. mInventory delivers agility, flexibility, and seamless integration between your core inventory processes and back office systems.

mInventory connects warehouse operations and SAP and IBM Maximo in real-time, eliminating delays between the physical movement of inventory and its recording in the back-office system, leading to greater stock accuracy and visibility, lower costs, and knowledgeable, data-driven decisions.

To improve your stock transfers for measurable gains with mInventory, schedule a free demo today by calling 844-464-6668 or watch a video here.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”