Mobile Warehouse Management Benefits for Building Materials Distributors

With construction season nearly upon us, it’s prime season for homebuilders and commercial construction contractors. Warmer weather and longer daylight hours are ideal for making rapid progress on new homes, apartment complexes, shopping centers, and office buildings. One potential snag is ready access to building and construction materials. Lack of materials will bring a project to a sudden halt that can be expensive for both the construction company and the client. Can a mobile warehouse management solution help building material distributors keep construction companies well-stocked while improving their operational efficiency and productivity?

Building Material Distributors Still Using Inefficient Warehouse Management Processes

Despite being almost a quarter into the 21st century, too many building materials warehouses employ an outdated 20th-century method of goods receipt, putaway, inventory, picking and packing, kitting, and goods issue. That is, they use a paper-based process. This situation means every transaction is recorded on a slip of paper that then has to be entered into a back-office system (like SAP).

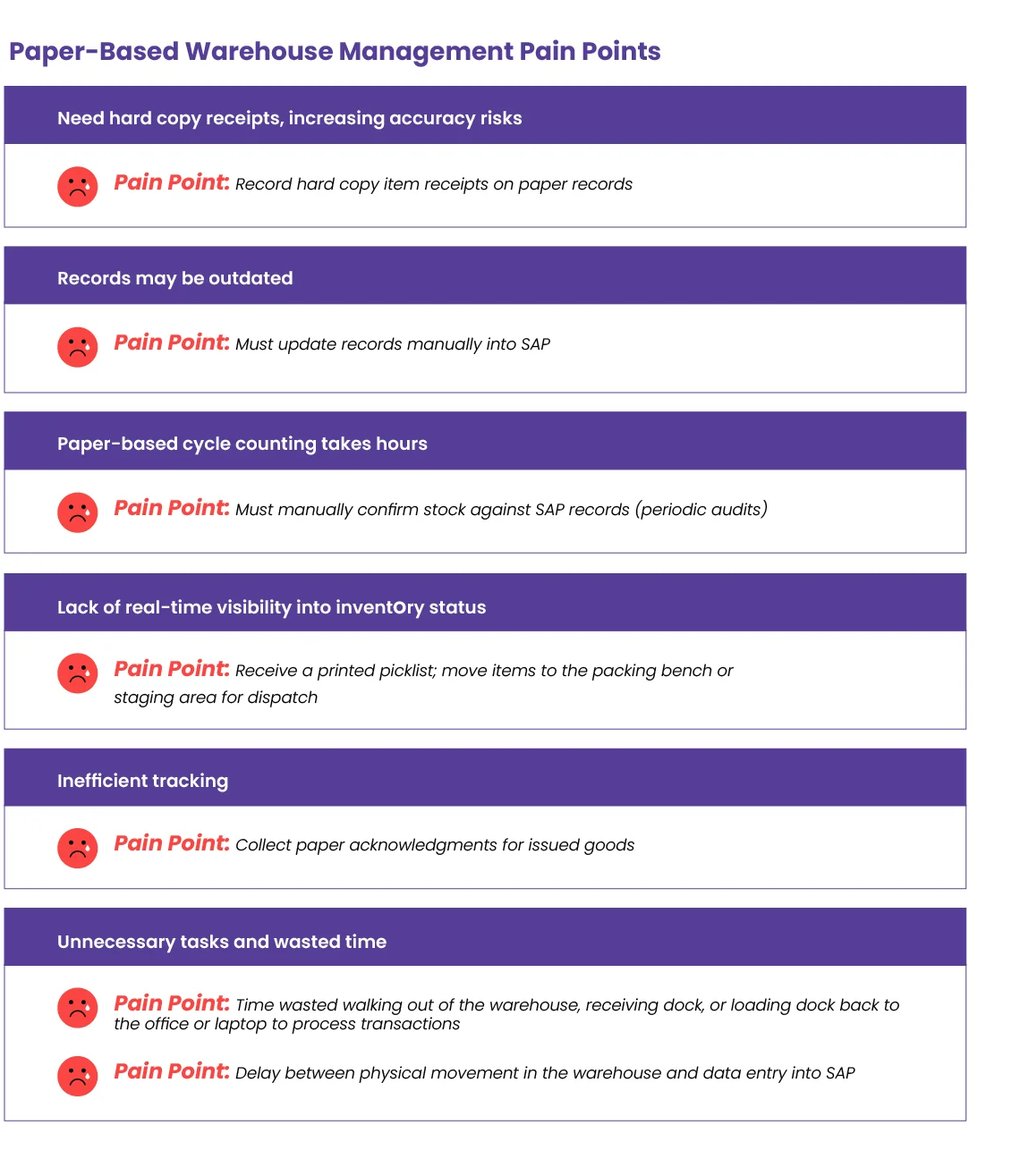

For starters, this is an inefficient system that leads to several troublesome issues and problems. Traditional paper-based warehouse processes lead to several inefficiencies, including:

- Limited Visibility: Manual inventory tracking hinders real-time stock levels, potentially leading to stockouts and delayed deliveries.

- Increased Errors: Paperwork is prone to human error, resulting in inaccurate data and discrepancies during inventory audits.

- Inefficient Processes: Manual workflows slow down receiving, picking, and packing activities, impacting overall warehouse productivity.

- Poor Communication: Lack of seamless communication between teams creates data inconsistencies and hinders informed decision-making.

Problems and pain points like those above can lead to lower frontline worker productivity, more frequent overstocks or understocks, and higher inventory carrying costs. Worse, they could slow or prevent a building materials distributor from getting needed supplies to customers in the field, jeopardizing relationships and revenues. Is there a solution to help these outfits overcome these challenges? Happily, that answer is an emphatic yes.

mInventory: A Mobile Warehouse Management Solution for Building Materials Distributors

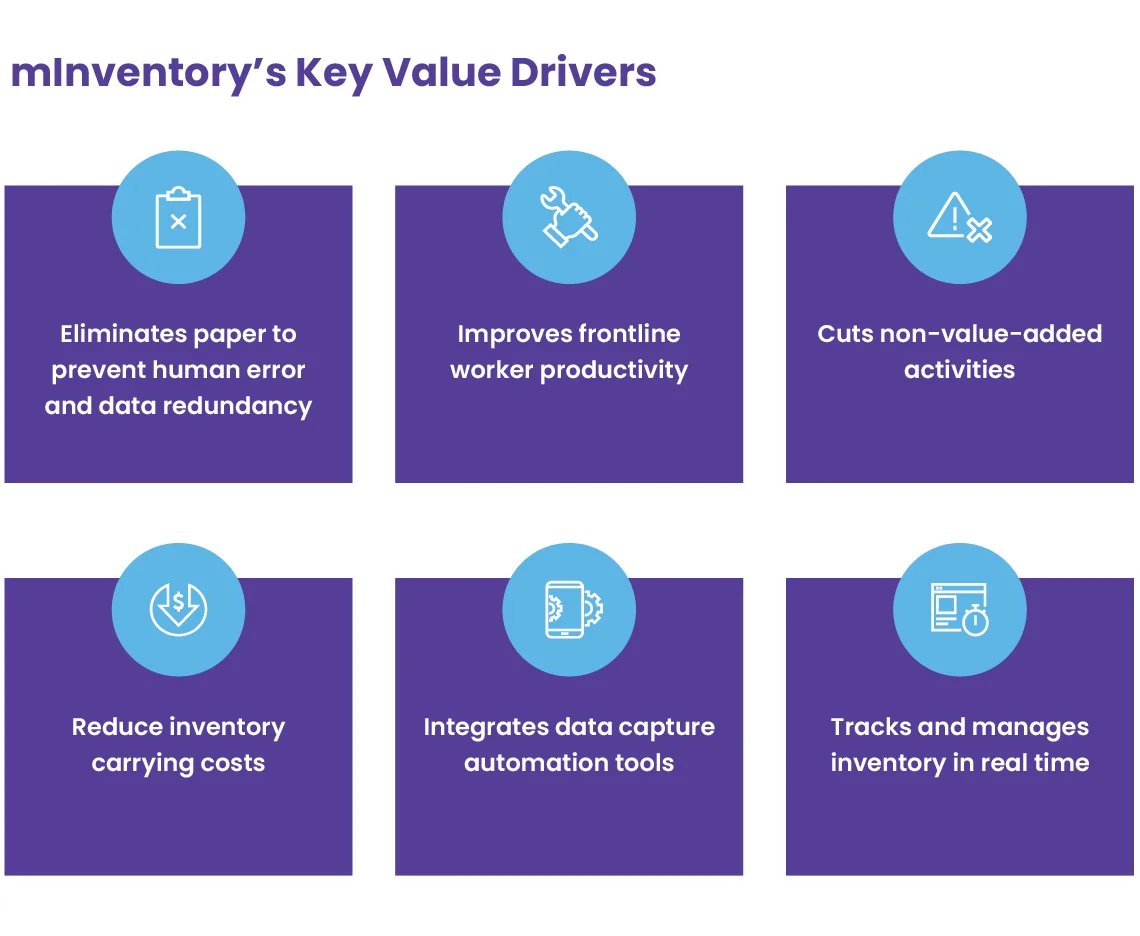

Innovapptive is a worldwide digital transformation leader. It’s our mission to connect and create conversations between people, machinery, and work processes to improve people’s lives. To that end, we’ve developed a mobile-first warehouse management solution that eliminates paper-based processes, increases accuracy, boosts frontline worker productivity, and reduces inventory carrying costs.

mInventory leverages barcode scanning technology and real-time data capture to streamline warehouse operations. This empowers building material distributors to:

- Enhance Inventory Accuracy: Real-time data eliminates errors associated with manual counting and ensures accurate stock levels.

- Boost Warehouse Efficiency: Automated workflows and mobile access expedite receiving, picking, and packing tasks, increasing worker productivity.

- Improve Decision Making: Data-driven insights from mInventory provide valuable information for informed inventory management strategies.

- Optimize Supply Chain Visibility: Real-time inventory tracking empowers better forecasting and ensures timely deliveries to construction sites.

Gone are the cumbersome paper forms, tally sheets, and tickets that lead to frustrated employees, missing information, and incorrect counts. Instead, workers use a digital process to count, with continuously updated totals. This capability delivers accurate, verified data to key stakeholders, enabling them to make more informed, knowledgeable warehouse management decisions in real time.

Goods Receipt and Goods Issue represent two critical warehouse functions. mInventory automates and simplifies these vital tasks. Now, warehouse clerks can receive goods and process them without touching or filling out paper forms. They can immediately scan the incoming items and enter information into the back-office system via the good’s barcoded label. Or, if the incoming goods lack barcodes, mInventory can use Optical Character Recognition (OCR) technology to scan whatever comes with the item to create a label at the point of application and a record in the back-office system. Goods Issue aligns in real time with SAP to identify and track items. Since frontline workers enter all information, tasks take less time and are without the errors found in paper-based forms and data entry.

With mInventory building materials warehouse managers and frontline workers can:

- Replace paper-based cycle count sheets, pick tickets, and scratch pads with a customizable, real-time digital solution

- Scan 1D or 2D and QR codes to ship and receive inventory using any handheld devices, including mobile phones, tablets, and external peripherals

- Conduct inbound/outbound transactions

- Perform goods receipts, goods issues, and transfer posting

- Track stock movement with precision across plants, storage locations, trucks, and bins

- View inventory and warehouse stock levels

- Carry out cycle counts, including blind counting from the warehouse floor

- Improve real-time communication between workers in the warehouse, senior management, and back-office enterprise resource planning (ERP) software

What can users expect from mInventory? Innovapptive clients have reported the following best-case scenarios:

- Up to a 50% decrease in cycle count time

- Up to a 98% improvement in inventory accuracy

- Up to a 5% drop in inventory carrying costs

Innovapptive can help improve your warehouse management process, just like we did for this building materials distributor in our latest case study: Building Materials Distributor Enjoys Greater Warehouse Efficiency.

Ready to Learn More about mInventory? Here’s How

Schedule a free demo of mInventory today, then call us at 888-464-6668. Our experts can show you how a mobile warehouse management solution can improve your process, accuracy, and productivity.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”