Shift Handovers Past Incidents: How Digitization Could Have Solved These Problems

Key Takeaways

- Critical Failures in Shift Handover: Historical industrial incidents underscore the deadly consequences of poor shift handovers.

- Potential for Digitization: Digital shift handover solutions could have mitigated these incidents by ensuring accurate and consistent communication.

- Digital Shift Handover: Digital solutions provide comprehensive tools to streamline communication, reduce human error, and improve safety.

Introduction

Shift handover is a crucial process in industrial operations where responsibility for ongoing tasks, safety protocols, and operational conditions are transferred from one shift to the next. When this process fails, the consequences can be catastrophic, as demonstrated by numerous historical incidents. This blog explores ten significant industrial accidents where poor shift handover played a critical role and how digitization could have prevented these tragedies. With the advancement of digital tools, companies like Innovapptive are leading the charge in modernizing shift handover processes to ensure safety, compliance, and operational efficiency.

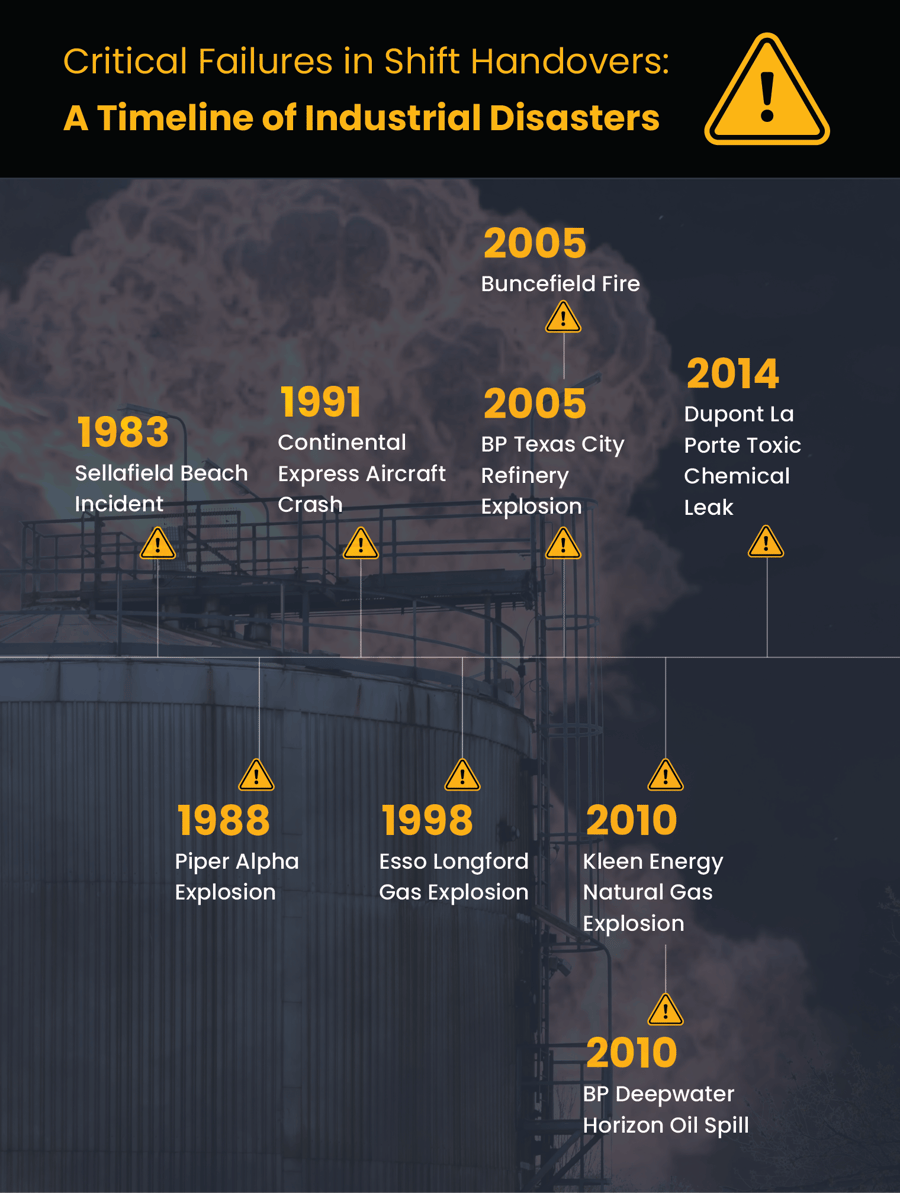

A Look Back at Major Incidents

1. 1983 Sellafield Beach Incident

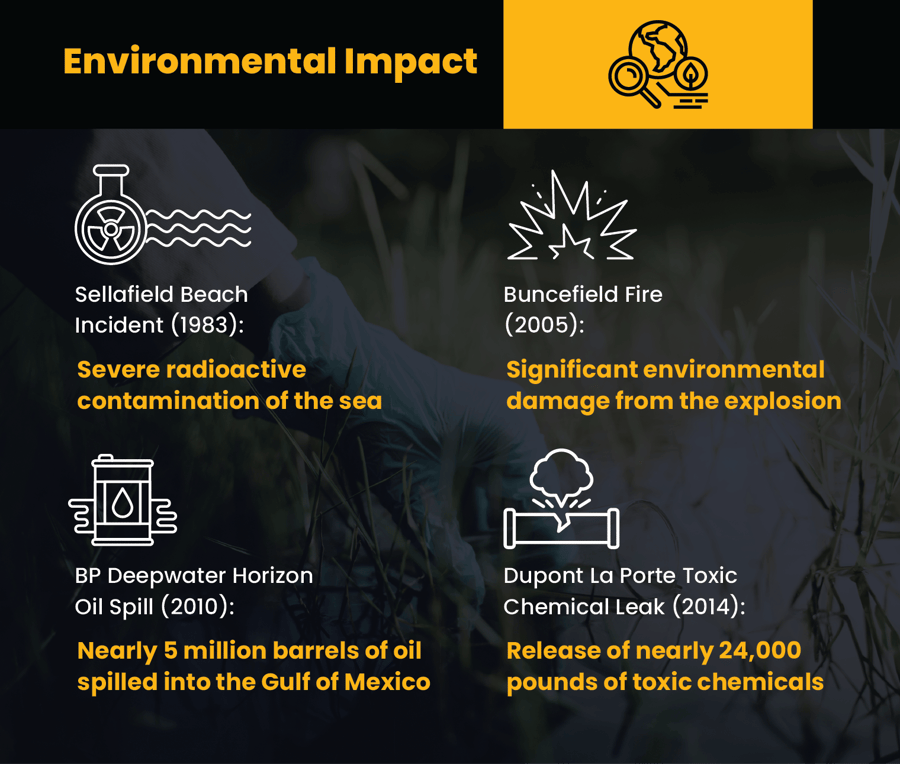

The Sellafield Beach incident was a significant environmental disaster where highly radioactive waste was accidentally discharged into the sea due to a failure in communication between shifts. The incident was exacerbated by transcription errors in the written logbook, which led to a misunderstanding of the tank’s contents. This resulted in a serious contamination of the nearby beach, requiring extensive clean-up efforts. The mishandling of this incident highlighted severe deficiencies in the communication protocols at the nuclear reprocessing plant, leading to public outcry and regulatory scrutiny over nuclear safety practices (Wikipedia).

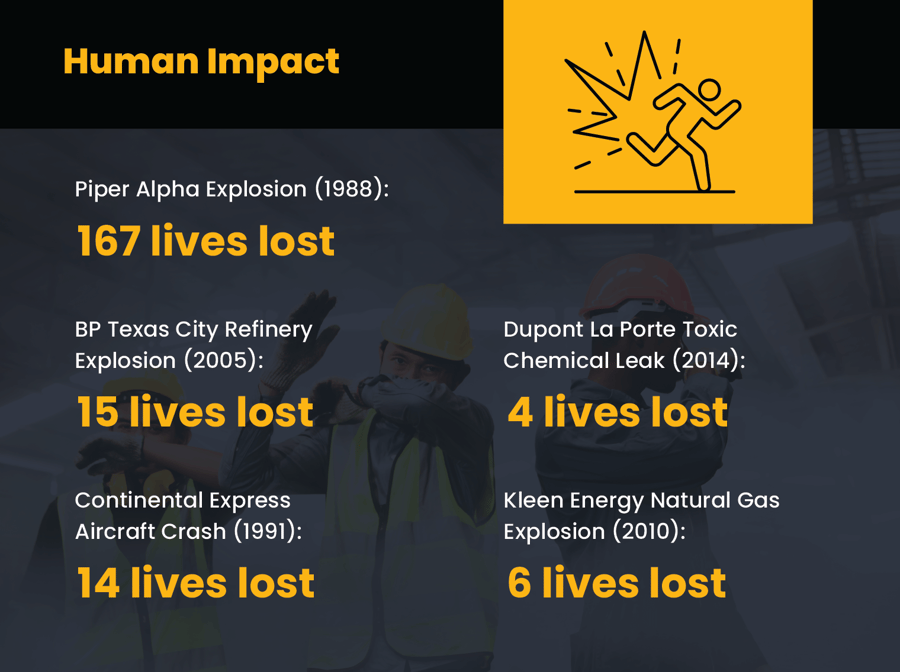

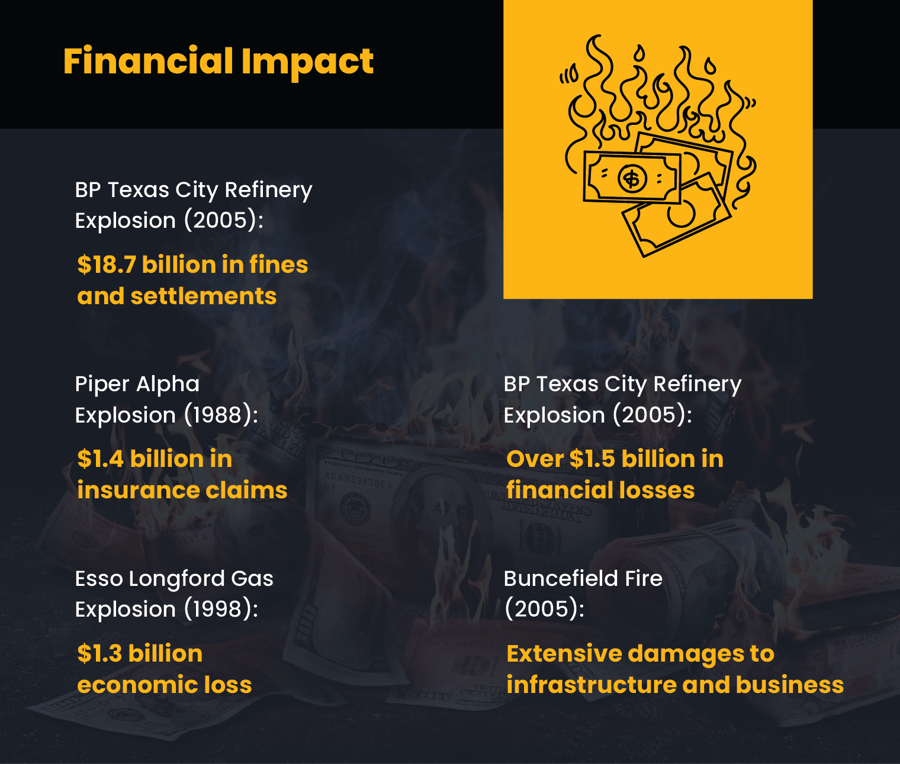

2. 1988 Occidental Piper Alpha Explosion

The Piper Alpha disaster remains the worst offshore oil disaster in history, claiming 167 lives. The explosion was triggered by a failure in the transmission of critical information during the shift handover. Specifically, a pressure safety valve was replaced with a blank flange, and crucial instructions not to use the equipment were not communicated to the incoming shift. This oversight led to a massive gas leak, which ignited and caused a series of explosions. The incident resulted in over $1.4 billion in insurance claims, and it profoundly changed safety regulations in the offshore oil industry (Wikipedia).

3. 1991 Continental Express Aircraft Crash

On September 11, 1991, Continental Express Flight 2574 crashed near Eagle Lake, Texas, killing all 14 people on board. The National Transportation Safety Board (NTSB) investigation revealed that the accident was caused by a failure during the maintenance shift handover. A row of fasteners for the aircraft's left horizontal stabilizer was removed but not replaced during routine maintenance, and this critical information was not conveyed to the incoming maintenance crew. This lapse in communication resulted in the structural failure of the stabilizer during flight, leading to the tragic crash (Wikipedia).

4. 1998 Esso Longford Gas Explosion

The Esso Longford gas explosion occurred on September 25, 1998, and claimed the lives of two workers while injuring eight others. The explosion was attributed to a breakdown in communication during shift handovers. Critical information about the unstable state of a heat exchanger was not properly documented or communicated, leading to a catastrophic rupture. The incident halted gas supplies to the state of Victoria for two weeks, resulting in a loss of $1.3 billion to the Australian economy. The Royal Commission that followed criticized Esso's failure to ensure effective communication and safety procedures (Wikipedia).

5. 2005 BP Texas City Refinery Explosion

On March 23, 2005, the BP Texas City Refinery experienced a series of explosions that killed 15 workers and injured more than 180. The incident was caused by poor communication during the shift handover, where critical information about the startup procedure of an isomerization unit was not properly conveyed. The lack of clear communication and a failure to follow operational protocols led to the overfilling of a splitter tower, which resulted in a massive vapor cloud that ignited. The disaster led to over $1.5 billion in financial losses and marked one of the deadliest industrial accidents in U.S. history (Wikipedia).

6. 2005 Buncefield Fire

The Buncefield fire, which erupted on December 11, 2005, at a fuel storage facility in the UK, was one of the largest explosions ever recorded in Europe. The disaster was triggered by a series of errors during the night shift handover, where operators failed to communicate critical information about the tank filling operations. The automated tank gauging system failed to alert operators that a tank was overfilling, leading to a massive explosion that destroyed the facility, injured 43 people, and caused significant environmental damage. The incident underscored the need for stringent communication protocols in hazardous operations (Wikipedia).

7. 2010 Kleen Energy Natural Gas Explosion

On February 7, 2010, the Kleen Energy power plant in Connecticut was rocked by a massive explosion that killed six workers and injured at least 50 others. The U.S. Chemical Safety Board’s investigation revealed that the explosion was caused by poor communication during the shift handover. Workers were not adequately informed about the planned natural gas blows, which were intended to clean out piping. The lack of clear communication led to the inadvertent ignition of the gas, resulting in one of the most devastating industrial explosions in recent U.S. history (Wikipedia).

8. 2010 BP Deepwater Horizon Oil Spill

The Deepwater Horizon oil spill began on April 20, 2010, when an explosion on the oil rig led to the release of nearly five million barrels of oil into the Gulf of Mexico over 87 days. The disaster, which resulted in the deaths of 11 workers, was significantly exacerbated by poor communication during the shift handover. Critical information about the well's integrity was not adequately communicated, leading to decisions that triggered the blowout. The spill had devastating environmental and economic impacts, with BP ultimately agreeing to pay $18.7 billion in fines and settlements (US EPA, Wikipedia).

9. 2013 KiwiRail Train Derailment

On May 20, 2013, a Wellington-bound train derailed in New Zealand, injuring four passengers. The derailment was attributed to maintenance errors during an overnight shift change. Ten weeks prior, maintenance staff had failed to fit critical split pins to bolts, a task that was not recorded or communicated to the incoming shift. The omission of this critical maintenance task led to the derailment, underscoring the importance of detailed record-keeping and communication during shift handovers (Wikipedia).

10. 2014 Dupont La Porte Toxic Chemical Leak

On November 15, 2014, the Dupont chemical plant in La Porte, Texas, suffered a catastrophic leak of methyl mercaptan, resulting in the deaths of four employees. The U.S. Chemical Safety Board investigation found that a series of communication failures during the shift handover led to the release of nearly 24,000 pounds of the toxic chemical. The Occupational Safety and Health Administration (OSHA) fined Dupont $273,000 for safety violations, and the company was placed in the Severe Violator Enforcement Program. The incident highlighted the severe consequences of poor communication in high-risk industrial environments (Wikipedia).

How Digitization Could Have Helped Avert These Tragedies

Reflecting on these incidents, it’s clear that a common thread linking them is a breakdown in communication during shift handovers. In each case, crucial information was either poorly communicated, misinterpreted, or entirely omitted, leading to disastrous consequences. Here’s how digitization, particularly through Innovapptive’s Digital Shift Handover solution, could have played a pivotal role in averting these tragedies:

1. Real-time Data Access: Digital platforms provide real-time access to operational data, ensuring that all relevant information is available to the incoming shift. This could have prevented the oversight in the BP Deepwater Horizon incident, where critical well integrity data was not communicated effectively.

2. Centralized Data Repository: A centralized digital repository ensures that all shift handover information is stored and accessible. This could have mitigated the issues in the Dupont La Porte chemical leak, where information was lost in manual handover processes.

3. Automated Alerts and Notifications: Digital systems can automatically alert workers to critical tasks or anomalies, ensuring that nothing is overlooked. In the Piper Alpha disaster, automated alerts could have prevented the use of a safety valve that had been incorrectly replaced.

4. Digital Checklists: Digitized checklists ensure that all tasks are completed before a shift ends. In the case of the KiwiRail derailment, digital checklists would have ensured that all maintenance tasks were tracked and completed.

5. Structured Communication Protocols: Digitization enforces structured communication protocols, ensuring that all necessary information is conveyed during handovers. This would have been crucial in preventing the BP Texas City Refinery explosion, where startup procedures were not properly communicated.

6. Task Tracking and Progress Monitoring: Real-time task tracking ensures that no task is left incomplete. This could have averted the Buncefield fire by preventing confusion over pipeline operations.

7. Compliance and Safety Protocol Automation: Digital solutions automate compliance with safety protocols, ensuring that all procedures are followed. This would have reduced the risk in the Esso Longford gas explosion by flagging incomplete handovers.

8. Improved Visibility and Accountability: Digital platforms provide improved visibility into operations, ensuring accountability for all shift workers. This could have prevented the Continental Express aircraft crash by ensuring that all maintenance tasks were completed and communicated.

9. Error Reduction Through Automation: Automating the shift handover process reduces the likelihood of human error, as seen in the Sellafield Beach incident. Digital systems would have ensured accurate communication of tank contents.

10. Integration with Other Systems: Digital shift handover solutions can integrate with other operational systems, providing a holistic view of ongoing processes. This integration could have prevented the Kleen Energy explosion by ensuring consistent communication of safety procedures.

The Role of Innovapptive’s Digital Shift Handover Solution

Given these past incidents, it is evident that digitization of the shift handover process is not just a matter of convenience, it is a critical component of industrial safety and operational efficiency. Innovapptive’s Digital Shift Handover solution is designed to address these exact challenges by offering a comprehensive and integrated platform that ensures all relevant information is captured, shared, and acted upon.

Key Features of Innovapptive’s Solution

- Real-time Data Access: Workers have access to real-time operational data, ensuring that the incoming shift is fully informed of the current status and any ongoing issues.

- Automated Alerts: The system generates automated alerts for any anomalies or critical tasks that need immediate attention.

- Centralized Data Repository: All shift handover data is stored in a centralized repository, allowing for easy retrieval and review by all relevant personnel.

- Task Tracking: The platform provides robust task tracking capabilities, ensuring that no task is left incomplete during shift changes.

- Safety Compliance: The solution helps ensure compliance with safety regulations by automating and documenting all safety protocols.

Interested in making your shift handovers more reliable?

Ensure your shift handover processes are secure, accurate, and reliable. Request a demo of Innovapptive’s Digital Shift Handover solution today and discover how it can help you prevent future incidents and protect your workforce.

FAQs

- Q1: How does a digital shift handover system improve safety in industrial environments?

A) Digital shift handover system improves safety by ensuring that all critical information is captured and communicated effectively between shifts. This reduces the risk of human error and ensures that all safety protocols are followed. - Q2: How does digitization prevent communication breakdowns during shift handovers?

A) Digitization prevents communication breakdowns by automating the capture and sharing of all relevant information. This ensures that no critical data is lost and that all team members are on the same page. - Q3: What industries benefit the most from digital shift handover solutions?

A) Industries with complex and hazardous operations, such as oil and gas, chemicals, mining, manufacturing, and utilities, benefit the most from digital shift handover solutions due to the critical nature of their operations. - Q4: Can Innovapptive’s solution be integrated with existing systems?

A) Yes, Innovapptive’s Digital Shift Handover solution is designed to integrate seamlessly with existing systems, providing a unified platform for all shift handover activities.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”