Asset tagging and Geocoding : Are your Fixed Assets Periodically Tagged, Reconciled and Geo-Coded to Prevent Theft?

Maintaining accurate, real-time data on asset status and location is a challenging yet essential task for organizations of all sizes. Fixed asset tagging and geocoding offer cost-effective, efficient solutions for recording and updating asset information, ensuring financial records remain up-to-date and accurate.

The Enterprise Fixed Asset Tracking Challenge

For enterprises—from small businesses to Fortune 500 companies—managing fixed assets is a crucial yet often complex responsibility. Financial teams understand the importance of asset tracking, but traditional methods and costly software frequently fall short in providing current insights into asset locations, conditions, or usage.

Without systematic asset tracking, organizations face gaps in asset accountability over time, especially when assets move between locations or partners. This lack of asset visibility creates risks, such as potential asset loss or theft. When there’s no system in place to track assets, it’s challenging to ensure they’re still where they should be, leaving enterprises vulnerable.

Taking Preventative Action with Mobile Fixed Asset Tagging Solutions

An enterprise can take preventative measures to protect its investments by implementing a mobile fixed asset tagging and reconciliation solution. Simple and cost effective mobile solutions integrated to your SAP or ERP system can track fixed assets along with barcode tracking tools, which then later make physical audits faster and more accurate. The practice of tracking assets and conducting periodic physical audits can help better manage an asset register and recognize theft. It also has the added benefit of helping to notice shrinkage, deterioration, misuse or loss of assets.

To secure valuable assets and investments, enterprises can deploy mobile-based asset tagging and reconciliation solutions. Innovapptive’s mobile solutions integrate seamlessly with SAP and ERP systems, utilizing barcode tracking tools to speed up physical audits, improve accuracy, and ultimately reduce asset management costs. Regular asset tracking and physical audits can reveal issues like shrinkage, wear, misuse, or loss—protecting enterprises from unexpected asset depletion.

The Enterprise Mobility Disruption – Redefining Processes and Simplifying Fixed Asset Tagging and Reconciliation

Mobility is revolutionizing how businesses operate and provides enterprises a unique opportunity to leverage a simple and cost effective self-service asset inventory verification solution. Innovapptive provides an award winning SAP® certified solution to redefine your existing manual, cumbersome or expensive processes to better manage and track your fixed assets.

A Centrally Managed Asset Reconciliation Process with Mobile Will Transform Your Enterprises Financial Pain Points. Innovapptive’s SAP® certified mobile asset tagging and geocoding solution (mAssetTag) is fully integrated with your SAP system and provides an Add-On module in SAP for your to seamlessly conduct physical asset reconciliation.

How Does the mAssetTag Solution Work?

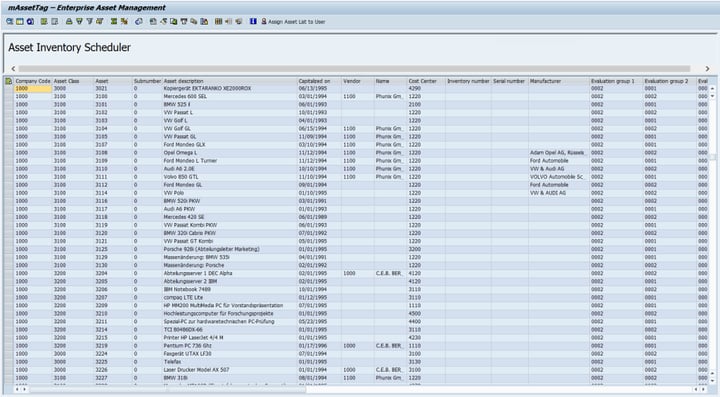

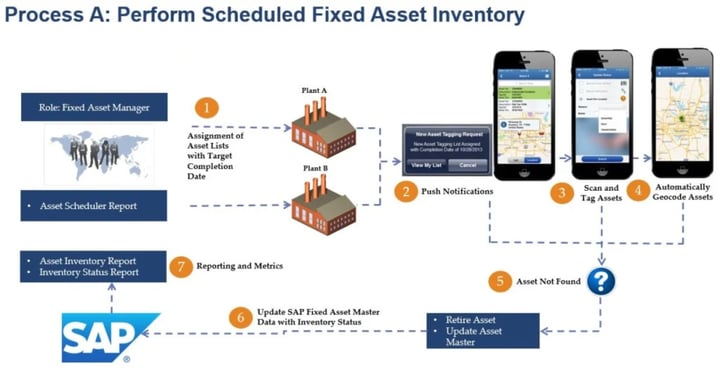

- Centralized Asset Verification and Reconciliation Scheduler: Innovapptive’s mAssetTag allows asset managers to manage and schedule periodic reconciliation based on location or plant. With this feature, managers can select asset batches and assign tasks with deadlines to authorized employees for streamlined asset audits.

![]()

- Push Notifications for Asset Reconciliation: Innovapptive’s solution enables push notifications on employees’ mobile devices, alerting them to fixed assets requiring reconciliation. This feature ensures timely asset tracking and fosters proactive asset management.

- Scan, Tag, and Geo-Code Assets: With the “Near Me” function, employees can easily locate and scan nearby assets using their mobile device, instantly pulling current information from SAP’s asset master record. This functionality includes inventory notes, status updates, and GPS-driven geolocation for precise tracking.

- Add New Assets and Print Bar Codes: Employees can add new assets as needed, recording basic information and generating barcodes directly from the mobile device for immediate asset tracking.

- Monitor Reconciliation and Requests: Innovapptive’s utility tool in SAP enables asset managers to monitor asset reconciliation progress, review statuses, and approve or reject updates. SAP’s asset master record is instantly updated, keeping asset data synchronized.

Several Fortune 500 companies have already started to adopt Innovapptive award winning solution and saving millions of dollars by proactively preventing theft and up-to-date information of the current operation state of their fixed assets.

Will your enterprise be next? Contact us to schedule a demo of our solution. Reach us via email at sales@innovapptive.com or call a sales representative at (713) 275-1804.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”