Better Cycle Counting with an Inventory Management Mobile App

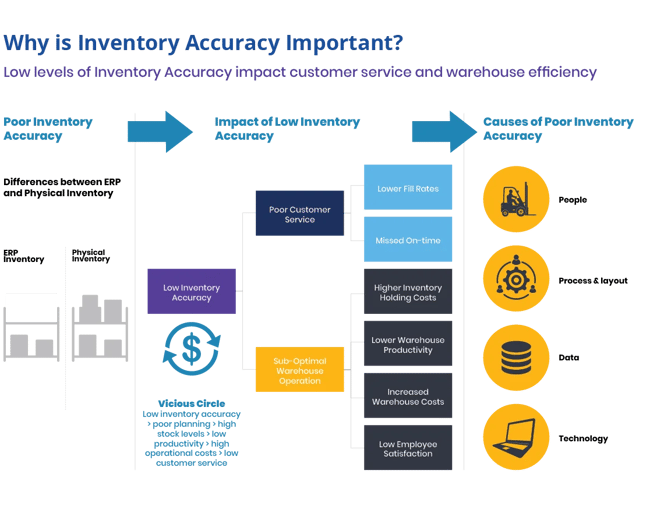

Stock accuracy is a critical warehouse KPI, ensuring that inventory management processes operate efficiently and warehouse staff maintain accurate stock records. If your warehouse struggles with inventory accuracy, implementing a structured cycle counting process through an inventory management mobile app can transform your operations.

What is Cycle Counting?

Cycle counting is a crucial process that helps inventory managers identify and resolve inventory discrepancies before they escalate. By regularly capturing and tracking cycle counts, businesses can improve inventory accuracy and financial statement reliability.

The process involves:

-

Physically counting a subset of warehouse products at scheduled intervals.

-

Comparing physical counts with system stock levels to identify mismatches.

-

Investigating and resolving discrepancies promptly.

A well-structured cycle counting program ensures that high-volume inventory is counted more frequently than slow-moving stock, optimizing warehouse efficiency.

Problems with Inefficient Cycle Counting

Without a structured cycle counting process, warehouses face challenges such as misplaced inventory, delays in stock retrieval, and customer dissatisfaction. Some common reasons for neglecting cycle counting include staff shortages, prioritizing order fulfillment, and limited time. However, ignoring cycle counting can lead to:

-

Declining Warehouse Productivity – Time wasted searching for misplaced materials impacts overall efficiency.

-

Compromised Customer Service – Inaccurate stock levels result in unfulfilled orders, leading to poor customer satisfaction.

-

Increased Inventory Shrinkage – Missing stock leads to financial losses and disrupted warehouse operations.

Mobile Inventory Management for Accurate Cycle Counting

Cycle counting provides a superior alternative to traditional annual stock counts, but manual data entry and paper-based processes reduce its effectiveness. Modern mobile inventory management solutions streamline cycle counting and improve inventory accuracy.

Benefits of Mobile Inventory Management Apps

-

Eliminates Paper-Based Count Sheets – No more handwritten records or manual data entry errors.

-

Enhances Real-Time Visibility – Digital systems provide up-to-date inventory insights.

-

Accelerates Counting Process – Barcode scanning reduces cycle counting time by up to 50%.

-

Seamless ERP Integration – Automatically updates stock levels in SAP and ERP systems.

Using barcode scanners, wearables, and smartphones, warehouse teams can capture inventory data instantly, reducing errors and improving supply chain accuracy.

The Importance of Inventory Accuracy

An advanced mobile inventory management solution, like Innovapptive’s mInventory app, significantly enhances the cycle counting process, improving warehouse efficiency. mInventory integrates seamlessly with ERP systems, allowing warehouse teams to:

-

Scan barcodes for precise inventory tracking.

-

Receive guided instructions for counting bin locations.

-

Eliminate manual paperwork and redundant data entry.

-

Ensure real-time inventory visibility across locations.

During cycle counting, the handheld device guides the user to the bin location of the designated materials. Scanning the material barcode confirms the correct product, and the worker can directly input the physical count into the device. This eliminates the need for paper count sheets, handwritten entries, and separate data entry by office staff. The result? A faster counting process with minimized data entry errors.

Accurate inventory data improves warehouse performance by reducing stock discrepancies and enabling real-time decision-making. During cycle counting, mobile devices guide users to the correct bin location, confirm product identification through barcode scanning, and allow direct input of physical inventory counts. This eliminates paper-based reporting, ensuring a faster and more reliable counting process.

Transform Your Warehouse Productivity With Innovapptive

Experience Connected Inventory Management with Innovapptive’s mInventory app. Learn how our solution enhances cycle counting efficiency, minimizes warehouse errors, and improves overall inventory management.

Call 888-464-6668 or schedule a free demo today to explore how mobile inventory management solutions can revolutionize your warehouse operations.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”