Companies Confront Higher Downtime Costs; Can Mobile Plant Maintenance Offer a Solution?

In-house labor isn’t cheap. Using outside contractors is even more expensive. Those costs are sure to increase as companies of all kinds struggle to find workers in the current tight employment market. Can an easy-to-use mobile maintenance management app help?

Labor is one of the biggest line items in any maintenance budget. If organizations can’t fully staff their maintenance departments, they’ll have to turn increasingly to outside contractors to accomplish necessary tasks, especially during planned and unplanned downtime. This can threaten to bust the budget. To save money, companies may curtail maintenance activities, which increases their risks for equipment failure and unplanned downtime, creating a vicious and costly cycle.

In part one of this three-part series, we’ll examine how inefficient maintenance programs result in higher labor costs.

Downtime and Ever-Higher Maintenance Labor Costs

The average manufacturing plant suffers 800 hours of downtime a year. That’s an average of more than 15 hours a week. Overall, unplanned downtime costs industrial organizations and manufacturers as much as $50 billion a year.

Half of all manufacturers still use reactive, run-to-fail maintenance. That could explain why more than seven out of 10 plants have no real idea when their production equipment is due for maintenance, upgrades or replacements.

Short-staffed organizations have to pay overtime when an unexpected maintenance emergency occurs. They’re also increasingly turning to outside contractors to supplement their in-house maintenance staff.

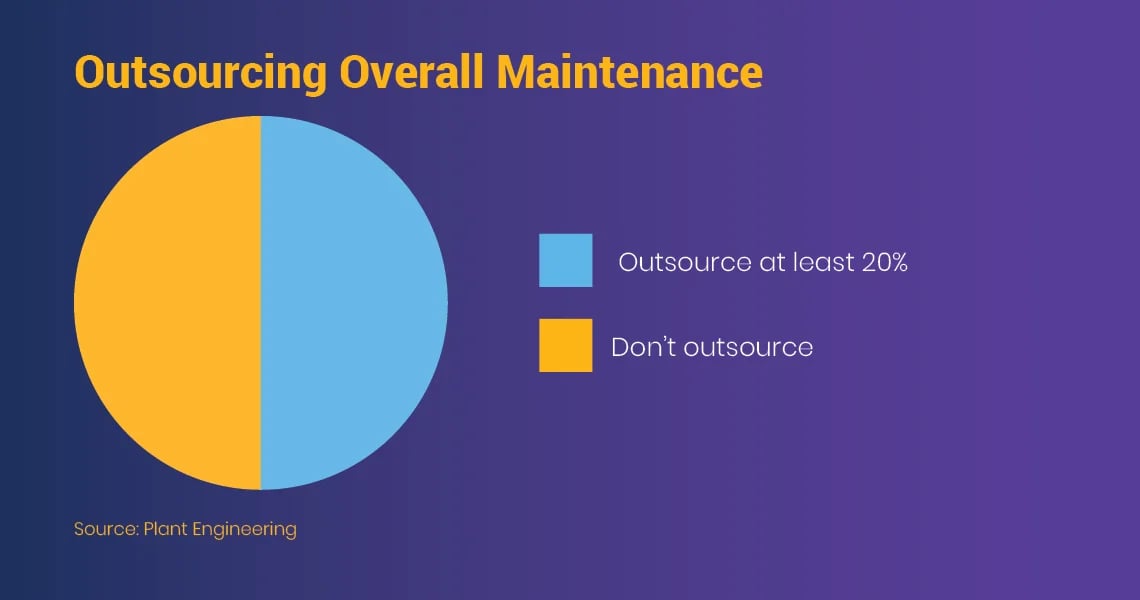

Half of all companies outsource at least 20% of their overall maintenance; 10% use a contractor to perform half or more of their maintenance activities, including repairs during planned and unplanned downtime incidents.

Overtime and contractor expenses quickly add up. Maintenance managers face a tough choice: either improve their processes to increase technician productivity, boost overtime, and continue to employ expensive outside contractors or cut activities to save funds and risk more unscheduled downtime.

Downtime Inflicts Other Costs, Too

Unplanned downtime has far more costs than just maintenance expenses. There are also hidden labor costs that quickly add up each hour a piece of equipment is offline for repairs. For example, equipment operators still must be paid whether the machine is running or not. This cost is often overlooked.

Then, of course, is lost production. Shutdowns can devour from 1% to 10% of available production time. Those lost hours can’t be recovered. That puts added pressure on customer relationships when orders can’t be met. It also squeezes profit margins.

Improving manual, paper-based maintenance processes can reduce unplanned downtime and cut these additional hidden costs.

Mobile plant maintenance systems and connected worker solutions enable frontline workers such as technicians and operators to get their jobs done faster, better, safer and cheaper. Instead of paper forms, checklists and binders, frontline workers perform tasks using mobile devices, including smartphones, tablets, smart glasses, smartwatches and scanners. This greatly speeds getting critical operational data into the hands of decision-makers who can more effectively allocate labor and material resources and issue work orders to resolve issues before they become downtime-causing problems.

In part two of this series, we’ll look at how accurately capturing wrench time is key to lowering plant maintenance costs.

Coming next: Accurately Capturing Wrench Time Key to Lowering Plant Maintenance Costs.

Want to Learn More?

Innovapptive, a connected worker solution pioneer, specializes in mobile plant maintenance systems that improve technician productivity, transform reactive processes and cut downtime costs. Schedule a free demo of a world-class connected worker platform or call 888-464-6668 to speak to our industry experts. They’ll be happy to answer your questions, help you calculate return on investments, identify opportunities for efficiencies and savings, and explain how mobile plant maintenance can benefit you.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”