Effective Preventive Maintenance In Oil and Gas Facilities with Visual Planner

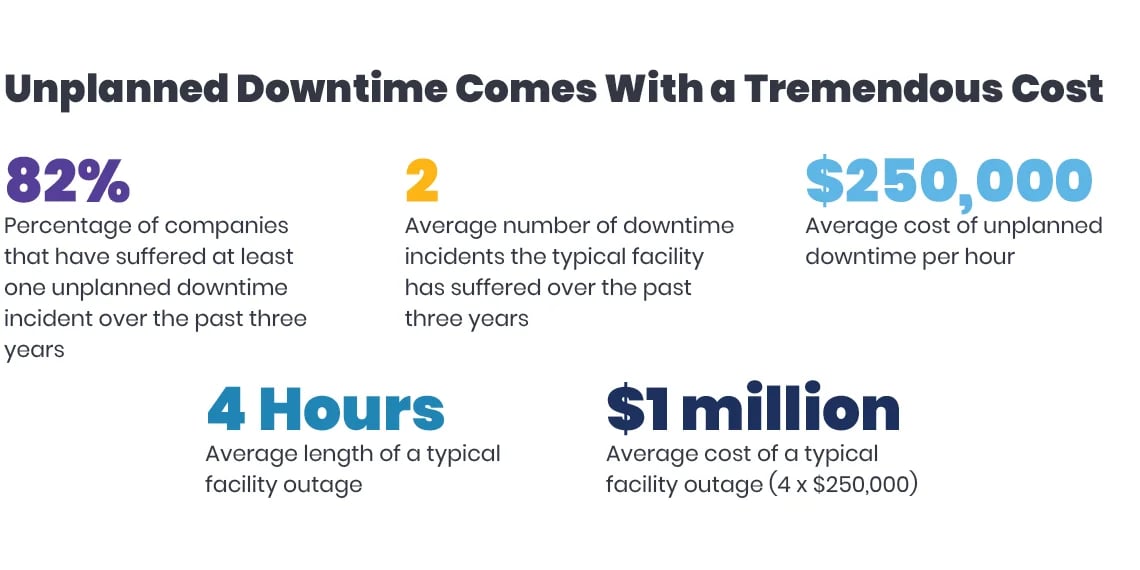

In a capital-intensive oil and gas industry that operates in a tough environment, preventive and corrective maintenance activities are essential for seamless operations. Effective preventive maintenance in oil and gas, therefore, needs meticulous planning and scheduling. A robust preventive maintenance strategy is required to avoid the risk of unplanned downtime and ensure cost-optimized maintenance planning, scheduling, and execution.

Refinery turnarounds are massive undertakings requiring years of careful planning and precise coordination. Timely and accurate information is essential to the successful construction of any turnaround plan. Many planners, unfortunately, still use paper to organize a framework, timely map out each project step, track needed parts, and materials, allocate critical resources, solve problems, monitor progress, and communicate with stakeholders.

This process is inefficient and delays work progress, increasing the risks of additional and costly downtime. Such paper-based systems are slow, unwieldy, and error-prone, especially in emergencies like an unplanned shutdown or outage where decisions need to be made quickly.

Digital Maintenance Planning and Scheduling

Refinery planners need greater flexibility, agility, visibility, and speed. They need a better process and the tools to perform their jobs more effectively. Mobile-based digital planning systems are accurate and efficient that can overcome these challenges and make for a smoother, more predictable, and manageable process.

Future forward companies are adopting digital solutions for planning and scheduling to eliminate paper and make oil and gas maintenance planning and scheduling streamlined. Digital maintenance planning and scheduling offer a solution that enables the key personnel to better focus on what’s important when preparing for an outage, shutdown, or turnaround.

Benefits of Digital Planner

Effective, proactive maintenance planning and scheduling is the first step in reducing revenue-draining downtime incidents. Visual Planner cuts the costly delays and wasted time associated with spreadsheet scheduling methods. Plant maintenance schedulers and planners gain real-time visibility into resources and asset availability. They can move faster to scope projects, and assign people and materials, giving them greater agility even in an emergency.

Visual Planner helps refinery maintenance planners:

Minimize maintenance costs: Allows for proactive maintenance programs that reduce asset breakdowns and cut preventable equipment failures.

Eliminate paperwork: Manual planning with paper-based processes is tedious and error-prone involving non-value-added tasks.

Maximize productivity: Quickly develop turnaround plans, allocate resources, manage materials and reduce overtime.

Extend and boost asset life and reliability: Better maintained assets run smoother, encounter fewer operational problems, and last longer resulting in a better return on investment.

Improve safety: Clearer, more thorough plans and instructions result in safer maintenance operations and fewer incidents.

Case For Visual Planner

Visual Planner ensures smooth operations in case of an emergency outage. Planners don’t suffer from delays stemming from paper-based processes. Real-time visibility means faster response times in situations where time is critically important, from production, customer service, revenue, and safety standpoints.

With an intuitive, easy-to-use dashboard, planners and schedulers can:

- Perform capacity planning and long-term work leveling

- Put in place an efficient multi-week rolling schedule based on business plan requirements

- Approve and lock next week’s schedule

- Check parts availability and perform kitting

- Assign a full crew to a shift in seconds

- Monitor schedule compliance rigorously

Streamline Your Maintenance Planning and Scheduling

Schedule a free demo of Visual Planner today to learn how the solution can make your planning and scheduling faster and more efficient, improving productivity, increasing asset reliability, and preserving revenue flows. Or, call 888-464-6668 to speak to one of our oil and gas industry experts today.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”