Release Announcement: mWorkOrder 7.2

The Q3-2019 release for mWorkOrder is now available. This latest release of mWorkOrder includes some exciting new features and capabilities.

Embed Multiple Custom Digital Forms

- Eliminate paper-based forms associated with work orders and now associated with notifications

- Embed one or many customized forms with customized fields

- Capture form content, save drafts, submit final versions and view history

Custom Tabs

Enhance your work order and notification data with the ability to bring in custom screens and fields on your standard objects.

- Enhance mWorkOrder with custom work order tabs to meet specific business needs

- Configure custom tabs in RACE for use when executing work orders in the field

- Custom tabs can include multiple sections, line items, fields, fonts, colors and more

In App Context-sensitive Help

Context-sensitive help, or just “context help”, is customizable user documentation within mWorkOrder, which is smart enough to deliver the right content at the right moment. This type of documentation is embedded into the application itself, and available in online and offline modes. Contextual, step-by-step images, videos and text will help end-user customers use and adopt mWorkOrder when unfamiliar to increase end-user adoption.

- Easy-to-understand help for product capabilities

- Available online and offlineBenefits

- Increased customer satisfaction and end-user engagement

- Fewer end-user issues and frustration from improper application use

Configurable Risk Matrix / Priority Determination through RACE™

The maintenance criticality matrix, or risk matrix, can help maintenance teams and plants assess the criticality of a given risk. Structures often use it when they want to manage, anticipate and annihilate potential failures. Prioritize maintenance work orders based on the risk profile of all equipment throughout the facility.

- Use risk information to prioritize work orders

- Factors include severity, likelihood and duration

- Embed risk and safety measures information in safety plan section of work orders

- Improve prioritization of work orders based on severity and likelihood of impact

- Improve technician health and safety

PDF Document Markup

Highlight, annotate and add signatures to PDF documents available within mWorkOrder. Add commentary to PDF documents, highlights or flag areas of importance.

- Check off items on a checklist

- Add signatures for verification

- Improved visibility of important content

- Enhanced ability to correct documents or highlight areas of concerns

- Improved traceability of signed documents

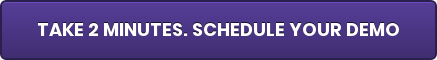

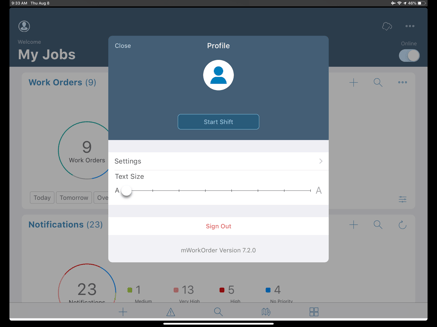

Configurable Font Size

Use the slider to fully configure the font size across the application.

- Improve readability of work orders, notifications and other mWorkOrder capabilities with adjustable font sizes

- mWorkOrder users can choose the font size that works best for them

.

.

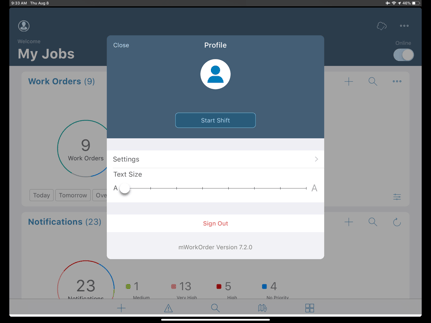

Online/Offline Toggle Button

Improve usability in areas with limited connectivity by allowing mWorkOrder users to manually switch between online and offline modes. Automated online/offline switching works great when connectivity is clearly available or unavailable; allowing mWorkOrder users to make that decision ensures they can remain productive when low bandwidth slows access to backend data.

Improve usability in areas with limited connectivity by allowing mWorkOrder users to manually switch between online and offline modes. Automated online/offline switching works great when connectivity is clearly available or unavailable; allowing mWorkOrder users to make that decision ensures they can remain productive when low bandwidth slows access to backend data.

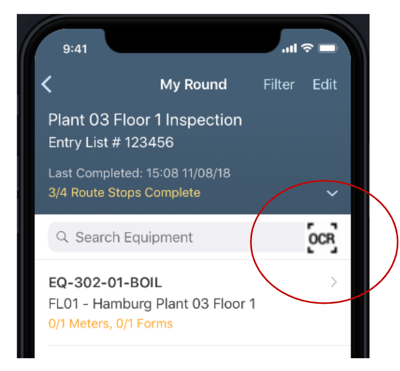

OCR Integration

Optical character recognition enables mWorkOrder users to more quickly access equipment and functional location information and maintenance plans. It eliminates the need to manually enter asset tag or other equipment/FLOC identifiers. In addition, it can be used to capture asset and maintenance information for new equipment/FLOCs more quickly and accurately.

Optical character recognition enables mWorkOrder users to more quickly access equipment and functional location information and maintenance plans. It eliminates the need to manually enter asset tag or other equipment/FLOC identifiers. In addition, it can be used to capture asset and maintenance information for new equipment/FLOCs more quickly and accurately.

- Access equipment and FLOC information based on scanned asset tag and other identifiers

- Capture and store asset information for new equipment and FLOCs installed in the field Benefits

- Improve speed of access to equipment and FLOC information and maintenance plans

- Improve accuracy of asset tracking for new equipment/FLOCs

- Improve engagement and user experience for technicians wearing gloves or who have difficulty typing

Reprocessing of Failed Transactions

-

- Resubmit transactions that fail during a backend sync when transitioning from offline mode to online mode

- mWorkOrder users can resubmit these transactions from the Offline Outbox associated with work orders, notifications, equipment and functional locations.

Log History Enhancements

- Consistent Localization Keys

- Localization is now based on screen name and module name

For Android devices and the UI5 interface, mWorkOrder v7.2.0 now includes the ability to collapse sections of embedded forms. This is useful when working longer or more complex custom forms allowing users to focus on specific sections while minimizing excessive vertical scrolling. This capability is already available for iOS devices.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”