Mobile Inventory Management Solution for Mine-to-Market Transfer

Within the mining value chain, one of the biggest challenges companies face is to overcome challenges in supply chain management. Managing inbound and outbound logistics along with efficient warehouse management has recently grabbed the attention of mining companies to maintain a competitive edge in the market.

As the business grows, an integrated supply chain process is required and so is prudent inventory management. Mining businesses need to handle multiple inventory transfers which comes with challenges like inconsistent processes, human errors and logistical complexities.

Companies need to ace the mine-to-market game to stay ahead of the competition.

Currently operating in organizational silos with limited coordination and no real-time data exchange, many mining companies are stuck in a rut. Let’s delve deeper into ways of enhancing the mine-to-market value chain and the importance of effective inventory transfers within the ecosystem. In this blog, we explore a mobile solution that ensures effective and accurate inventory management.

Inventory Transfer in Mining Industry

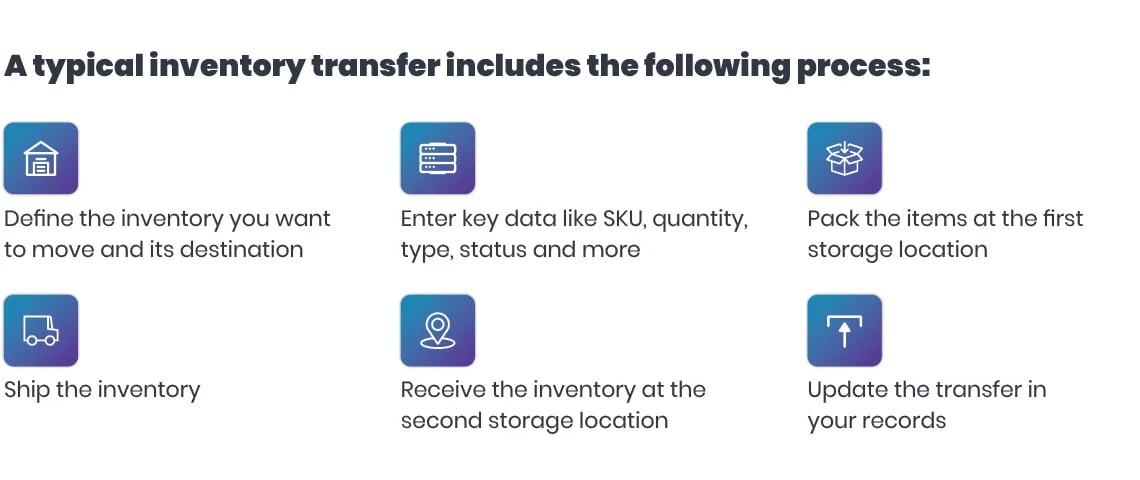

An inventory transfer is when goods are transferred from one location to another. Location here refers to a mine, storage location, or warehouse.

Though it looks simple, the real challenge occurs when you handle multiple inventory transfers back and forth. Several factors play a major role in ensuring inventory efficiency. These include your storage location layout and the placement of barcodes on boxes.

Challenges Faced During Inventory Transfers

Miscommunication is one of the most pressing challenges of inventory transfers. Knowing what's being transported, any miss during transit, and time can be tough to track across multiple locations. Above all, if you still rely on manual processes or lack access to a real-time picture of inventory activity, this will predictably lead to huge losses.

Mobile Inventory Management

An automated inventory management application that can sync in real-time across multiple locations guarantees consistent communication and improves accuracy. You can get a comprehensive view of what was transported, how much, when, where and other relevant information you want to incorporate. It eliminates guesswork and error-prone paper data entry.

New-age digital technologies help remove the common challenges and create an integrated environment. For instance, mobile inventory management offers real-time visibility and accessibility across the mining supply chain. It gives better control over inventory and offers traceability during an inventory transfer. Any misplaced item is immediately identified and corrective action is taken on time.

Ready to Have Efficient Inventory Transfers from Mine to Market?

Innovapptive’s mobile inventory management solution – mInventory – offers the right choice for your warehouse managers to optimize and manage inventory transfers. mInventory offers agility, flexibility and seamless integration between your core inventory processes and back office systems. To improve your stock transfers for measurable gains with mInventory, schedule a free demo today by calling 844-464-6668.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”