Mobile Solutions for SAP Extended Warehouse Management (EWM) – Comparing mInventory with SAP Fiori & ITS Mobile

By Richard Sandall

Supply Chain Evangelist

SAP Extended Warehouse Management (EWM) is a best-of-breed solution capable of managing medium- and high-complexity warehouses operations. This includes warehouses on a manufacturing site used for raw material and finished goods storage as well as standalone distribution centers for finished goods. EWM is a feature-rich warehouse system that will help organisations meet the challenge of fast-changing customer service expectations and the constant pressure to increase warehouse productivity.

If you have made the decision to go with EWM, the next important decision to make is what mobile solution to select, which is equally as important. The mobile solution is where the “rubber hits the road” since it is how users get access to all that great backend EWM functionality.

A Little Extended Warehouse Management History

The deployment of mobile solutions has had a chequered history in many organisations. Early adventures included building solutions in-house or using Systems Integrators. Whilst the first warehouse deployment may well have gone okay, roll outs often got bogged down as inflexible, hard-coded solutions could not reflect different warehouse processes, language requirements and other localisations. Solutions were expensive to maintain as coders had to be bought in to do the smallest update.

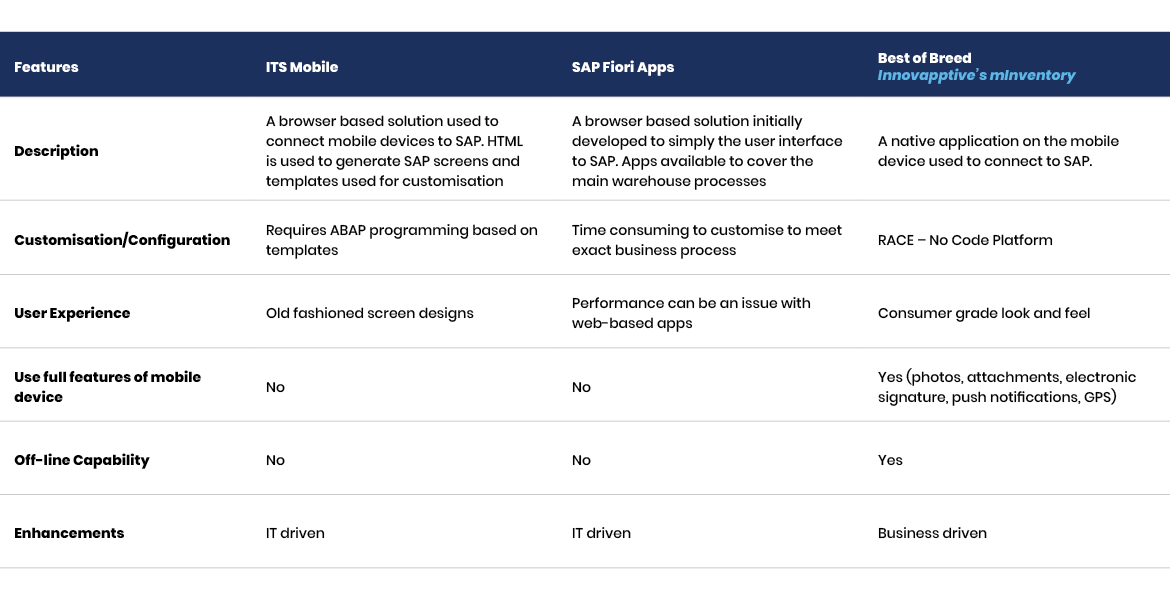

The table below provides a comparison of three mobile options for EWM:

Issues with SAP’s Extended Warehouse Management Options

SAP’s two options to provide the mobile front-end to EWM are ITS Mobile and Fiori Apps. ITS Mobile is the older solution and since 2013 SAP has focused on Fiori apps as the way to integrate mobile devices with EWM. ITS Mobile and Fiori apps share some similar characteristics. They are both browser-based solutions that use HTML to put SAP information on a mobile device, but they have drawbacks. They require expensive coding resources to make even small changes to reflect the exact warehouse process required by customers.

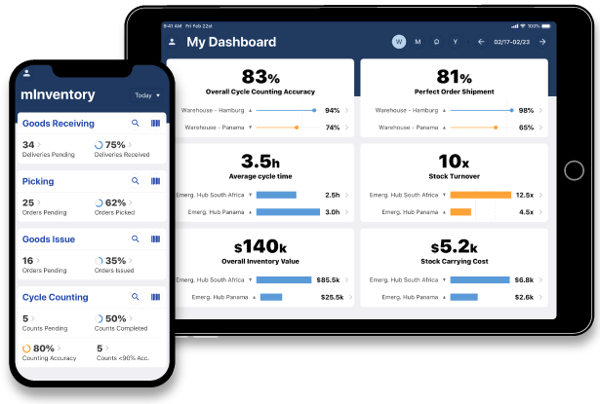

ITS Mobile screens looked very dated, especially when compared with today’s smart phones, which younger members of the workforce have been brought up on. Browser solutions can be slower to interact with the backend EWM system, which can be very frustrating for users in a high throughput warehouse. In contrast, native mobile applications, such as mInventory from Innovapptive, have faster response times and the look and feel that users see on their own modern smart phones.

How Innovapptive’s Solution Differs

The major benefit of a native mobile application is that they can leverage the full features of a modern mobile device that can improve warehouse processes and productivity. This includes, photos, videos, GPS, push notifications, attachments, etc. Another major advantage of mInventory is the capability to operate offline without a Wi-Fi or public network. This avoids a common problem of users losing information when they enter a Wi-Fi blind spot in the warehouse.

A final big advantage for mInventory is that it comes bundled with RACE™, Rapid App Configurator Engine, our patented No-Code Platform. This is our secret sauce, a powerful tool that will supercharge any EWM roll-out and overcome the challenge of scalability that doomed many early mobile deployments. RACE speeds deployment by allowing rapid localisation to meet different warehouse processes, mobile operating systems, or compliance requirements. RACE comes packed full of features to allow configuration of workflows, screens, design of barcode labels, device integration, design of digital forms and offline usage. IT staff or even business users can be trained on RACE so the organisation is empowered to support future business changes.

Discover the Advantage of mInventory for EWM

To learn more about mInventory and RACE visit our website by clicking here or call 844-464-6668 and speak to one of our experts today.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”