mWorkOrder – What’s New in Version 6.1 ?

Offering best-in-class and newly improved mobile solution for plant maintenance, Innovapptive is very pleased to announce the availability of mWorkOrder 6.1. Our teams have been putting continuous efforts to make sure that everything is primed and ready to go with the launch of our newest mWorkOrder 6.1 release. We are excited to share with customers the fantastic new features and capabilities available throughout our product portfolio!

mWorkOrder– Mobile Work Order Solution

Innovapptive’s mWorkOrder enables plant technicians/maintenance workers to work more safely, productively, and independently, providing an intuitive user experience and provides them anytime, anywhere access to the information they need to do their jobs efficiently and effectively. This SAP® Certified solution leverages the SAP Plant Maintenance (PM) module at the back-end to deliver a consistent, reliable and a productive asset maintenance experience across a wide range of industries.

With both online and offline access, mWorkOrder ensures delivery of mission-critical support of assets without interruptions or delays, leading to better performance and reliability across plants, fleets, networks, and the enterprise infrastructure. It helps users manage priorities in real time, as well avoid any potential equipment failure, unexpected downtime issues, and/or safety and environmental risks. With mWorkOrder, plant workers/technicians instantly are alerted through push notifications when they are assigned new work orders or notifications.

Innovapptive is constantly adding new features to our applications; adding new capabilities and extending existing ones, enabling the mobile workforce, thereby maximizing asset reliability and reducing maintenance costs. mWorkOrder 6.1 is no different! “We are excited to be able to offer a compelling and integrated Mobile Plant Maintenance solution to solve critical maintenance problems for our current and future customers,” Hari Kamineni, Co-Founder/Chief Product Officer, Innovapptive.

What’s New in mWorkOrder 6.1?

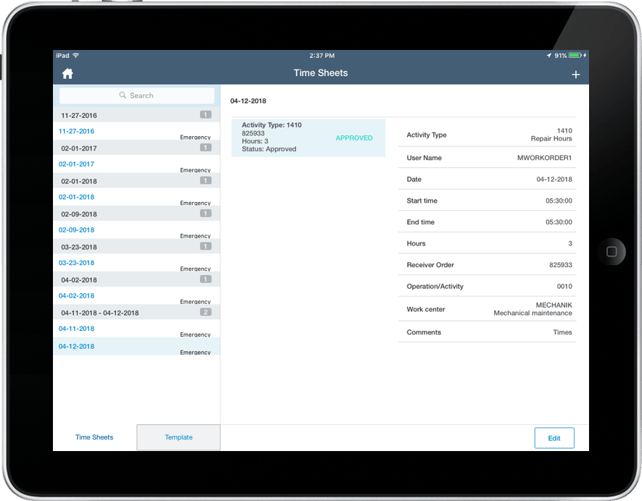

- Auto HR Timesheet

- Classification—Equipment

- Manual Work Order from Maintenance Plan

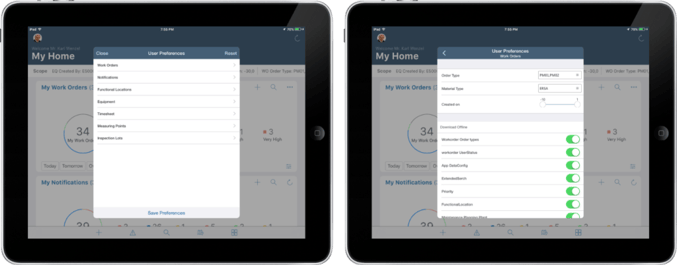

- User Preferred Offline Synchronization

- Offline Failed Postings Reprocessing (Android and Windows)

- UI Enhancement—History Navigation

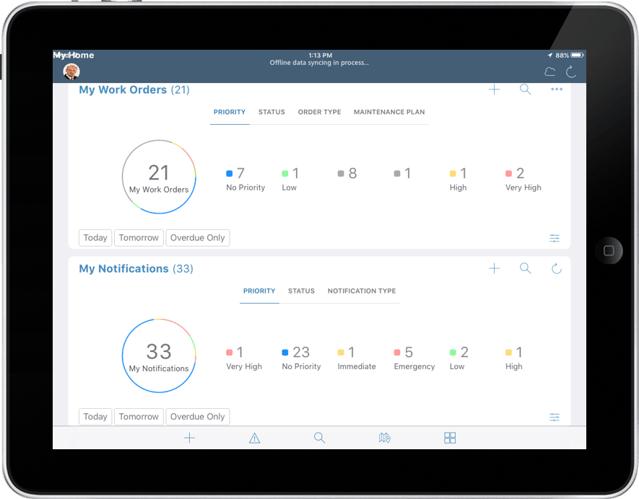

- Configurable Dashboard

- Color Coded Work Order Numbers in Work Order List

- Hierarchy Enhancements—Equipment and Functional Location

- Internet Explorer Compatibility—UI5

Auto HR Timesheet is a time saver for your plant supervisors/managers! Now they can easily keep track of a user’s productive and non-productive hours. You can gain actionable insight regarding how your maintenance workforce is impacting your organization’s bottom-line which will help decrease labour costs, improve maintenance operation execution and achieve unparalleled compliance.

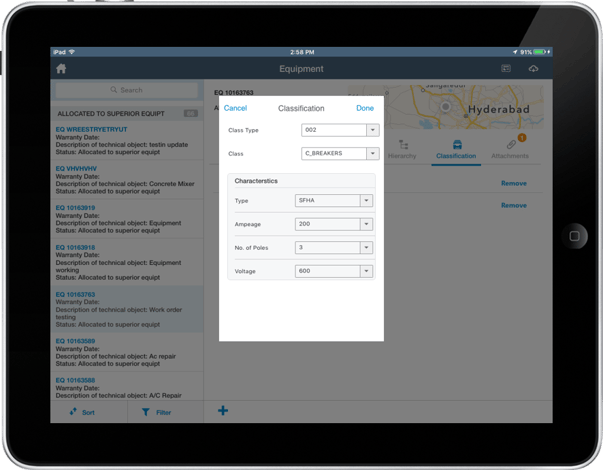

Classification—Equipment

Without having proper equipment details, creating an effective maintenance plan can be difficult for your maintenance worker. We’ve added a new tab, Classification, in mWorkOrder 6.1 which lets you provide your maintenance workers with all the necessary information of equipment such as Class, Class Type, and Characteristics of the equipment. One stop for all the details. Simple!

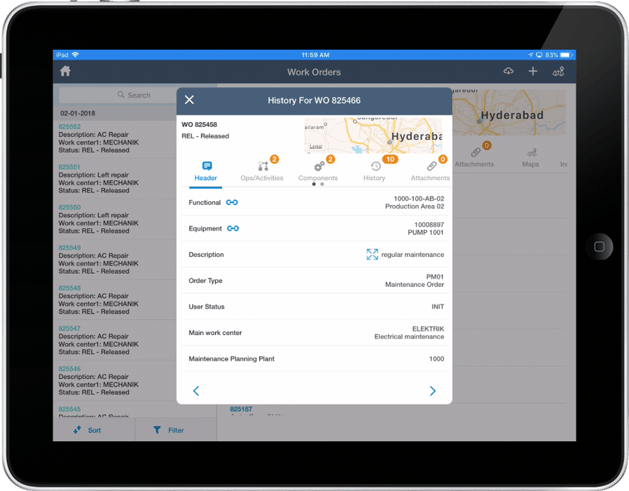

UI Enhancement—History Navigation

Lack of visibility into equipment history is a constant struggle for maintenance users & technicians, yet it is necessary tool to complete their work orders effectively. In mWorkOrder 6.1, we’ve enhanced the History navigation screen with easy identification and navigation capabilities to historic data of a Work Order.

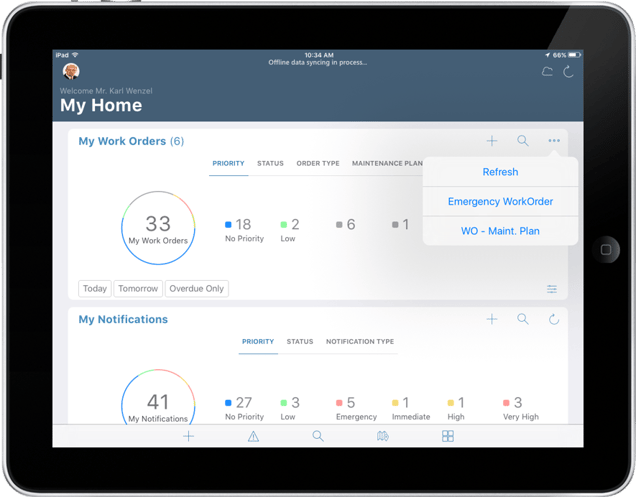

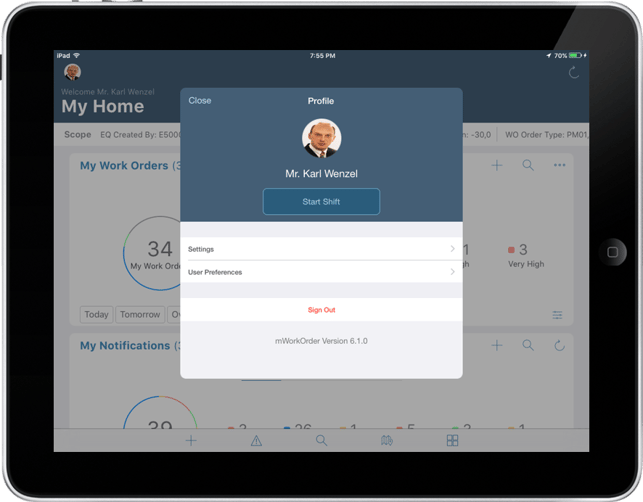

Configurable Dashboard

The entire point of enhanced Configurable Dashboard is to enable users to take better advantage of the available information. New capabilities such as Date Filter, Dashboard and Module level data filters, Tabbed Modules and more have been added in mWorkOrder 6.1. Moreover, users can easily search and create objects.

The Manual Work Order – Maintenance Plan feature of mWorkOrder 6.1 yields great benefit in efficiency to the Maintenance users. With 6.1, they can create work orders directly from the home page during preventive maintenance.

User Preferred Offline Synchronization is a high-demand new feature in mWorkOrder 6.1. Maintenance user (workers) can save their data in offline mode and the data is synchronized automatically when users are back within network range. They can configure their preferences for offline data synchronization for each of the modules.

Offline Failed Postings Reprocessing

Gone are the days when users must suffer due to lost network connectivity issues and/or write down information on paper. The newly added feature, Offline Failed Posting Reprocessing, in mWorkOrder 6.1, allows users to re-process the failed documents that were processed during offline mode. Now, they don’t need to write down information on papers.

We’ve highlighted our top updates, but there are many more exciting new feature and changes in mWorkOrder 6.1. If you’d like to read further, please refer to mWorkOrder 6.1 Release Notes.

We encourage our customers to upgrade to the latest version of the mWorkOrder to take advantage of the new and improved features.

If you would like a demo of Innovapptive’s mWorkOrder (Mobile Work Order Management) solution, please click on the link/button. Alternatively, If you would like to discuss with an Innovapptive Solution Expert, you can email us at sales@innovapptive.com or via phone at (713) 275-1804.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”