Innovapptive’s New Digital Operator Rounds Solves Unplanned Downtime and Safety Problems

HOUSTON –Connected Worker pioneer Innovapptive now offers industrial and manufacturing plants a robust mobile tool in their fight to curb costly downtime and boost safety compliance with its new Digital Operator Rounds solution.

“Excessive downtime and poor safety compliance are putting a serious crimp in plant profit margins,” said David April, Innovapptive’s senior director of product management. “Our Digital Operator Rounds solution enables equipment operators, plant maintenance technicians and environmental, health and safety (EHS) departments to identify potential equipment and compliance issues and take preventative or remedial action before they become expensive problems.”

The Case for Digital Operator Rounds

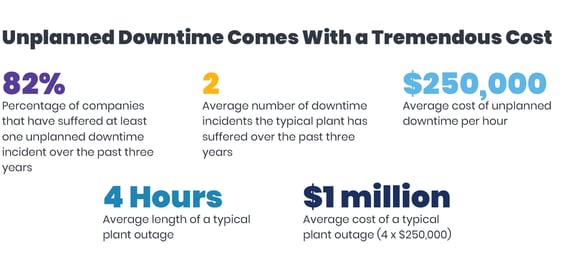

Source: Aberdeen Research

Unplanned production downtime costs plants an average of $250,000 per hour, siphoning away valuable revenue and profits. Many facilities in industries such as oil and gas, mining and metals, utilities, and manufacturing use paper checklists and clipboards to conduct daily equipment inspections. This paper-based process causes several problems, including:

- Labor-intensive manual data entry into SAP or another ERP.

- Incomplete or inaccurate information from data entry errors.

- A time lag between problem detection and preventative or remedial action.

- No way to upload multimedia files to provide a clearer picture of the problem.

“Plants managers want faster and better operational information to assess risk and prevent downtime,” April said. “Far too many sites are operating blindly, hoping for the best. While nearly three-quarters of plants recently surveyed said zero downtime was a top priority, 70% also reported they had no idea when their equipment was due for maintenance or upgrades. Digital Operator Rounds can change this.”

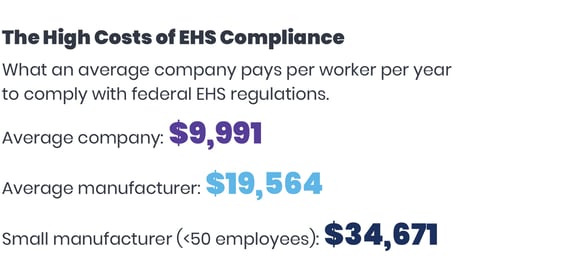

Source: National Association of Manufacturers

Source: National Association of Manufacturers

Safety compliance is another issue threatening profit margins. Most industrial accidents occur due to slips and falls or contact with objects and equipment. Plants are constantly looking for ways to reduce or eliminate safety risks and the resulting lost work time, fines and penalties.

“Digital Operator Rounds provide a way for customers to identify potential safety hazards during the daily inspection, assess risk and take timely action before any harm occurs,” April said. “This reduces cuts the number of incidents, boosts compliance and increases uptime.”

How Digital Operator Rounds Work

Innovapptive’s Digital Operator Rounds replace error-prone paper checklists with an efficient electronic process utilizing mobile handheld devices (smartphones, tablets, barcode scanners, etc.). Technicians access digital forms on their devices to conduct inspection rounds. These dynamic digital forms can be quickly and easily changed on the fly — unlike paper checklists — to better meet an industrial facility’s situational needs.

Technicians scan equipment barcodes and complete the digital form by checking customized data fields to document operational status and safety conditions. The inspector can’t advance to the next piece of equipment or location until all fields for the current step are completed as a safeguard. The solution immediately uploads collected data electronically into the back-office system. Decision makers can view inspection data in real time via their mobile device or desktop application and communicate with the technician during the round.

“Unlike a paper-based inspection, nothing is overlooked with Innovapptive’s Digital Operator Rounds,” April said. “Customers can address operational concerns, assess safety risks and take action before costly downtime happens.”

Learn More about Digital Operator Rounds

Digital Operator Rounds are part of Innovapptive’s Connected Worker platform. The platform helps plants improve their enterprise asset management and warehouse management processes. Click here to schedule a demo.

About Innovapptive

Innovapptive – a digital transformation pioneer – offers the only connected worker platform that digitizes the last mile of front-line workers into SAP and IBM. Innovapptive is a global leader for industrial connected worker solutions and its platform digitizes and integrates SAP, IBM Maximo and GIS operational data with work instructions, SOPs and checklists. The platform connects the entire industrial workforce, machines, workflows, executives and back office to minimize plant outages and maximize margins. By engineering a platform that fuels innovation and collaboration, Innovapptive is transforming the experience of the industrial worker to turn downtime into revenues, risks into safety, and inefficiencies into growth. Innovapptive is headquartered in Houston with offices in Australia, the Netherlands and India. Learn more at www.innovapptive.com.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.