Digitally Transform Your Mining Asset Maintenance and Operations Management

In the dynamic landscape of the mining industry, embracing cutting-edge digital solutions is crucial to ensure efficient and sustainable operations. By integrating mobile work order systems and visual planning tools into mining asset maintenance and operations management processes, mining companies can elevate their operations to new levels of productivity, safety, and cost-effectiveness.

Empowering On-the-Go Efficiency With a Mobile Work Order System

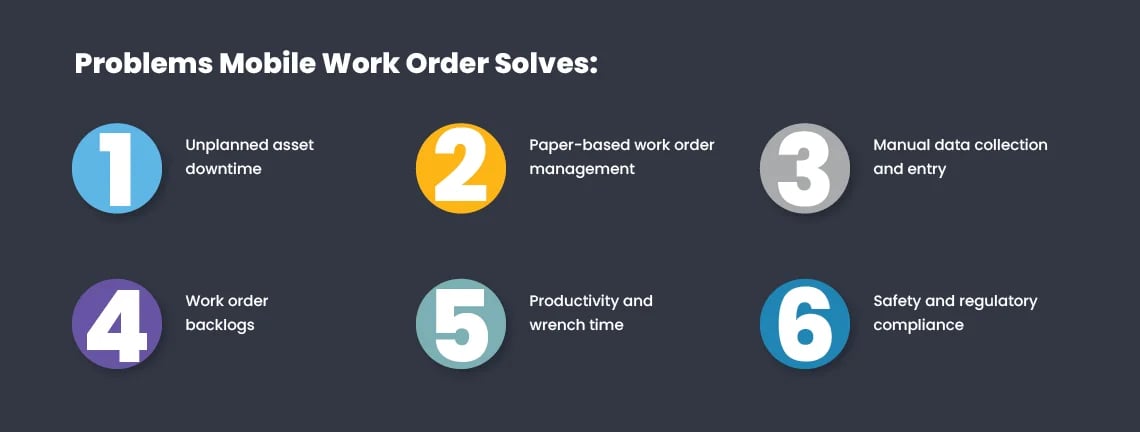

A mobile work order system revolutionizes how maintenance tasks are managed in the mining sector. Traditional paper-based systems are cumbersome and prone to errors and delays. By adopting a mobile work order solution, mining operation gains multiple advantages as follows:

- Real-time Accessibility: Allows maintenance teams with mobile devices that allow them to access work orders, update task statuses, and report issues instantly, no matter where they are on-site.

- Streamlined Communication: Enables seamless communication between field technicians and management, ensuring that all stakeholders are on the same page and informed about task progress.

- Enhanced Productivity: Empowers the workforce to complete tasks more efficiently by providing them with detailed instructions, relevant documentation, and historical data at their fingertips.

- Reduced Downtime: With quicker response times and instant access to maintenance histories, teams can resolve issues faster, reducing equipment downtime and maximizing operational uptime.

- Data-Driven Insights: Captures valuable data on maintenance trends, equipment performance, and resource utilization. Analyzing this data can lead to predictive maintenance strategies, reducing the likelihood of costly breakdowns.

Mapping Out Success With Visual Planning Solutions

Visual planning tools bring a new dimension to mining operations management. They offer a comprehensive view of tasks, resources, and timelines, enabling better decision-making and resource allocation by:

- Interactive Scheduling: Plan and manage maintenance tasks using intuitive visual interfaces. Drag-and-drop functionalities allow you to adjust schedules on the fly and allocate resources effectively.

- Resource Optimization: Visualize resource availability and workload distribution across different teams and projects, ensuring optimal resource utilization and preventing overburdening.

- Scenario Modeling: Test various maintenance scenarios and their potential impacts before implementation. This proactive approach helps in mitigating risks and optimizing scheduling.

- Collaborative Planning: Enable collaboration among various departments and teams by providing a centralized platform for sharing insights, updates, and adjustments to the maintenance schedule.

- Data-Backed Decisions: Make informed decisions based on data-driven insights, historical performance, and predictive analytics, ultimately enhancing the efficiency and effectiveness of maintenance planning.

Together, mobile work order and visual planning solutions can help to improve asset maintenance and operations management in mining by:

- Improving the efficiency and accuracy of maintenance work: Technicians can access work orders and other relevant information on their mobile devices, which can help them complete tasks more quickly and accurately.

- Improving communication between technicians and other stakeholders: Technicians can communicate with supervisors, engineers, and other stakeholders through the mobile work order and visual planner applications. This helps ensure everyone is on the same page and that maintenance work is completed on time and within budget.

- Improving the visibility of maintenance activities: The mobile work order and visual planner applications provide a central repository for all maintenance data. This helps improve visibility into maintenance activities and identify potential problems.

Innovapptive’s Asset Maintenance and Operations Solutions For Mining

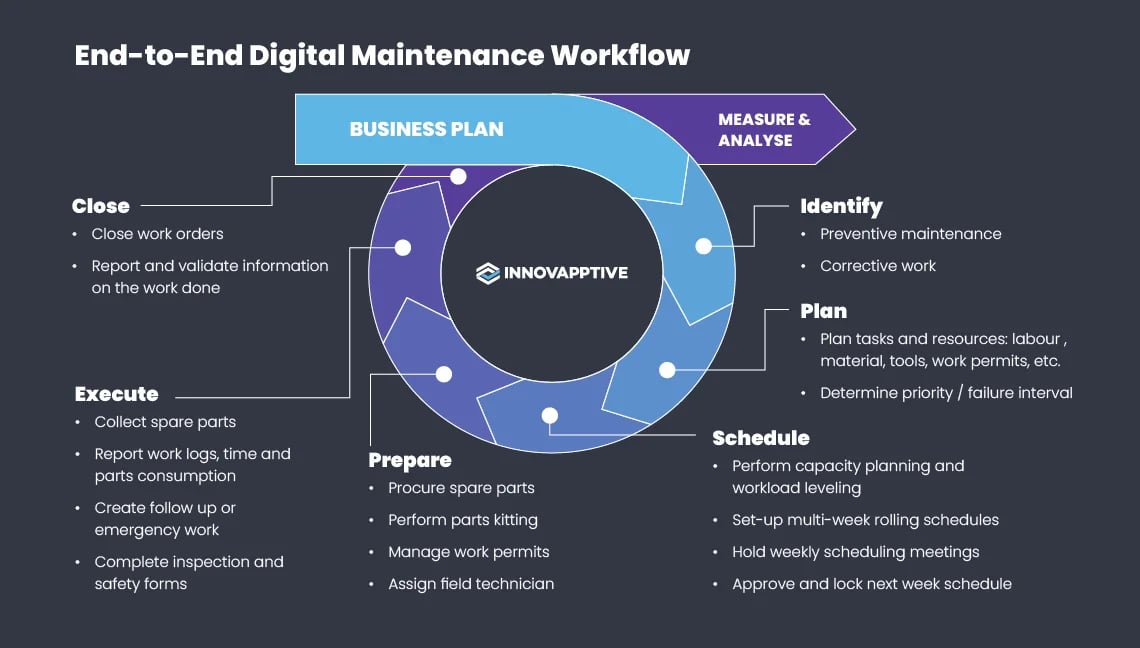

Incorporating mobile work order systems and visual planning tools into mining operations management transforms the teams that handle maintenance tasks, optimize resource utilization, and ensure the longevity of mining equipment. Innovapptive’s Visual Planner digitalizes maintenance work order planning and scheduling. Mining companies can achieve maximum efficiency by eliminating paper-based processes, optimizing resource utilization, and maximizing the scoping, organizing, and timing of simple repairs to complex turnarounds — even emergency ones.

Visual Planner extends asset lifespan and reliability, minimizes asset breakdowns, boosts safety compliance, and improves profitability. It’s the only embedded SAP tool designed to support EPRI best practices guidelines.

Innovapptive’s mWorkOrder, meanwhile, supports preventive maintenance strategies that let mining maintenance teams move away from the inefficient and reactive “run-to-fail” approach. mWorkOrder increases communication between field technicians and supervisors. The solution helps:

- Reduce unplanned downtime: Any downtime is money not being made. Unplanned downtime strains revenue streams and puts customer relationships at risk.

- Decrease operational costs: Maintenance costs alone can account for a significant part of a company’s annual budget, work order management tools can deliver cost savings in the long term because the cost of deferred maintenance can be high.

- Eliminate paperwork and streamline workflows: Paperwork is a problem in plant maintenance today because of the recording and maintenance issues, so a digital transformation would always help to do a better job in record keeping and data analysis.

- Extend and improve asset life and reliability: With preventive and predictive maintenance in place, the assets would perform better and would be more efficient.

mWorkOrder can be used at any mining operation – open pit, surface, subsurface, or in-situ – to increase the uptime of extraction, handling, and processing equipment.

Reimagine Your Mining Asset Maintenance and Operations Management With Innovapptive

Now is the time for mining organizations to capitalize on the opportunities that digital transformation and automation provide to improve bottom lines, eliminate inefficiencies, increase compliance, reduce asset downtime, and boost employee morale. Innovapptive’s configurable mWorkOrder and Visual Planner solutions provide the answer for mining companies looking to tackle asset management challenges, generate value from their assets, and stay ahead of their competitors. View a short introductory video here.

Schedule a free demo today to learn how these two solutions can make your asset maintenance and operations faster and more efficient. Or, call 888-464-6668 to speak to one of our mining industry experts today.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”