How Visual Planner Helps With Maintenance Planning

“Proper planning and preparation prevents poor performance.”

Stephen Keague, author

A plant maintenance planner occupies an important position on the org chart. Without one, turnarounds, shutdowns and equipment repairs would be done on a haphazard basis putting assets, production and revenues at risk.

What is Maintenance Planning?

Reliable Plant defines maintenance planning as an:

… end-to-end process that identifies and addresses any possible issues ahead of time. This involves identifying the parts and tools necessary for jobs and making sure they're available and laid out in the appropriate areas, having a planner write out instructions on how to complete a job, and even determining and gathering the necessary parts and/or tools before a job is assigned.

Maintenance planners ensure maintenance projects and work orders follow a logical, efficient and productive outline. This plan enables technicians and contractors to complete tasks in the most practical and economical manner possible to preserve and enhance asset reliability, production output and revenue flow.

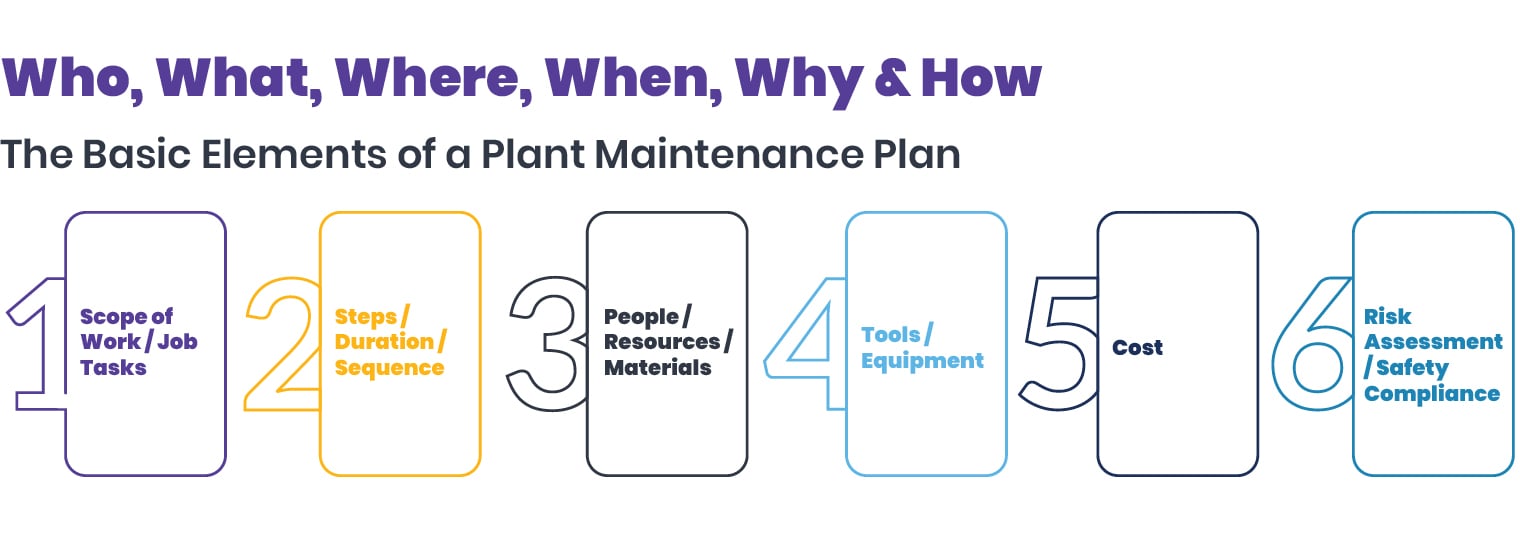

A maintenance planner specifies:

- Project rationale

- Work scope and order

- Parts and materials required

- Tools needed

- Number of technicians or contractors

- Total work hours

- How the work ought to be done

A maintenance planner has responsibility for:

- Ordering parts

- Staging materials

- Managing vendor lists

- Quality control

Maintenance planners utilize numerous tools and information in their day-to-day activities. These include equipment histories, work order systems and metrics. The more complete these are, the more effective and efficient planners will be in their job. If any or all of these become roadblocks, a planner’s productivity suffers as does the value and usefulness of maintenance projects on which he or she is working.

That’s not all.

Poorly coordinated maintenance planning wastes precious time and resources, particularly in an emergency. It creates problems such as:

- No set or clear priorities

- Confusing or conflicting work orders

- Lack of needed parts

- Unnecessary travel

- Project delays

- Incomplete repairs

- Risk of equipment failure

- Frustration

Challenges to Efficient Maintenance Planning

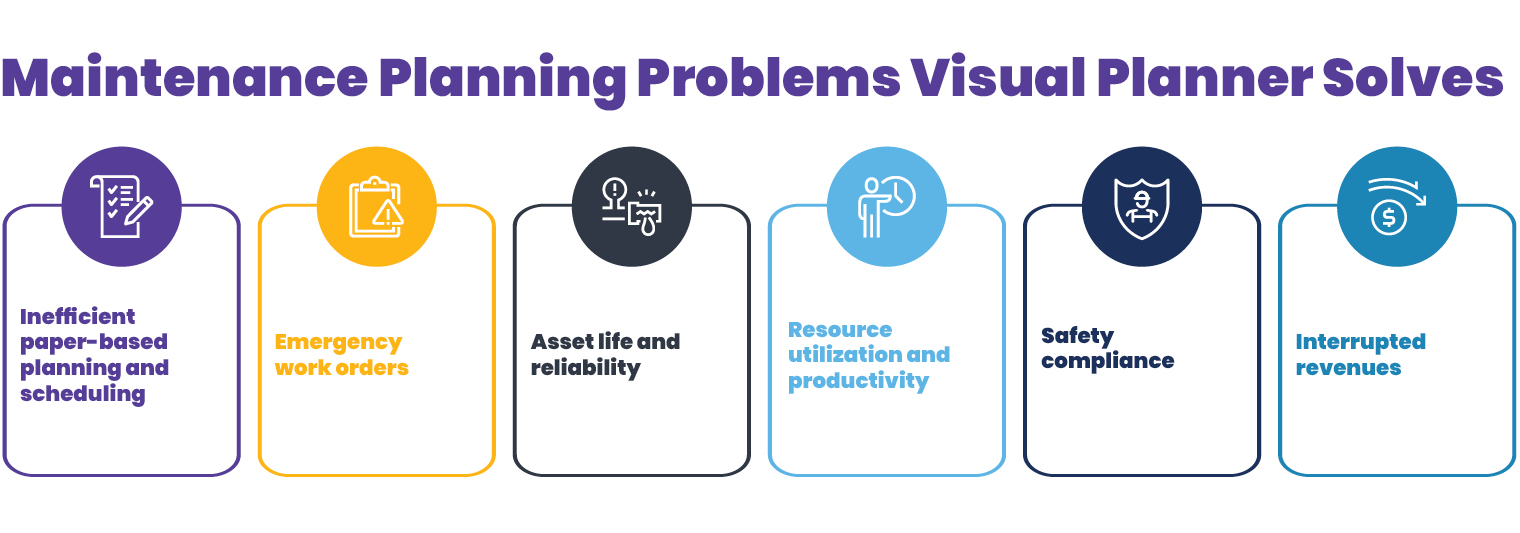

Asset-intensive industries such as oil and gas, utilities, mining and metals, manufacturing and rail face daily challenges in optimally planning and scheduling work orders— especially emergency ones. A paper-based planning and work order process compounds — and often magnifies — these challenges, causing wasteful delays.

A paper-based planning and work order process offers no real-time visibility into resource and asset availability. It doesn’t give a timely view of scheduled work orders and backlogs. Maintenance planners are left to the mercy of a slow-moving paper trail.

Planners can only get information as paper forms reach them or someone manually uploads data into an ERP like SAP. This time delay worsens responses during an emergency maintenance situation, leading to unscheduled downtime or an otherwise preventable safety or environmental incident that often leads to costly fines or penalties.

Poor maintenance planning negatively affects asset lifespan and reliability. Equipment is more prone to failure if it isn't properly maintained in a timely manner.

Aging assets are the major cause of unplanned downtime. A recent study found 70% of industrial plants had no firm idea of when their equipment is due for routine maintenance, upgrade or replacement. This lack of awareness places plants in a reactive maintenance mode rather than a more effective, proactive one. It increases their risk of equipment failure and downtime.

Visual Planner Offers a Solution to Your Maintenance Planning Problems

Innovapptive has introduced a digital maintenance and planning solution that helps plants organize and chart future turnaround and equipment repair plans, and schedule and allocate needed resources for routine or emergency work orders. Visual Planner works in conjunction with mWorkOrder to give planners and schedulers greater flexibility and control over this critical stage of the plant maintenance process.

Visual Planner runs on tablet devices, mobile phones and desktops. The solution works in online and offline modes. It also integrates with SAP.

With an intuitive, easy-to-use dashboard, planners and schedulers can:

- Plan job scopes

- View and update crew availability before assigning work orders

- Assign resources to work orders with a simple click

- Check parts availability and perform kitting

Visual Planner ensures smooth operations in case of an emergency stoppage. Planners and schedulers don’t suffer from delays stemming from paper-based processes. Real-time visibility means faster response times in situations where time is critically important, from production, customer service, revenue and safety standpoints.

Want to Learn More about Visual Planner?

Innovapptive’s Visual Planner solution, part of the company’s Connected Worker enterprise asset management platform, digitalizes maintenance work order planning and execution. Optimize resource utilization, extend asset lifespans and reliability, minimize asset breakdowns, boost safety compliance, and improve profitability. Schedule a free Visual Planner demo today or call us at 844-464-6668.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”