Mining Safety Hazard Mitigation Using a Mobile Work Order Solution

Digital transformation in mining is becoming an ever-more important topic, especially when it comes to safety. Inefficient safety inspection processes in this sector are not just a minor inconvenience; they represent a disaster waiting to happen.

Why Efficient Inspection is Crucial in Miningp

- Safety First: The mining industry is inherently hazardous. Regular and thorough inspections are critical to ensure the safety of the workforce and to prevent catastrophic accidents. An inefficient inspection process can overlook potential hazards, leading to severe consequences.

- Equipment Reliability: Mining relies heavily on specialized machinery. Inefficient inspections can result in unnoticed wear and tear, leading to equipment failure. Such breakdowns not only cause costly downtime resulting in lost tonnage, but also can be dangerous for workers.

- Environmental Impact: Mining activities have a significant impact on the environment. Efficient inspection processes are essential to ensure compliance with environmental regulations and to minimize the ecological footprint of mining operations.

- Quality Control: The quality of the extracted materials is paramount. Inefficient inspection processes might lead to subpar material quality, affecting the market value and credibility of the mining operation.

- Economic Implications: Inefficient inspections lead to increased operational costs due to unexpected downtime, equipment repairs, and potential legal liabilities arising from non-compliance with safety and environmental regulations.

The Role of Mobile Work Order Solutions

In addressing the inefficiencies of traditional inspection processes, mobile work order solutions emerge as a game-changer for the mining industry. These solutions offer several advantages:

- Real-time Data Access and Reporting: Mobile solutions allow inspectors to access and report data in real time. This immediacy ensures that any issues are identified and addressed promptly, reducing the risk of equipment failure or safety hazards.

- Enhanced Accuracy and Reliability: With pre-defined checklists and the ability to include photographic evidence, mobile work order solutions enhance the accuracy and reliability of inspections.

- Improved Compliance Tracking: These solutions make it easier to track compliance with safety and environmental regulations, ensuring that the mining operation adheres to legal standards.

- Reduced Paperwork and Administrative Burden: By digitizing the inspection process, mobile solutions reduce the paperwork and administrative overhead, freeing up time for more thorough inspections.

- Data Analytics for Continuous Improvement: The data collected through mobile solutions can be analyzed to identify trends, predict potential equipment failures, and continuously improve the inspection process.

The mining industry cannot afford to overlook the importance of efficient inspection processes. Inefficient inspections are more than just an operational hiccup; they are a disaster waiting to happen, with implications for safety, environmental stewardship, and economic viability. Mobile work order solutions offer a practical and innovative approach to revolutionizing inspection processes, making them more efficient, accurate, and compliant. In the high-stakes arena of mining, embracing these technological solutions is not just beneficial; it is essential for sustainable and safe operations.

Desirable Features of Mobile Work Order Management

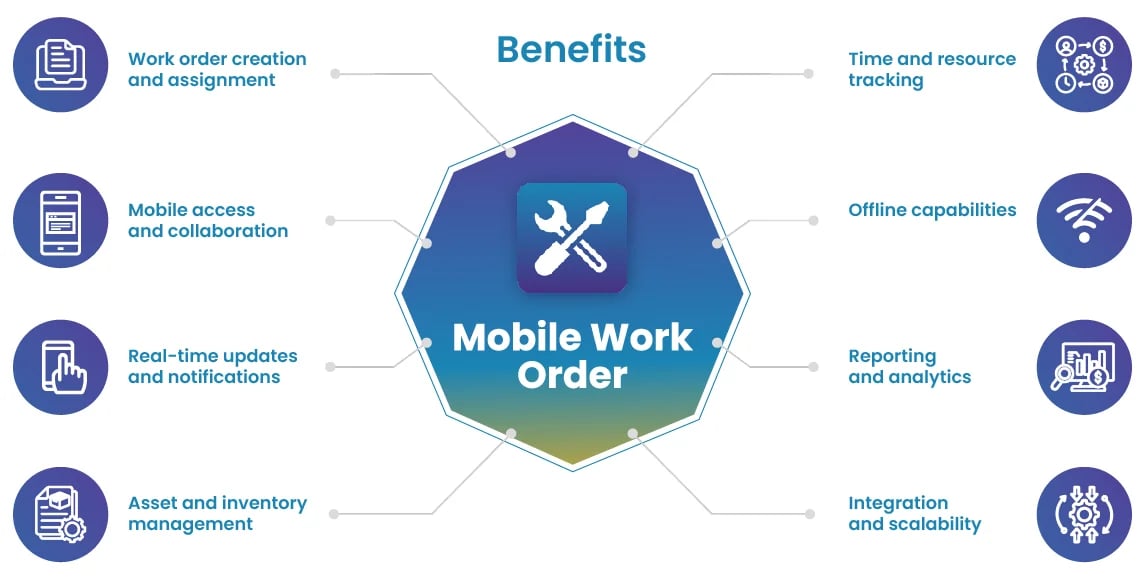

Mobile work order management software is a powerful tool that streamlines and automates the management of work orders and enables organizations to efficiently create, assign, track, and complete field services.

Here's an overview of the key features and benefits of a desirable mobile work order software.

Features:

- Eliminates error-prone paper count sheets and Excel spreadsheets

- Supports Android, iOS, and Windows applications

- Runs on tablet devices, mobiles, and desktops

- Utilizes native mobile device capabilities such as GPS, camera, and push notifications

- Easy configuration and customization using no-code/low-code technology

- Intuitive, easy-to-follow workflows with touchscreens

- Works in offline and online modes

- Role-based mobile screens

- Integrated with industry-standard peripheral scanners

- Compatible with Bluetooth devices

mWorkOrder: Redefining Inspection With Intelligent Technology

mWorkOrder, a pivotal component of Innovapptive’s Mobile Work Order Management Software, is transforming the landscape of inspection processes with its cutting-edge technology. This mobile application seamlessly integrates back-end work order management with field-based technicians, thereby revolutionizing how work orders are assigned, tracked, resolved, and reported. Key features and benefits include:

- Enhanced Productivity: By mobilizing the workforce and automating work order processes, mWorkOrder bridges informational gaps, leading to increased productivity and efficiency in tackling work orders.

- Accuracy and Equipment Longevity: The application brings pinpoint accuracy to maintenance measurements and readings, extending the life of critical equipment. It also facilitates proactive maintenance to ensure safety and compliance across the enterprise.

- Data-Driven Decision Making: mWorkOrder enables the collection and analysis of performance and business data, helping in identifying energy waste and reducing operational costs.

- Offline Capability: One of the remarkable features of mWorkOrder is its ability to function both online and offline. This allows remote workers to enter asset data from equipment locations, even in areas with intermittent or no internet access, ensuring uninterrupted workflow.

- Rich Media Integration: The app supports the capture of photos, videos, and documents, adding a rich layer of detail to work orders and notifications. This feature significantly enhances the quality of the data collected during inspections.

- GIS Integration: By integrating geospatial systems, mWorkOrder promotes efficient processes and better decision-making through an understanding of location and spatial relationships.

Digital Transformation in Mining with Innovapptive’s mWorkOrder

Take the efficiency and precision of your inspection processes in the mining sector to the next level with Innovapptive's mWorkOrder. This solution offers technicians immediate, anywhere access to crucial information, bolstering both safety and accuracy. With its online and offline capabilities, mWorkOrder ensures continuous, dependable asset support, leading to improved reliability and performance throughout your mining operations.

Learn how Innovapptive's Connected Worker app, mWorkOrder, can transform your inspection routines through state-of-the-art mobile work management. Watch our detailed video for insights and schedule a free demo to witness the benefits firsthand. Contact us at 844-464-6668 or click here for more information.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”