7 Plant Challenges Digital Inspections Can Solve

Inspections play a pivotal role in maintaining operational integrity, safety, and compliance in industrial plants. These inspections involve on-site assessments of equipment, processes, and facilities to ensure that they meet industry standards and regulatory requirements. While the benefits of field inspections are undeniable, they are not without their challenges, especially in the complex and dynamic environment of industrial plants. In this article, we delve into the key challenges that professionals face and explore how digital inspections can offer a potential solution to overcome these hurdles.

Challenge 1: Hazardous Work Environment

Industrial plants are often home to hazardous materials, high temperatures, heavy machinery, and other risk factors that can pose serious threats to the health and safety of inspectors. Navigating these environments requires specialized training, personal protective equipment (PPE), and a keen understanding of safety protocols. The challenge lies in ensuring that inspectors are adequately protected while conducting thorough inspections. Solutions include continuous safety training, the use of advanced PPE, and the implementation of clear emergency response procedures.

Challenge 2: Limited Access to Certain Areas

Some areas within industrial plants may be difficult to access due to their location, height, or confinement. Inspectors might encounter challenges when trying to reach these areas to assess equipment or systems. This limitation can hinder the comprehensive evaluation of all plant components. Employing technologies such as drones or remote-controlled cameras can help inspectors access hard-to-reach areas and capture visual data, enabling a more thorough inspection process.

Challenge 3: Aging Infrastructure

Many industrial plants operate with aging infrastructure, which can increase the likelihood of equipment failures, leaks, and other issues. Conducting inspections in such environments requires a focused approach to identify signs of wear, corrosion, and deterioration. The challenge is to differentiate between normal wear and critical issues that demand immediate attention. Regular and proactive inspections, combined with condition monitoring technologies, can help address this challenge by identifying deterioration before it escalates.

Challenge 4: Time Constraints

Industrial plants often operate around the clock to maintain production schedules. This leaves limited windows for conducting inspections without disrupting operations. Inspectors must work efficiently to gather the required data within these time constraints. Proper scheduling, coordination with plant management, and the use of mobile inspection tools can help maximize the effectiveness of inspections while minimizing downtime.

Challenge 5: Data Overload and Analysis

Modern industrial plants generate a massive amount of data from sensors, meters, and monitoring systems. Inspectors must sift through this data to identify trends, anomalies, and potential areas of concern. The challenge lies in managing and analyzing this influx of data effectively. Utilizing data analytics tools and software can assist inspectors in identifying patterns that might indicate impending failures or deviations from normal operating conditions.

Challenge 6: Documentation and Reporting

Accurate and detailed documentation is crucial for tracking inspection findings, recommended actions, and corrective measures taken. However, the challenge lies in compiling and organizing the vast amount of information gathered during inspections into coherent and actionable reports. Digital inspection platforms and reporting tools can streamline this process by allowing inspectors to input data directly into standardized templates, ensuring consistency and completeness in documentation.

Challenge 7: Evolving Regulatory Requirements

Regulations governing industrial plants are subject to change as safety standards and environmental concerns evolve. Staying updated with these regulatory changes and ensuring that inspections align with the latest requirements can be challenging. Engaging with regulatory authorities, subscribing to industry newsletters, and participating in professional networks can help inspectors stay informed about the latest developments.

Legacy Inspection Processes Fail to Meet These Challenges

Many industrial plants and manufacturing facilities are having difficulty with the seven challenges listed above. Unfortunately, their inspection process is what’s holding them back. Why? Because they employ outdated paper forms and checklists. This process frequently causes more problems than it solves, such as:

- Paper forms are difficult to change when regulatory or business needs shift

- Once reviewed, these paper forms are filed, and the valuable information they contain becomes difficult to access and analyze

- If entered into the back-office system, it means doing the job twice, taking the tech or operator away from their primary duties

- Dozens of pages for hundreds of checkpoints are archived without detailed analysis

- Delay in triggering a corrective action once a potential issue is detected during inspections

Is there a solution that can overcome the seven problems listed at the beginning of this blog and make for more efficient field inspections than paper forms and checklists? Yes!

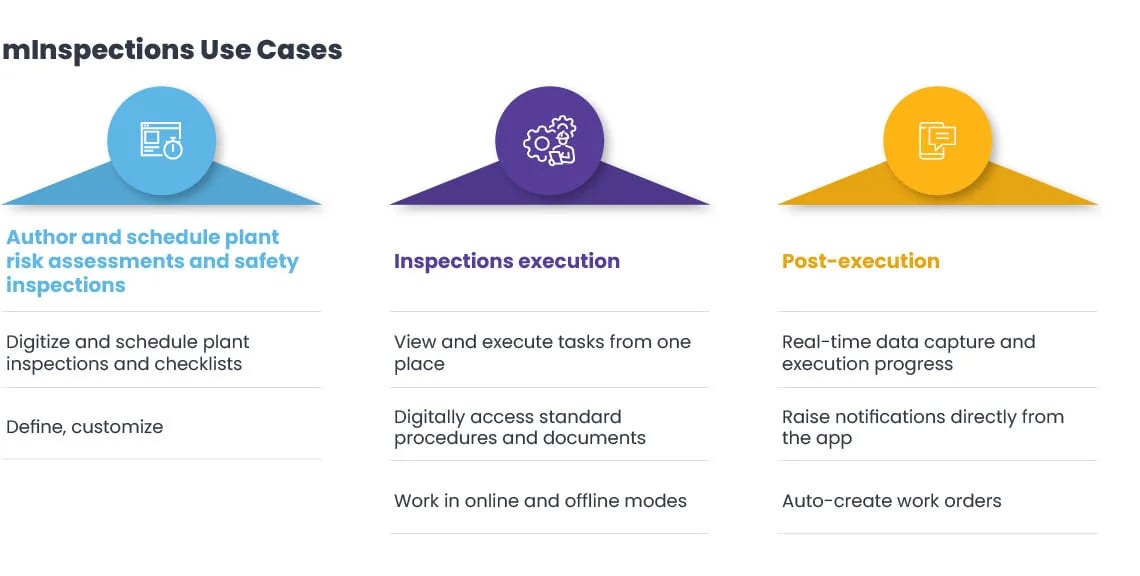

Move to a Digital Inspections Program with Innovapptive’s mInspections

mInspections is a completely digital, highly agile, dynamic, and code-free inspection SaaS platform. No paper, clipboards, or binders are required.

Here’s how mInspections works. In the office, the manager or supervisor can plan, schedule, and issue an inspection, authoring a digital form to meet the company’s business needs, in less than 30 minutes thanks to Innovapptive’s patented Rapid Application Configuration Engine (RACETM). RACE permits a user to quickly and easily create, edit, and deploy digital forms, even if the user has little or no coding, technical knowledge, or experience.

Moving into the field, a technician completes the inspection or round in a 100% digital manner – no paper or manual data entry is required. The technician instead uses the convenient portability of a mobile device, such as a smartphone or tablet, to perform the inspection or round in the field. If needed, data recording can be made by a drone for limited access areas.

Data is uploaded automatically to the Cloud database for reporting and analytics. Managers and supervisors may follow the progress in real time, gaining valuable visibility into conditions at the plant and a head start on making knowledge-based decisions on potential remedial action to take if needed.

What Sets Innovapptive’s mInspections Apart?

Conditional Logics in Checklists: Adaptable checklists equipped with dynamic conditional logic for comprehensive, real-time responsive inspections.

Foolproof Audit Data Collection: Enhances transparency with accurate, automated data collection and a robust, reliable audit trail.

Configurable PDF Reports: Quickly create detailed, color-coded reports for easy data interpretation and immediate insights.

Context-Driven Chat Collaboration: Features enabling swift, context-aware chat collaborations for instant issue response and resolution.

IoT and PI Systems Integration: Ensures informed decisions by aligning field and digital data through IoT and PI systems compatibility.

Observation Dashboards: Offers quick, informed decisions with consolidated data views and actionable insights via intuitive dashboards.

ERP Integration: Seamlessly integrates with ERP work orders, especially alongside Innovapptive’s mWorkOrder, for real-time data and enhanced metrics reliability.

Ready to Overcome Your Inspections Challenges? Here’s How

Visit our dedicated mInspections microsite to discover more about the benefits of moving from a paper-based process to an ERP-integrated solution. Or, watch a short, 3-minute video illustrating mInspections’ many benefits. Ready to make a move? Schedule a free demo today or call 844-464-6668 to speak to one of Innovapptive’s experts.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”