What Differentiates Innovapptive's Mobile Operator Rounds

In today's competitive industrial world, plants must routinely conduct operator rounds to identify potential equipment malfunctions and safety concerns. These inspections, when carried out diligently, help reduce unexpected equipment breakdowns and enhance workplace safety. But what if these routine checks could be made even more efficient and precise? Enter Innovapptive's mobile operator rounds solution. Rather than relying on manual data gathering and sharing, Innovapptive empowers operators to conduct their daily rounds using mobile devices, delivering real-time information that bridges the gap between operations and maintenance.

The Importance of Mobile Operator Rounds

Mobile operator rounds have emerged as game-changers, replacing traditional paper-based checklists with real-time, digital data collection. Operators, equipped with mobile devices, can swiftly identify equipment anomalies, ensuring timely maintenance. This proactive approach not only reduces downtime but also enhances safety by quickly pinpointing potential hazards. By seamlessly integrating operations and maintenance, mobile rounds facilitate data-driven decisions, ensuring optimum plant performance and a safer work environment. Embracing this digital shift is essential for industrial plants aiming for operational excellence.

Features that Set Innovapptive’s Mobile Operator Rounds Apart

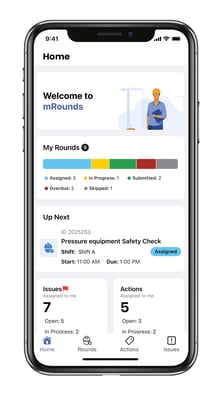

Innovapptive, a digital transformation and connected worker solution leader, has developed Mobile Operator Rounds, a digital solution that replaces error-prone manual checklists with an efficient electronic process. Inside and outside operators at oil & gas, chemical, mining, utility, and manufacturing facilities can access digital forms on their devices to conduct rounds and inspections.

Here’s what makes Innovapptive's digital operator rounds superior:

Dynamic Route Optimization: In expansive industrial plants, moving between various stop points can be daunting. Innovapptive’s solution offers route optimization, ensuring quick transitions from one point to another, thus minimizing time wastage and fatigue.

Conditional Logics within Round Checklists: Digital checklists in Innovapptive's platform are far from static. They incorporate dynamic conditional logic where subsequent checklist items adjust based on prior responses. This flexibility ensures every potential scenario is covered, leaving no stone unturned.

Data Collection for Foolproof Audit: Say goodbye to the days of tedious manual data entry. Innovapptive's rounds ensure automatic data integration into handover reports, guaranteeing data accuracy and leaving minimal room for human error. The result? A flawless audit trail.

Synergy between Operations and Maintenance: Effective communication between operations and maintenance teams is vital. Innovapptive facilitates this through real-time data sharing, fostering proactive maintenance and streamlined operations.

Context-Driven Chat and Collaboration: These digital rounds go beyond mere data collection. The platform promotes immediate collaboration, allowing operators to connect swiftly with relevant teams or supervisors when irregularities arise.

Integration with IoT and PI Systems: With the rise of IoT devices and Performance Indicators (PI) systems in industrial settings, it’s imperative for operator rounds to align with these technological advancements. Innovapptive’s solution does just that, ensuring on-field data complements digital insights, paving the way for smarter decisions.

Automated Shift Handover Reports: The seamless transition between shifts is crucial for continuous operations. With Innovapptive, data from one shift can be effortlessly passed on to the next, ensuring consistency and minimizing downtime.

Observation Dashboards: A quick, comprehensive overview can make all the difference in decision-making. Innovapptive's digital rounds come equipped with observation dashboards, allowing supervisors to instantly grasp the operational status and act promptly when necessary.

In Conclusion

The digital evolution of operator rounds with Innovapptive isn't about sidelining human skills but amplifying them. By harnessing digital tools, operators can perform their roles more efficiently, communicate seamlessly, and contribute valuable insights that drive the industry into the future. As industrial landscapes progress, adopting these digital transformations is less about merely keeping pace and more about leading the way.

Discover Why Innovapptive Should Be Your Partner of Choice

Schedule a free demo today or call 844-464-6668 to speak to one of Innovapptive’s experts about how our Mobile Operator Rounds can make your operations and maintenance more proactive, agile, collaborative, and safer through a single solution.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”