3 Digital Trends Topping 2019 in Field Workforce Management

Managing your field workforce effectively isn’t as easy it sounds. Advances in technology make it much more feasible and achievable. The evolution of Cloud computing and mobility have given rise to tools enabling your employees to collaborate, regardless of locale, producing a more evolved and engaged workforce.

As we step into 2019, here are the top 3 trends making impressive impacts on field workforce management.

1. Improved Enterprise Asset Management with IoT

Asset Management is one of the biggest areas where

Fortunately, IoT presents many new ways of servicing customers with automation, optimization, asset performance management, and the creation of new revenue models. Field service organizations have evolved alongside IoT. Solutions equipped with IoT sensors can pinpoint problems before they become severe. Your techs can identify issues and resolve them before they happen. When a part or system isn’t working correctly, IoT sensors detect and notify the necessary departments then sensors send requests to replace or repair the faulty piece(s) of equipment before a service call is made by the customer.

Field service organizations are heavily investing in IoT to increase growth and maximize productivity. Speculations project that over 60% of manufacturing organizations are expected to apply IoT to products over the next 5 years. They are also hoping to apply over $250 billion in IoT by 2020. IoT Solutions enable your field workforce to access relevant information and increases connectivity within the field service operation while fostering a predictive model to address customer concerns.

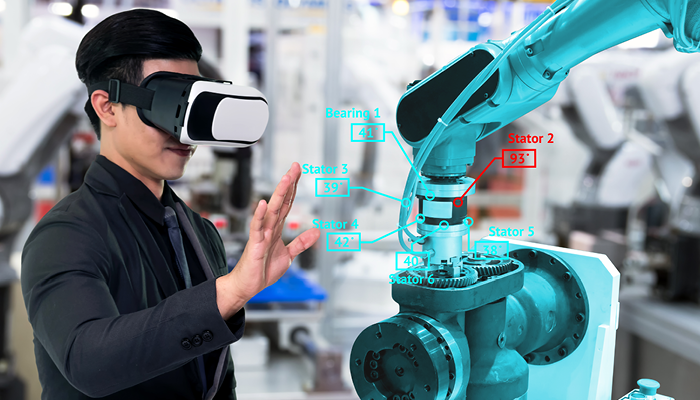

2. Immersive Experience with AR and VR

Augmented reality (AR) and virtual reality (VR) are two immersive technologies gathering speed across a multitude of industries at the end of 2018 and as 2019 kicks off. Both have incredible potential to change the way organizations, and their users, collaborate to solve issues effectively.

In the next five years, much focus will be on mixed reality (combination of AR and VR), where the user will able to interact with digital and real-world objects while being present in the physical world. One such industry seeing mixed reality (the combination of AR/VR) is manufacturing. The use of mixed reality in manufacturing allows companies to train new workers more efficiently, reducing time spent training by over 30% and reducing documentation time by at least 75%.

3. No Longer a Buzzword – Mobility is a Necessity

When a multinational tech conglomerate like Cisco projects the number of connected devices to exceed 50 billion by 2020, organizations listen.

Businesses are adopting mobile solutions to simplify and streamline operations - making them more effective and less cumbersome. Organizations without mobile-first strategies will be left behind their competitors. Today, organizations need real-time insight into the daily activities of the office and field, creating more accurate projections and planning in operations and, inevitably, achieving goals.

In field workforce management, mobility is more than just managing your workers’ schedules with mobile devices. In addition, mobility empowers your field workforce to access the right information at the right time in the right context. Mobility helps field service organizations resolve issues faster, maximize employee productivity, and improve customer service.

Answering Technology Trends

With adoptions of new technologies like IoT, mixed reality, and mobility, Customer behaviors are shifting. They are expecting to be met on their “turf”, rather than the customer come to you. To meet the demands of such transitions to technologies like virtual meetings (in lieu of face to face) and mobile workstations rather desktops, Innovapptive is empowering enterprises to consume digital technologies in a few clicks. With a business solution framework that accelerates your time to market (responsive to

Innovapptive’s mobile EAM platform,

Learn how Australia’s largest utility company utilizes Innovapptive’s

Want to Discover More?

Innovapptive – a Connected Worker Platform provider – has a simple mission: “Connect and create conversations between people, machinery and work processes while improving people’s lives.” Innovapptive offers the only Connected Worker Platform that digitizes the last mile of your front-line workers into SAP and IBM (watch a short video here). We’d like to show how our Connected Worker Platform and related applications can help you successfully start and complete your journey to more efficient, safe and productive plant operations. Schedule a free demo today by calling 844-464-6668 or or by clicking here.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”