Industry 4.0: Mobility in Manufacturing

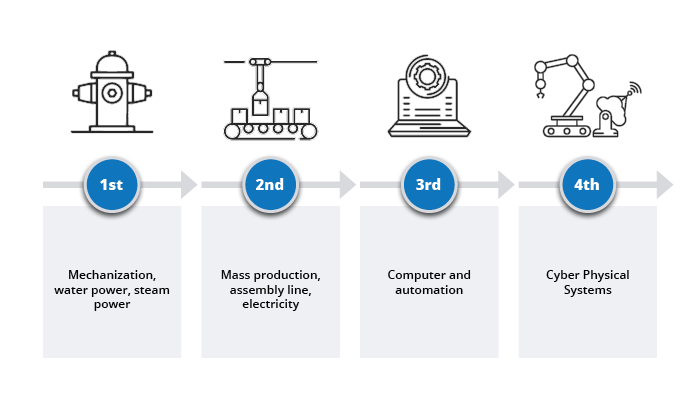

Industry 4.0 is driving a transformative wave in manufacturing with data exchange and automation through technologies like IoT, cloud computing, cognitive computing, and cyber-physical systems. Mobile solutions are now integral to this transformation, creating “smart factories” and enhancing operational efficiency in the manufacturing sector. Mobility in manufacturing is not only streamlining processes but also enabling manufacturers to gain a competitive edge in the age of Industry 4.0.

How Mobile Solutions Drive Industry 4.0 in Manufacturing

Although the adoption of mobile technology was initially slow, manufacturers are increasingly aware of the substantial benefits other industries have achieved through mobile solutions. With Industry 4.0's focus on connected systems, mobility allows manufacturing operations to stay closely integrated, enabling real-time data exchange and seamless collaboration among machines and personnel. Mobile solutions in manufacturing enhance productivity, reduce downtime, and offer a more connected, efficient working environment.

Top Benefits of Mobility in Manufacturing Operations

-

Portability

Mobile apps are designed for on-the-go access. With the right mobile solution, employees can access information, checklists, or order details without needing to return to a fixed station. Tablets and mobile devices allow workers to perform quality checks, flag issues, and instantly update job statuses. This mobility in manufacturing saves time and reduces delays. -

Real-Time Problem Solving

In a fast-paced industry, the ability to identify and resolve issues in real time is crucial. Rather than relying on predictions or historical trends, manufacturing teams need tools that alert them to issues as they occur. With Innovapptive’s mInventory solution, staff and management receive instant alerts, enabling rapid responses and proactive decision-making, which ultimately strengthens customer relationships and improves outcomes. -

Increased Worker Productivity

Mobile tablets boost productivity by enabling workers to perform tasks away from stationary workstations. With modern manufacturing employees already familiar with mobile technology, introducing mobile solutions reduces training time and improves workflow efficiency. Workers can complete tasks faster and more effectively, enhancing overall productivity. -

Precision Monitoring

GPS-enabled mobile devices provide manufacturing teams with real-time logistics insights, helping them identify inefficiencies in freight management and logistics. Instant status updates allow leaders to track orders, locate raw materials, and monitor incoming goods. For sales teams, real-time inventory access boosts efficiency and strengthens customer interactions.

Why Manufacturing Needs Mobile Device Management (MDM)

As mobility in manufacturing continues to grow, many companies now provide mobile devices to employees instead of allowing personal devices (BYOD) to ensure data security and control. Innovapptive helps companies address mobile device management (MDM) concerns, such as data theft, device misuse, and productivity loss due to distractions. With Innovapptive’s solutions, companies can secure their data while maximizing the operational benefits of mobile technology in manufacturing.

Operational Benefits of Mobility

Implementing mobile solutions in manufacturing offers numerous operational benefits:

- Increased Productivity – Enables teams to complete tasks faster and more accurately.

- Cost Reduction – Streamlines operations, reducing overhead and waste.

- Faster Access to Critical Information – Provides real-time data to employees at all levels.

- Improved Collaboration – Facilitates instant communication across the team.

- Higher ROI – Maximizes asset usage and resource efficiency.

- Sales Growth – Mobile access to inventory boosts sales potential.

- Competitive Advantage – Keeps manufacturers on the leading edge of innovation.

Innovapptive’s mInventory: A Mobile Solution for Manufacturing Efficiency

Innovapptive offers mInventory, a Mobile Inventory and Warehouse Management Application that allows warehouse employees to perform day-to-day inventory transactions through smartphones, tablets, RF scanners, and laptops, integrating seamlessly with SAP. mInventory optimizes supply chain operations and ensures accurate, real-time data across multiple devices, whether online or offline. The application enables manufacturing teams to:

- Access real-time inventory data across plants, warehouses, and storage locations.

- Quickly perform physical and cycle counts to achieve high data accuracy.

- Reduce inventory discrepancies and improve customer satisfaction.

- Eliminate downstream issues in inventory and invoicing, ensuring smoother operations.

Take Your Manufacturing Operations to the Next Level

Discover how Innovapptive’s mInventory can transform your manufacturing processes with real-time, mobile-enabled inventory management. Book a demo of Innovapptive’s mInventory solution to see how mobility can drive your Industry 4.0 success, or speak with an Innovapptive solution expert today.

See It In Action

Schedule a personalized demo to see how our solutions can help your business thrive.

- 29-09-2025

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal...

- 20-08-2025

Building the future of Industrial Operations with Innovapptive and AWS

Most manufacturers have already gone digital. Yet business outcomes haven’t moved in step. Many...

- 22-04-2025

The $3.6B Unlock: Solving the Chemical Industry’s Labor Crisis and EBITDA Pressure in One Move

“Constraints don’t slow innovation—they force it.”