-

Platform

The #1 Platform Driving Frontline-First Digital TransformationConnected Worker PlatformLearn More

-

Product

Operations SuiteMaintenance SuiteWarehouse SuiteContinuous Improvement Suite

-

Solutions

By Business ChallengeBy Industry

- Resources

- Company

- Contact Us

Find What You Need, Instantly!

Your Ultimate Guide to Connected Worker

In the rapidly evolving industrial landscape, maximizing plant efficiency and ensuring optimal maintenance are more urgent than ever. Manufacturers, ...

- 20-09-2021

How Mobile Operator Rounds Reduce Manufacturing Downtime and Improve Plant Safety

American manufacturing plants are making do with increasingly older equipment, with a high percentage of production machines averaging 20 or more years of active operational service. Relying on aging ...

- 23-08-2021

5 Factors to Consider When Shopping for a Mobile Warehouse Operations Solution

Warehouse management technology has revolutionized many aspects of warehouse operations. But often these fancy back-office systems leave frontline warehouse workers in the lurch by forcing them to man...

- 13-08-2021

How Risk-Based Maintenance Optimizes Plant Maintenance

Introduction: Prioritize Critical Assets with Risk-Based Maintenance In industrial environments, maintenance teams must prevent unexpected equipment failures while ensuring operational continuity and ...

- 30-07-2021

When You Should Consider a Condition-Based Maintenance Approach

Traditional maintenance strategies like time-based maintenance or risk-based maintenance often lead to unnecessary downtime and inflated costs. This is where condition-based maintenance (CBM) becomes ...

- 22-07-2021

What is a Connected Worker?

Industrial operations are undergoing rapid digital transformation, yet a critical gap persists: frontline workers often lack access to the advanced tools and technologies available to back-office staf...

- 09-07-2021

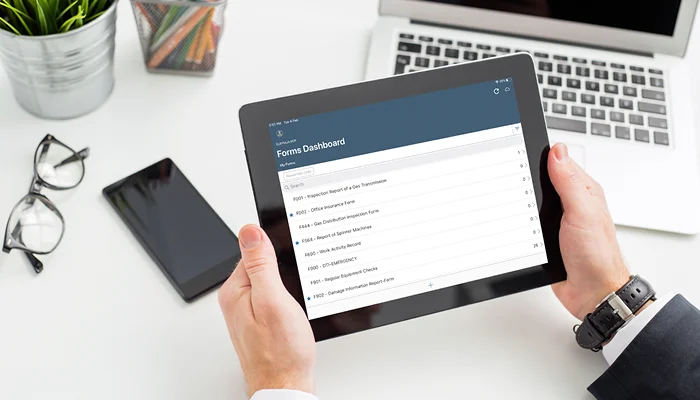

How Configurable Digital Forms Transform Maintenance and Operations

The Information Age is more than 50 years old but you wouldn’t know it looking around a lot of industrial organizations in 2021.

- 09-07-2021

Achieving Optimal Opportunistic Maintenance with a Mobile EAM Solution

Time-based and condition-based maintenance strategies are effective in enhancing equipment reliability, but they can come at high downtime costs, requiring the shutdown of equipment or entire producti...

- 30-06-2021

Utility Speeds Meter Activations Using Mobile Work Order Management Solution

One of the biggest drivers of digital transformation is being able to accomplish what was impossible with paper-based processes.

- 16-06-2021

Mobile Work Order Management Transforms Maintenance for CBH Group

Thirty thousand work orders is a lot of paper.